Automatic production line capable of achieving operation from pressing to sintering of magnetic shoes and implement method thereof

An automatic production line and magnetic tile technology, applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of large labor usage, large floor space occupied by equipment arrangement, fragile blanks, etc., and improve the consistency of quality , Occupying a small floor area and occupying a small floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

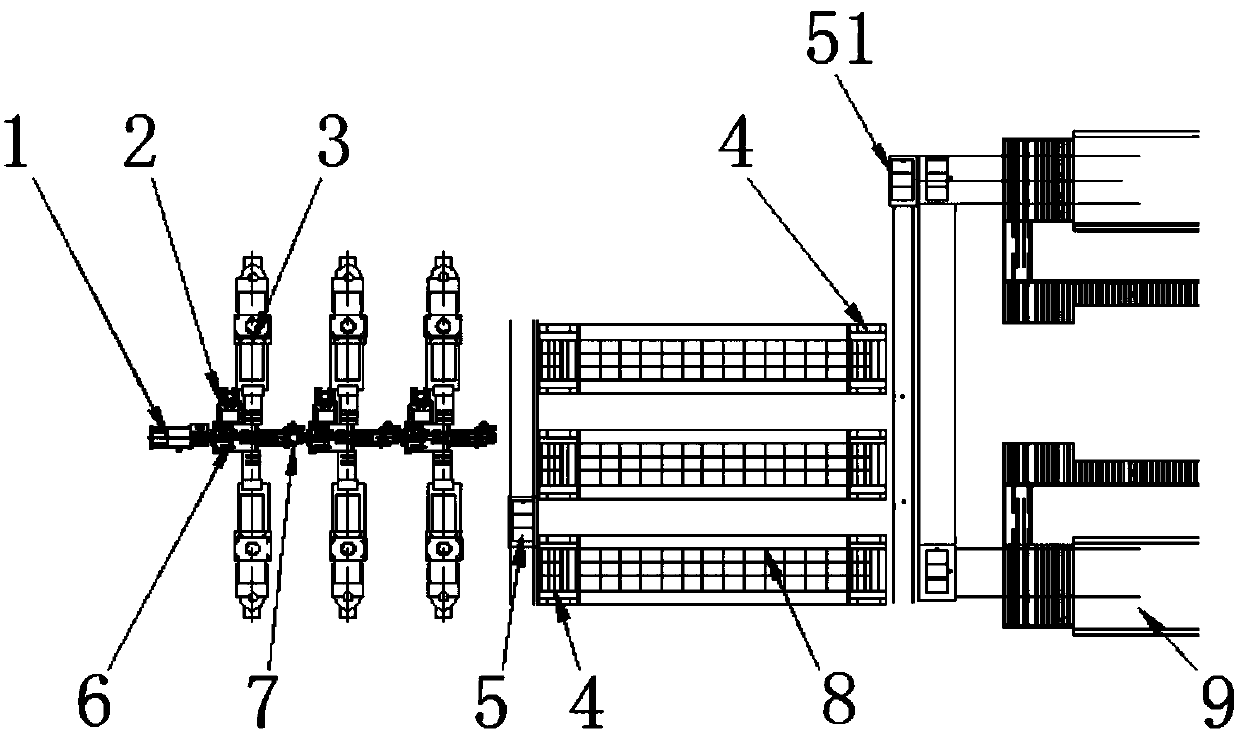

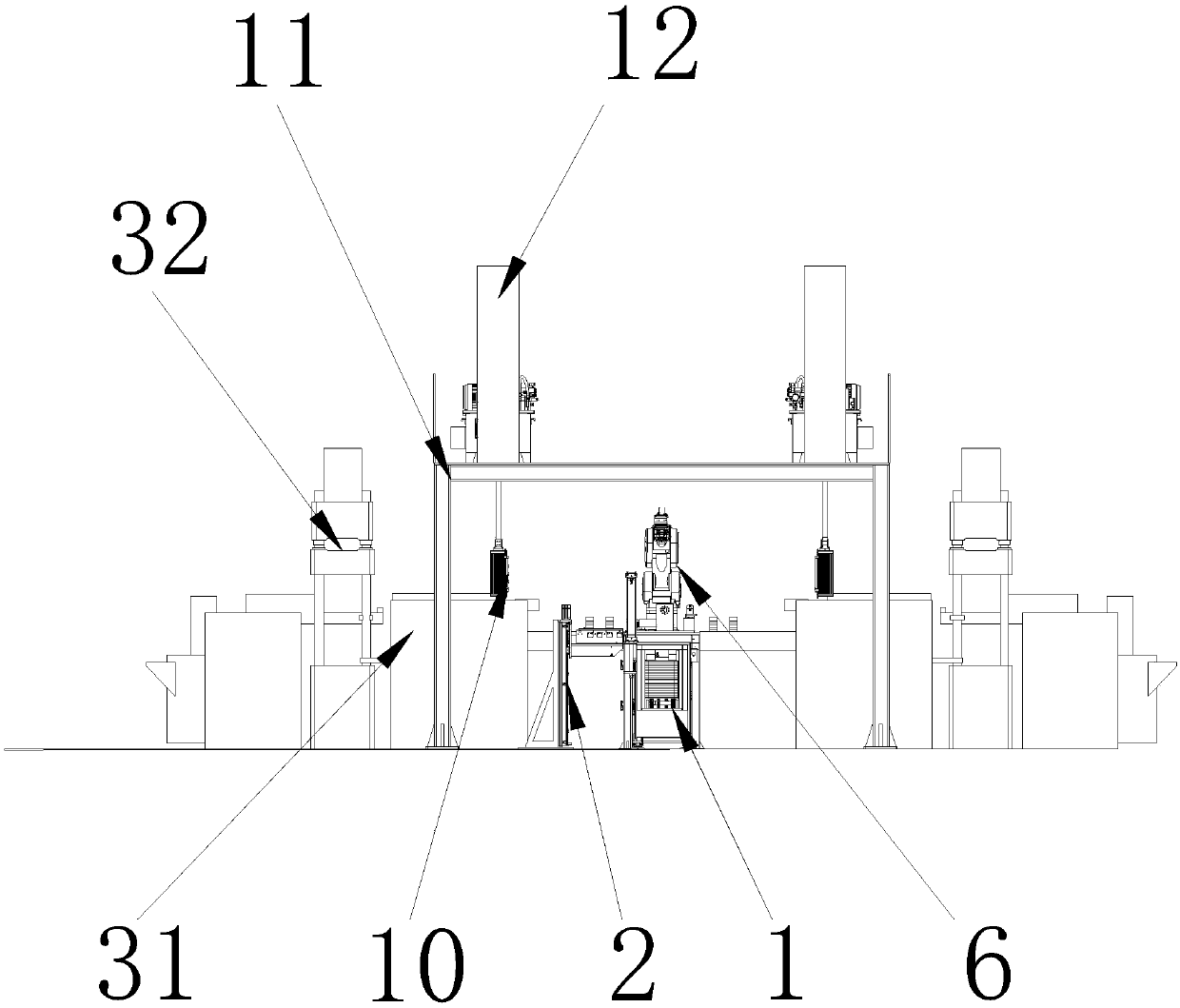

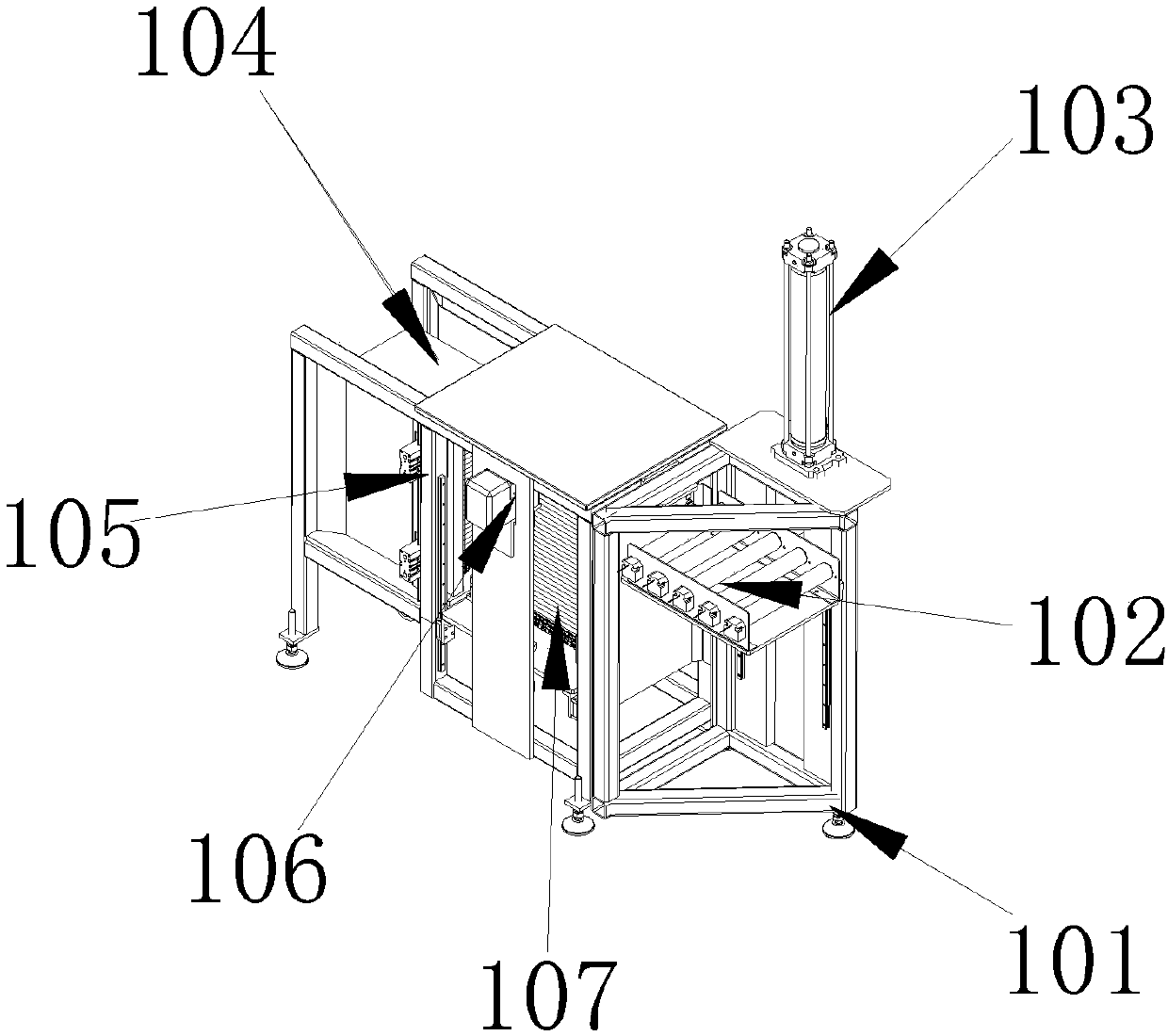

[0040] see Figure 1-10 , the present invention provides the following technical solutions: an automatic production line for magnetic tile pressing to sintering, including a board dismantling machine 1, a solid board exchange table 2, a press blanking mechanism 3, a lifting table 4, a rail car 5, and a robot bristle Stabbing mechanism 6, double-layer conveying line 7, intelligent warehouse 8, kiln 9, operation panel 10, overhead platform 11, electric cabinet and press oil tank 12; among them, the side of the board removal machine 1 is provided with a solid board exchange Table 2, a robot brush burr mechanism 6 is arranged on the top of the empty board exchange table 2, and a press blank removal mechanism 3 is arranged on the side of the robot brush burr mechanism 6, and a number of press blank removal mechanisms 3 are provided. The machine billet removal mechanism 3 is symmetrically designed side by side, and the middle position of the two rows of press billet removal mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com