Rotary-type water decanter

A decanter and rotary technology, which is applied in the field of rotary decanters, can solve the problems that the decanting flow and skimming effect are affected by wind and waves, the structure of the driving device and the transmission device is complicated, and the decanting is uneven. Compact, rigid, and evenly decanted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

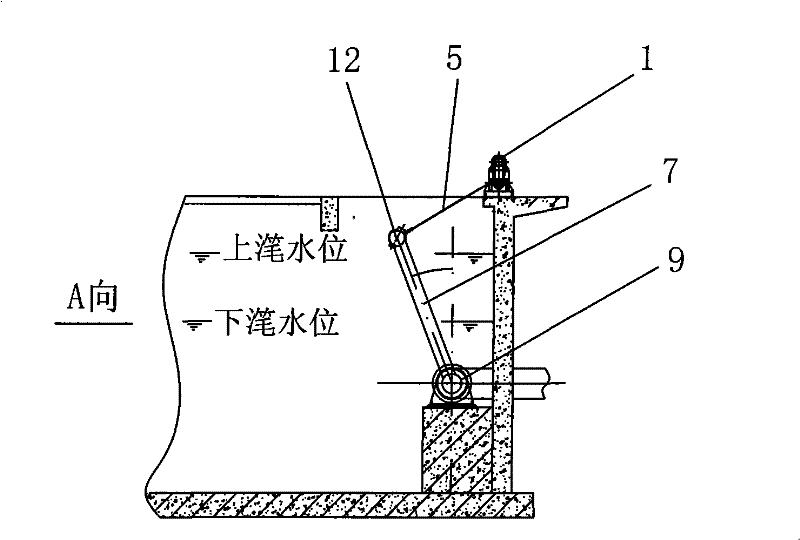

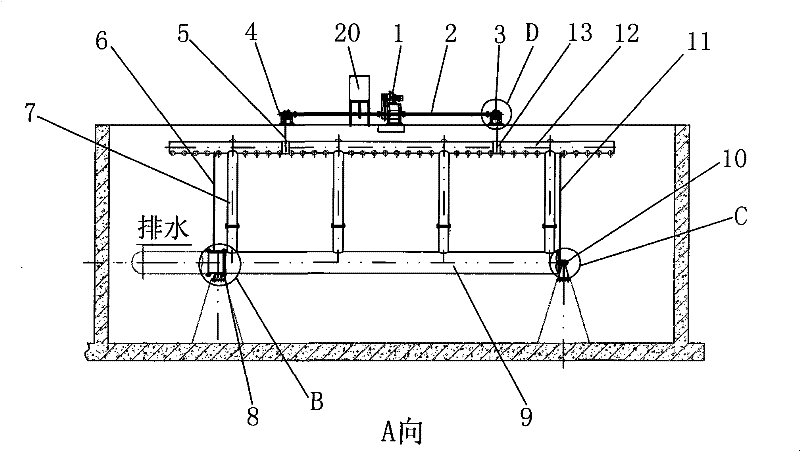

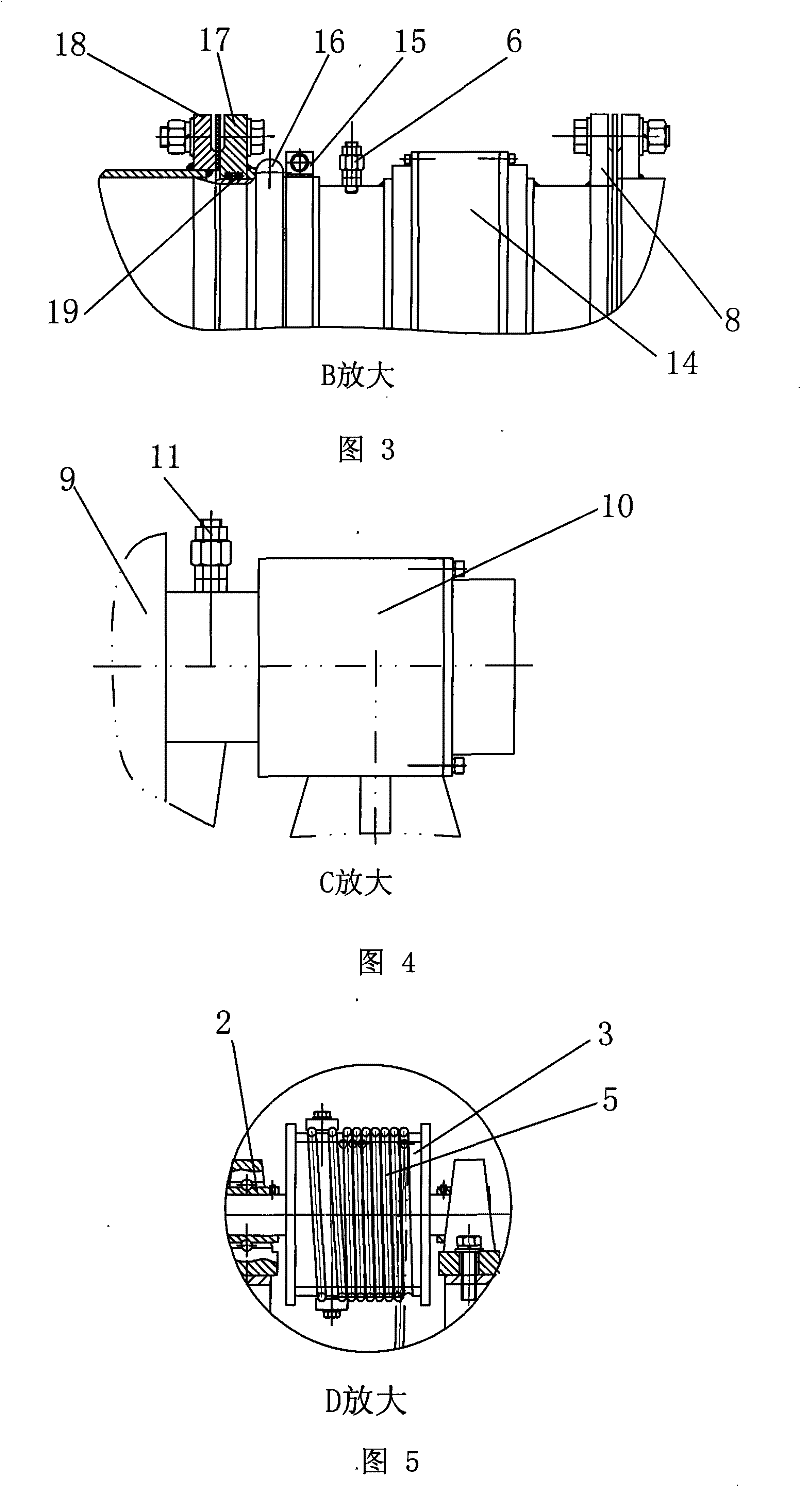

[0030] Example 1, such as figure 1 , 2 , 3, 4, and 5, a rotary decanter, including a driving device connected to a transmission device, a decanting tube group with one end connected to the transmission device and the other end hinged on the support of the pool, and a control system for controlling the operation of the driving device; The control system includes a stroke sensor 4 and a field control box 20 . The transmission device includes a reel 3 and a flexible rope 5 thereon. The set of decanting water pipes includes decanting water pipes 12 , at least one drainage branch pipe 7 and water outlet pipe 9 which communicate with each other. A row of water inlet holes is arranged at the bottom of the decanting pipe 12 .

[0031] The joint point of the lower end of flexible traction rope belt 5 and decanter is above the water surface all the time.

[0032] In order to lubricate and seal the underwater components, a first water diversion pipe 6 and a second water diversion pip...

Embodiment 2

[0034] Embodiment 2, in order to be suitable for decanting water in large pools, a transmission shaft 2 parallel to the decanting tube group is set between the driving device coupling transmission device; the two ends of the transmission shaft 2 are respectively provided with a reel 3 and its The transmission device of the flexible rope belt 5 on. All the other are with embodiment 1.

[0035] The working principle of the present invention: the motor direct-connected reducer in the driving device transmits the rotary motion to the two reel groups synchronously, and pulls the decanter pipe, water diversion pipe, central drain pipe, and PO combined seal around the pipe center line of the water pipe group 9 to work Rotational movement. The closed-loop control system composed of the on-site control box 20 and the stroke sensor 4 adjusts the rotation speed and direction in good time according to the set program to realize the following actions: the driving device 1 drives the reel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com