Pipeline sludge solidification treatment equipment and construction method thereof

A technology for solidification treatment and sludge, applied in the direction of fixed/solidified sludge treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of lack of strength, damage to the natural environment, fixed amount of addition, etc., to achieve flexible disassembly and cleaning, guarantee Uniformity and even mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

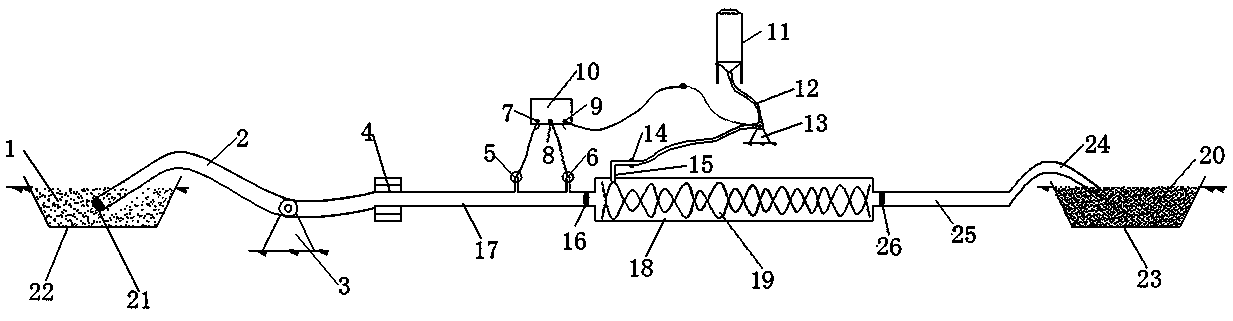

[0033] In a river dredging project in Wenzhou, since there is no storage yard nearby for the cleared silt, if it is transported over a long distance, it will increase the freight and pollute the environment, so the silt needs to be solidified and directly used as embankment materials for adjacent projects. The water content of the silt is greater than 102%, and the specific gravity of the silt is 1.53 t / m 3 , the 90-day-old unconfined compressive strength of the solidified silt soil must reach 1200 kPa, and the moisture content must reach 38%; therefore, the implementation method is as follows:

[0034] 1. The moisture content of the silt on site is greater than 85%, so the silt slurry adjustment tank is omitted;

[0035] 2. According to the design strength requirements, carry out the mixing ratio test on the silt-solidified soil, and determine that the water-cement ratio of the slurry is 0.3. According to the water-cement ratio, store the prepared curing agent slurry in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com