Biomass gasification furnace

A gasification furnace and biomass technology, applied in the direction of gasification process, gasification device details, gasification device feeding tools, etc., can solve the problems of poor internal air circulation, low gasification rate, small contact surface, etc., to achieve Ease of heating and gasification, high gasification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

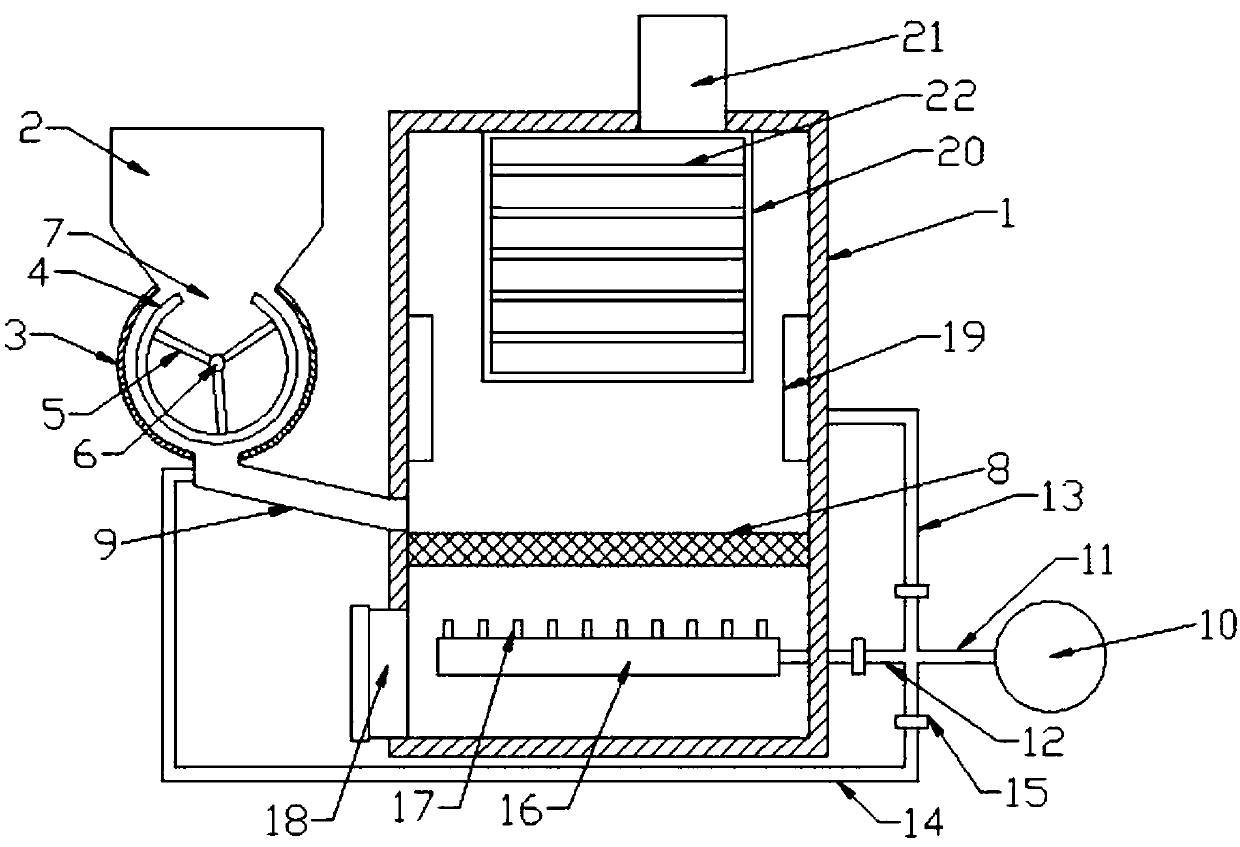

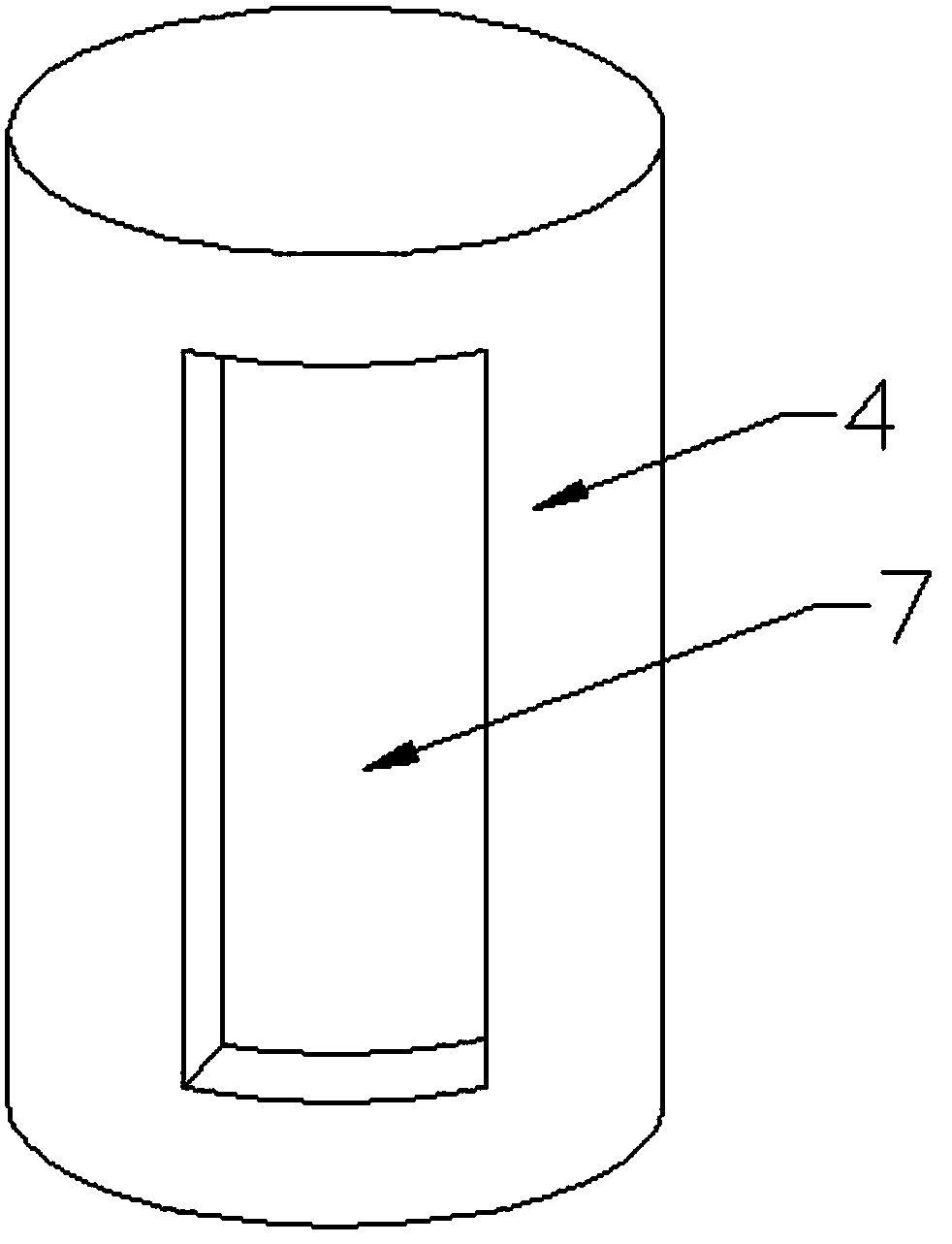

[0014] Please refer to the figure, in the embodiment of the present invention, a biomass gasification furnace includes a furnace body 1, a feed hopper 2, a feeding box 3, a furnace grate 8 and a fan 10; the furnace grate 8 is arranged in the furnace Inside the body 1, a feeding pipe 9 is connected to the side wall of the furnace body 1 corresponding to the top of the furnace grate 8, and the feeding pipe 9 is arranged obliquely, and the other end is connected to the feeding box 3, and the end where the feeding box 3 is located is high. At the other end, make the fuel in the lower material box 3 enter the furnace body 1 along the lower material pipe 9; Fuel; the lower material box 3 is a horizontal cylindrical structure, and a horizontal rotating cylinder 4 is coaxially arranged in the lower material box 3, and the distance between the outer wall of the rotating cylinder 4 and the inner wall of the lower material box 3 is less than 3mm. To reduce fuel falling from the gap, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com