Spore-print making box and method for field preparation of large fungal spore print by using same

A spore and box body technology, which is applied in the field of spore print making boxes, can solve the problems of damaged spore print, poor spore print effect, easy to fall off absorbent paper, etc., and achieves the effect of convenient operation, good production effect, and convenient portability at any time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

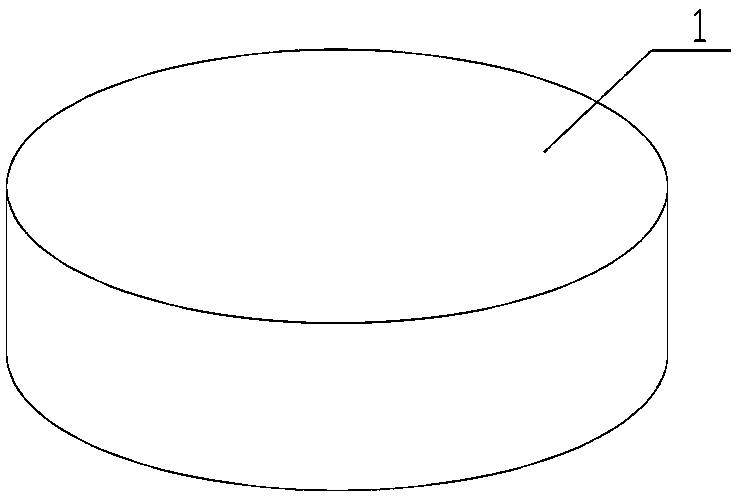

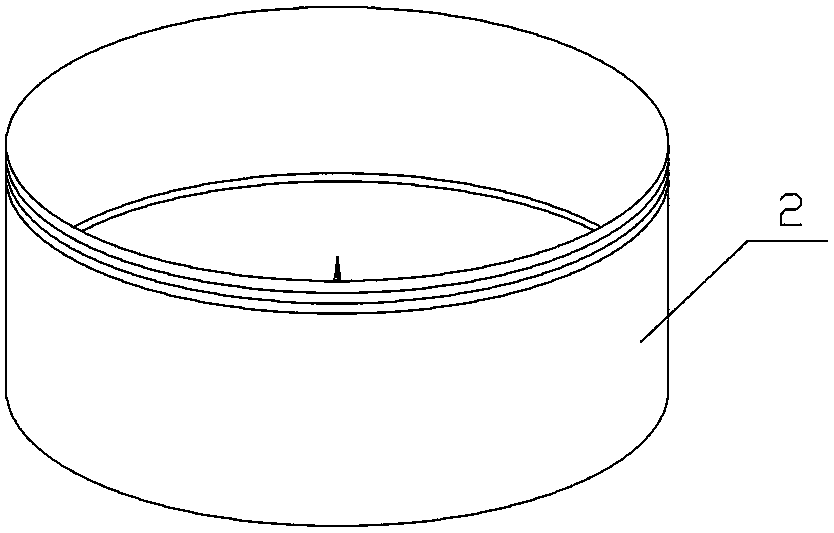

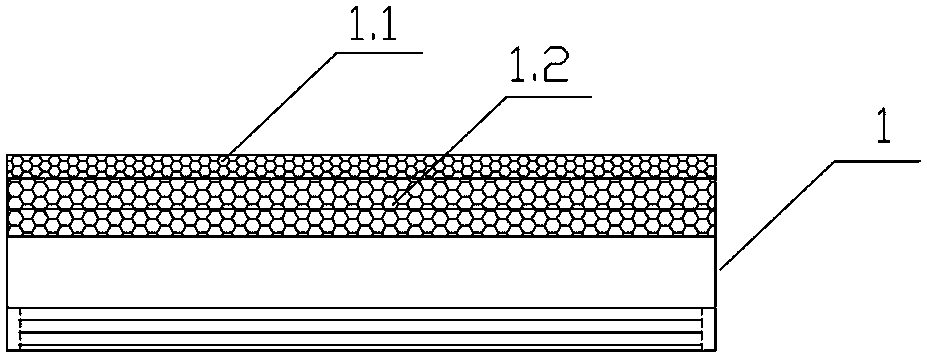

[0025] Such as Figure 1~5 As shown, the spore printing production box of the present invention includes a box body 2 with a loam cake 1, and the loam cake 1 and the box body 2 are movably connected by mutually matching threads (or buckles). Sponge layer, the water-absorbing sponge layer includes a fixed sponge layer 1.1 (thickness is about 0.5mm) that is close to the inner surface of the upper cover 1. If necessary, one or 2~3 layers of adjustment sponge layers can be placed on the fixed sponge layer 1.1 1.2 (the thickness of each layer of sponge layer is also adjusted to be about 0.5mm); the center of the supporting plate 2.1 horizontally arranged in the box body 2 extends upwards and is provided with a hexagonal pyramid structure fixing pin 2.2 with an upward tip, which is placed on the supporting plate 2.1 The center of the spore printing paper 2.3 is set on the fixed needle 2.2, the spore printing paper 2.3 can be made of thicker and difficult-to-absorb circular paper, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap