Novel high-performance aluminum alloy material and preparation method thereof

An aluminum alloy material and high-performance technology, applied in the field of aluminum alloy, can solve the problems of different specifications and quantities of raw materials, waste of cost resources, large price fluctuations, etc., and achieve the effect of reducing the detection burden, fine planning, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

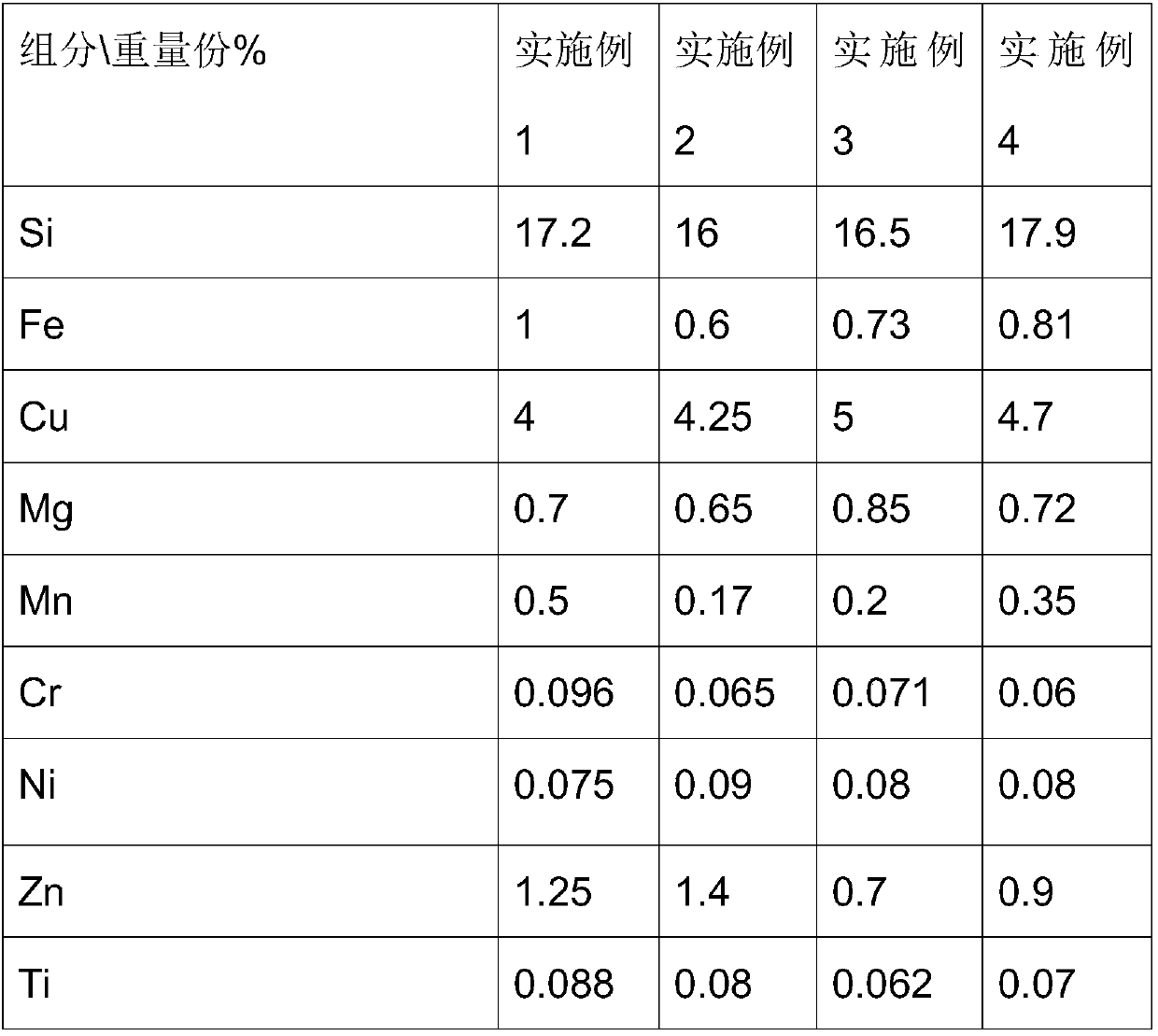

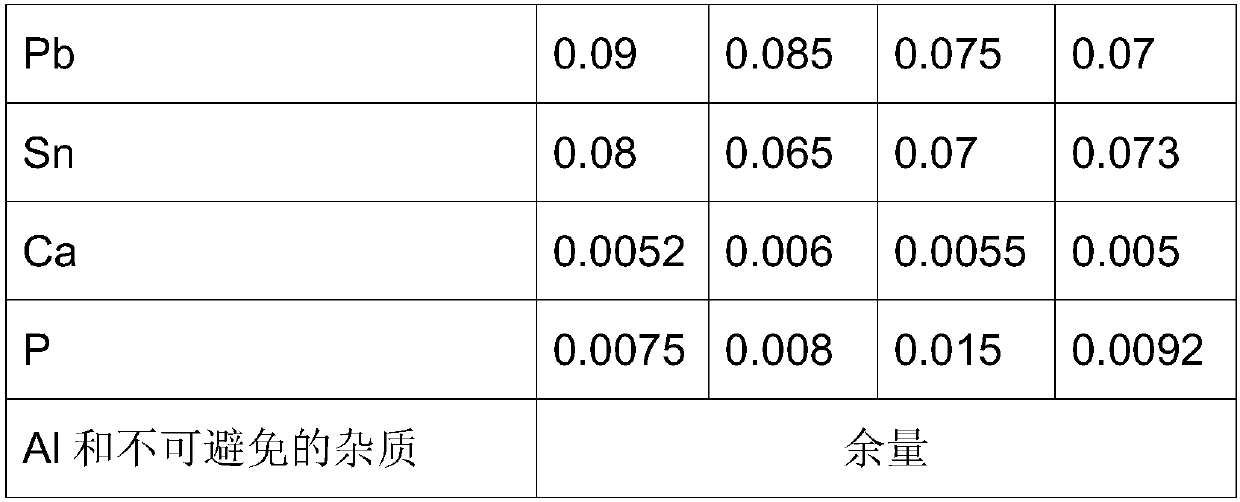

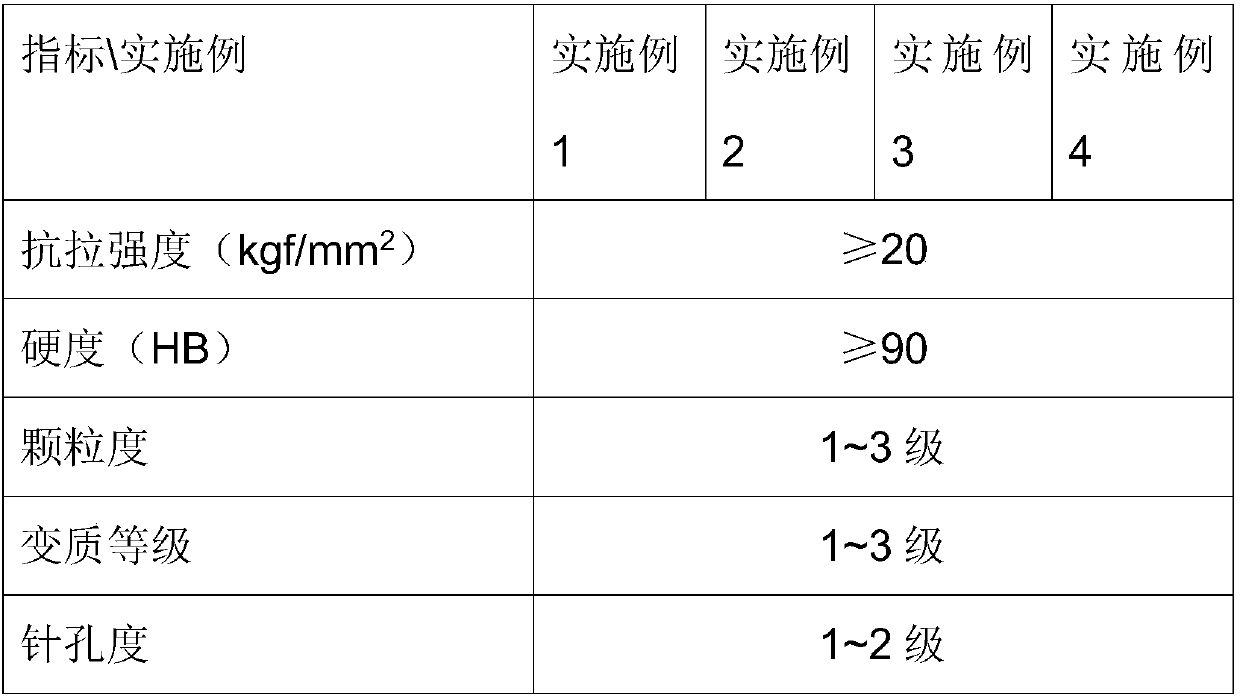

[0022] In order to explain the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below. A new type of high-performance aluminum alloy material, including parts by weight involved in the examples in Table 1.

[0023] Table 1 Examples of components (unit: weight %)

[0024]

[0025]

[0026] A preparation method of a new high-performance aluminum alloy material includes the following steps:

[0027] (1-1) One-time silicon melting: silicon is melted once after the aluminum soup is formed, the liquid level test and the weight of the aluminum soup are confirmed before the silicon is melted, the weight of the aluminum soup is determined, and the temperature of the aluminum soup is controlled at 780~800℃; Before the operation, carry out the iron raking operation. When melting the silicon, first put in 1~2‰ of phosphorous copper, and then melt the metal silicon. The melted metal silicon is 553 metal si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com