On-line preparation method for quick-drying yarn in embedded type composite spinning

A composite spinning and embedded technology, applied in textiles and papermaking, liquid-repellent fibers, fiber treatment, etc., can solve the problems of prolonging the production cycle and increasing production costs, and achieve the effect of improving the quick-drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

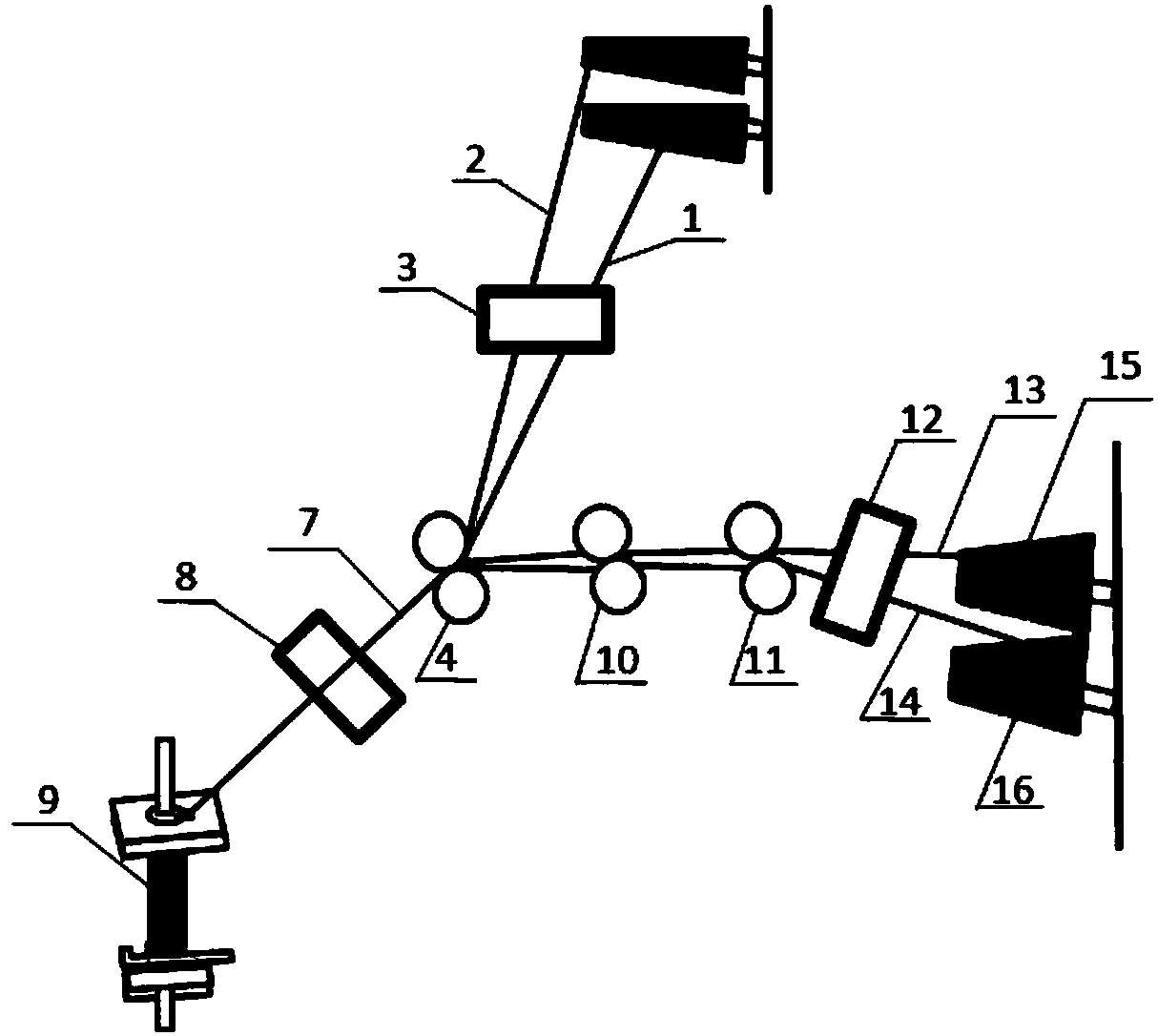

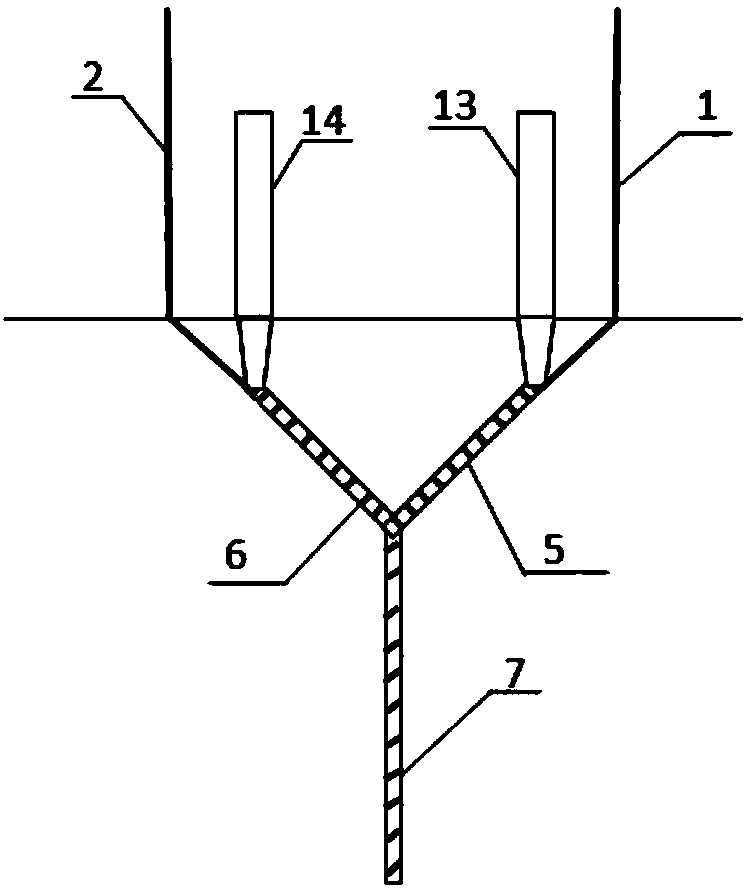

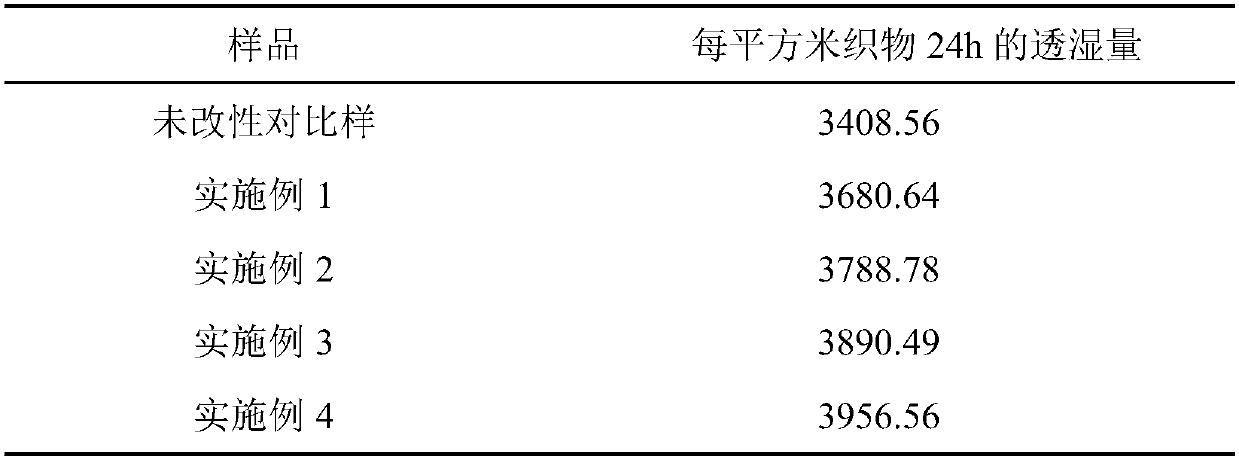

[0014] On the ring spinning frame, the first polyester filament and the second polyester filament run are provided with the first modification device, the first cotton roving and the first cotton roving between the first cotton roving reel and the second cotton roving reel to the rear roller. The second modification device is set at the running path of the second cotton roving. The first modification device and the second modification device are composed of a flow control device and a wetting device. The flow control device can be a syringe pump, and the wetting device can be a sponge. The wetting device, the hose connection between the flow control device and the wetting device, the flow control device adjusts the flow rate of the modified liquid, the first wetting device applies a hydrophilic finishing agent to the two polyester filaments, the second wetting device A hydrophobic finish was applied to two cotton rovings. The hydrophilic finishing agent is made by mixing absol...

Embodiment 2

[0016]On the ring spinning frame, the first polyester filament and the second polyester filament run are provided with the first modification device, the first cotton roving and the first cotton roving between the first cotton roving reel and the second cotton roving reel to the rear roller. The second modification device is set at the running path of the second cotton roving. The first modification device and the second modification device are composed of a flow control device and a wetting device. The flow control device can use a peristaltic pump, and the wetting device can use a sponge. The wetting device and the flow control device adjust the flow rate of the modified liquid. The first wetting device applies a hydrophilic finishing agent to the two polyester filaments, and the second wetting device applies a hydrophobic finishing agent to the two cotton rovings. The hydrophilic finishing agent is made by mixing absolute alcohol and fatty alcohol polyoxyethylene ether, the ...

Embodiment 3

[0018] On the ring spinning frame, the first polyester filament and the second polyester filament run are provided with the first modification device, the first cotton roving and the first cotton roving between the first cotton roving reel and the second cotton roving reel to the rear roller. The second modification device is set at the running path of the second cotton roving. The first modification device and the second modification device are composed of a flow control device and a wetting device. The flow control device can be a syringe pump, and the wetting device can be a sponge. The wetting device and the flow control device adjust the flow rate of the modified liquid. The first wetting device applies a hydrophilic finishing agent to the two polyester filaments, and the second wetting device applies a hydrophobic finishing agent to the two cotton rovings. Wherein said hydrophilic finishing agent is formed by mixing absolute ethanol and fatty alcohol polyoxyethylene ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com