Polyurea rebar self-protection anti-corrosion concrete block

A concrete block, anti-corrosion technology, applied in the direction of coastline protection, etc., can solve the problems of reduced structural strength, reduced structural durability, corrosion of steel bars, etc., and achieve excellent physical properties, good thermal stability, and anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

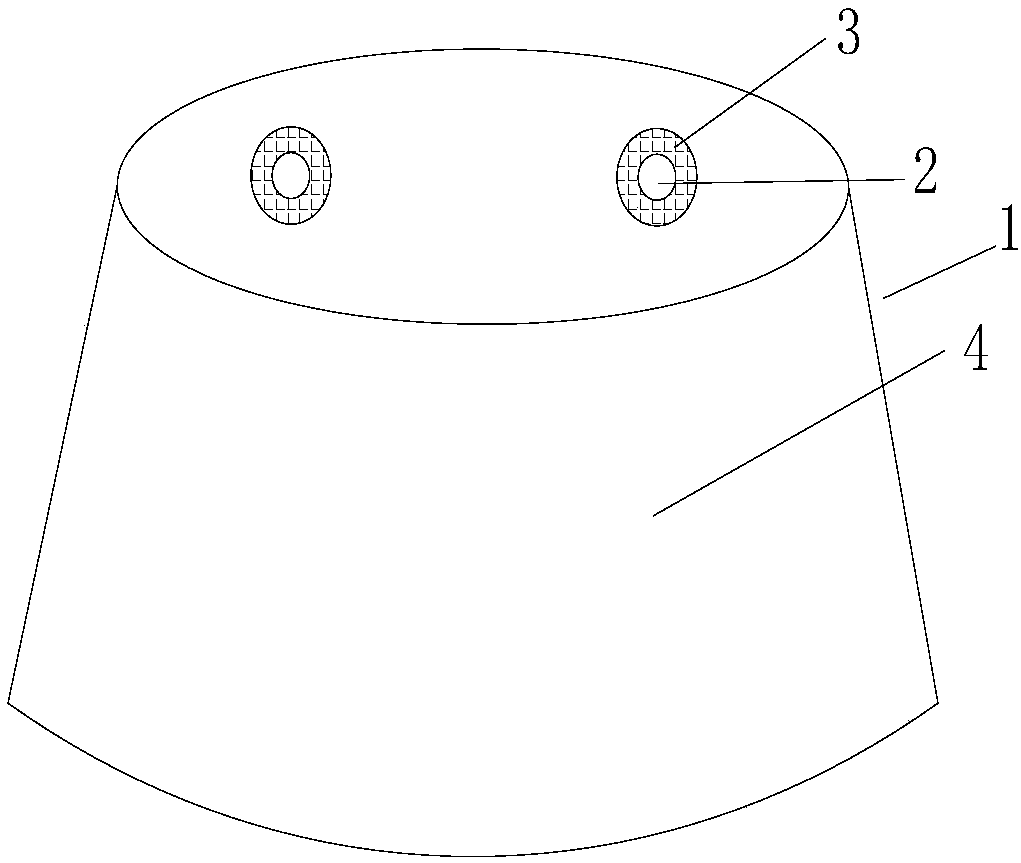

[0017] A polyurea steel bar self-protection anti-corrosion concrete block 1 comprising steel bars 2 and concrete 4, and a polyurea protective layer 3 is provided on the outer layer of the steel bars.

Embodiment 2

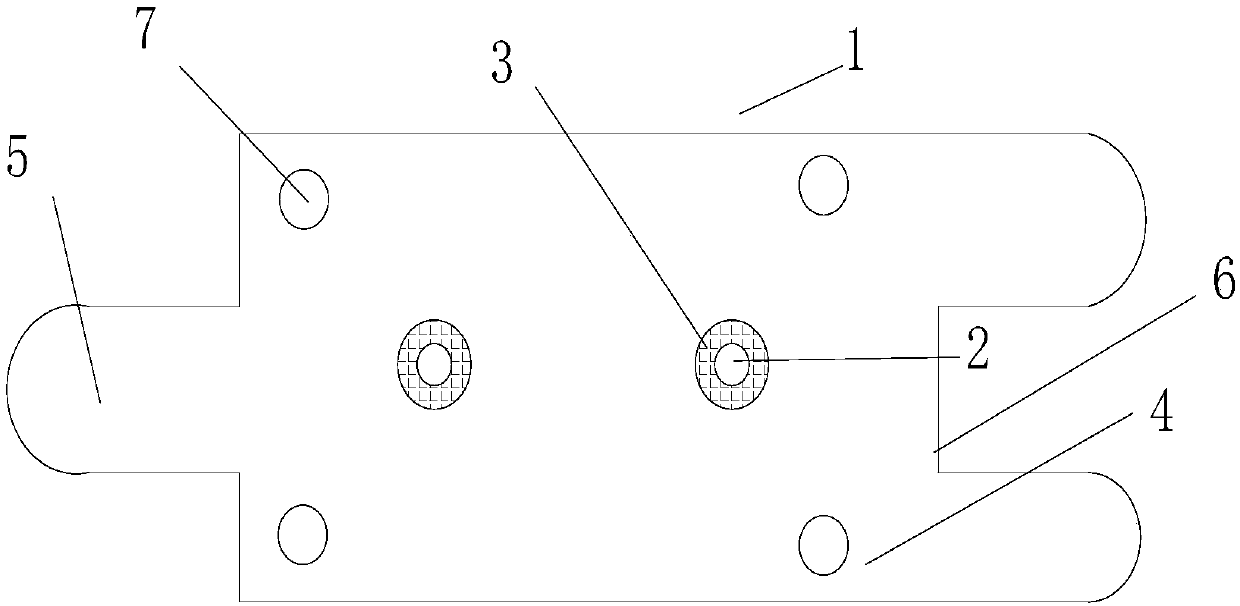

[0019] A polyurea steel bar self-protection anti-corrosion concrete block 1 comprising steel bars 2 and concrete 4, the outer layer of the steel bars has a polyurea protective layer 3, the left side of the block has an outrigger 5, and the right side has In the inner groove 6, the polyurea steel self-protecting anti-corrosion concrete block may have a through hole 7, and the cross section of the through hole is circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com