Selective inflow controller and well completion pipe string comprising same

A controller and selective technology, applied in drilling pipes, casings, production fluids, etc., can solve the problems of low fluid identification accuracy, unstable performance, and difficult processing, so as to improve oil well production, maintain balance, prevent The effect of bottom water rushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

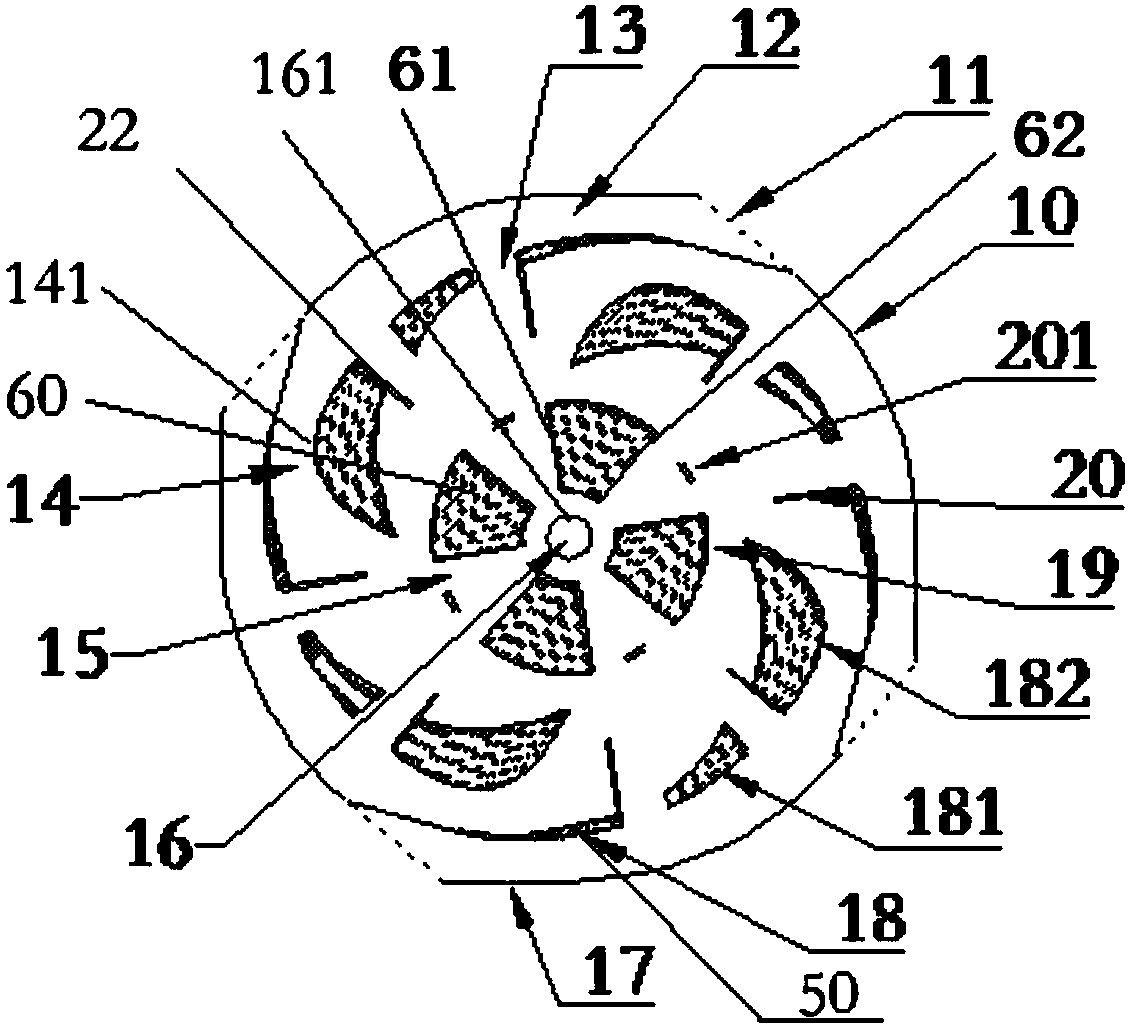

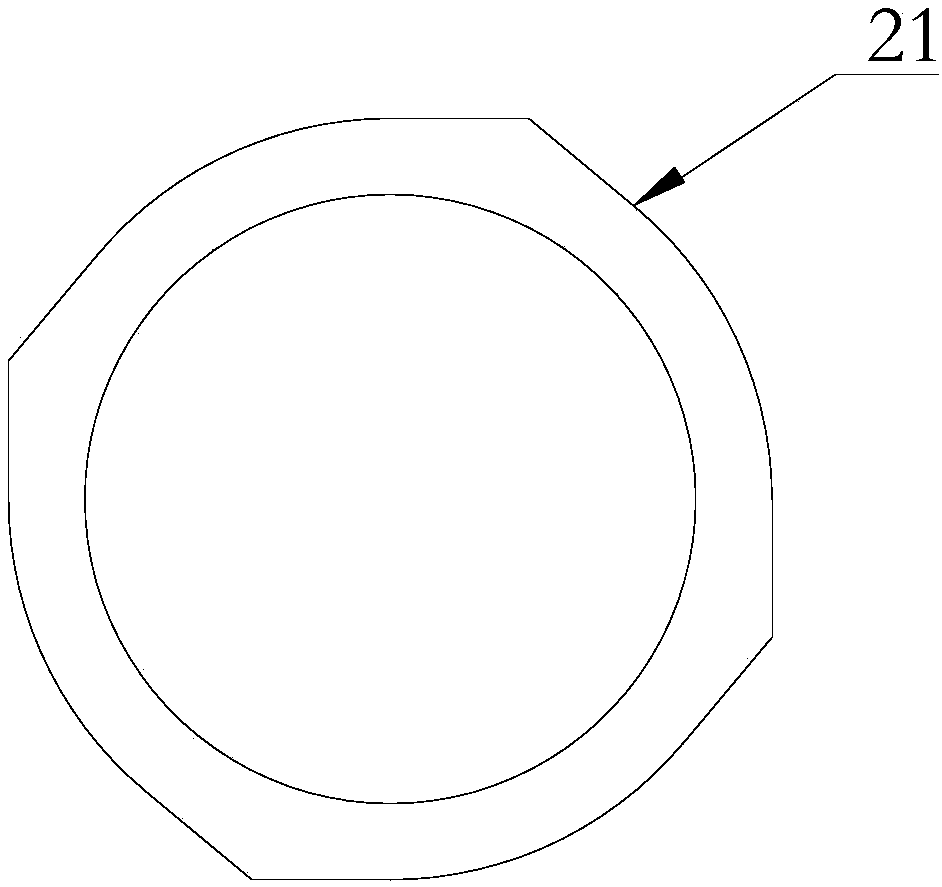

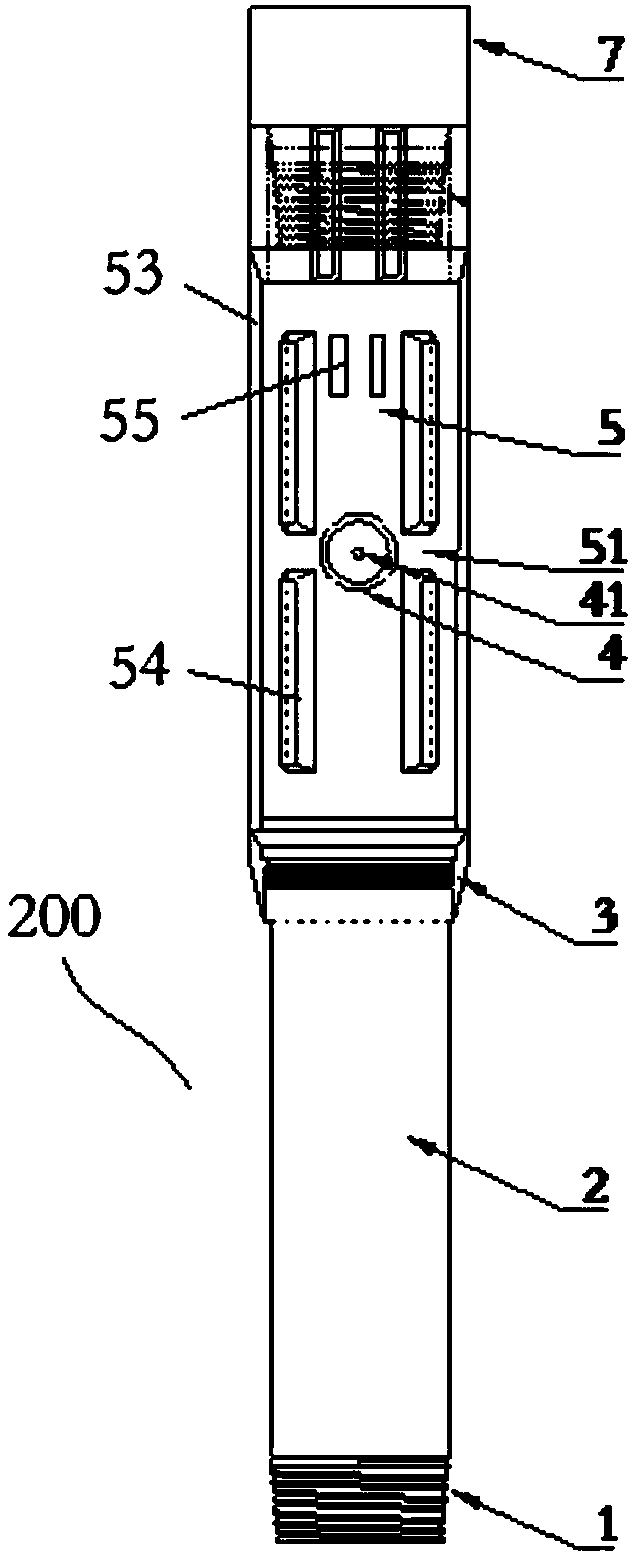

[0031] figure 1 A selective inflow controller 100 according to the present invention is shown. Such as figure 1 As shown, the controller 100 includes a controller body 10 and a cover plate 21. The controller body 10 is configured as a rotationally symmetrical bar-shaped protrusion structure, and the cover plate 21 is sealed at the opening of the controller body 10 to form a seal. The inner cavity of the controller 100. There is an inlet 11 on the side wall of the controller body 10 for introducing fluid. A deflector block assembly 50 is disposed on the bottom surface of the controller body 10 . The deflector block assembly 50 has a first deflector block 18 , a second deflector block 181 , and a third deflector block 182 . A first radial liquid baffle 20 is provided at the downstream end of the first deflector block 18 . A second radial liquid baffle 22 is provided at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com