Automobile differential

A kind of technology of automobile differential and casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

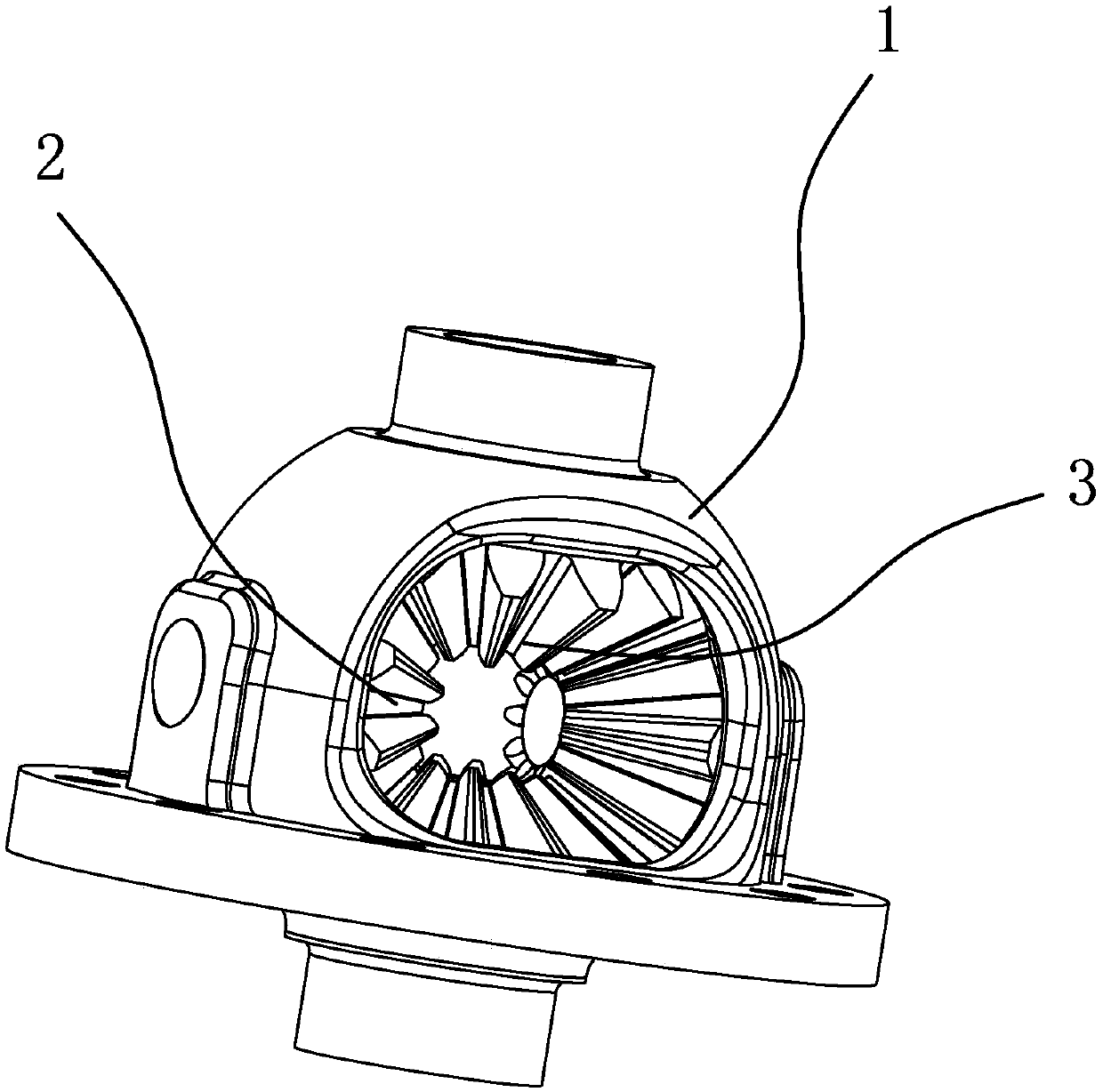

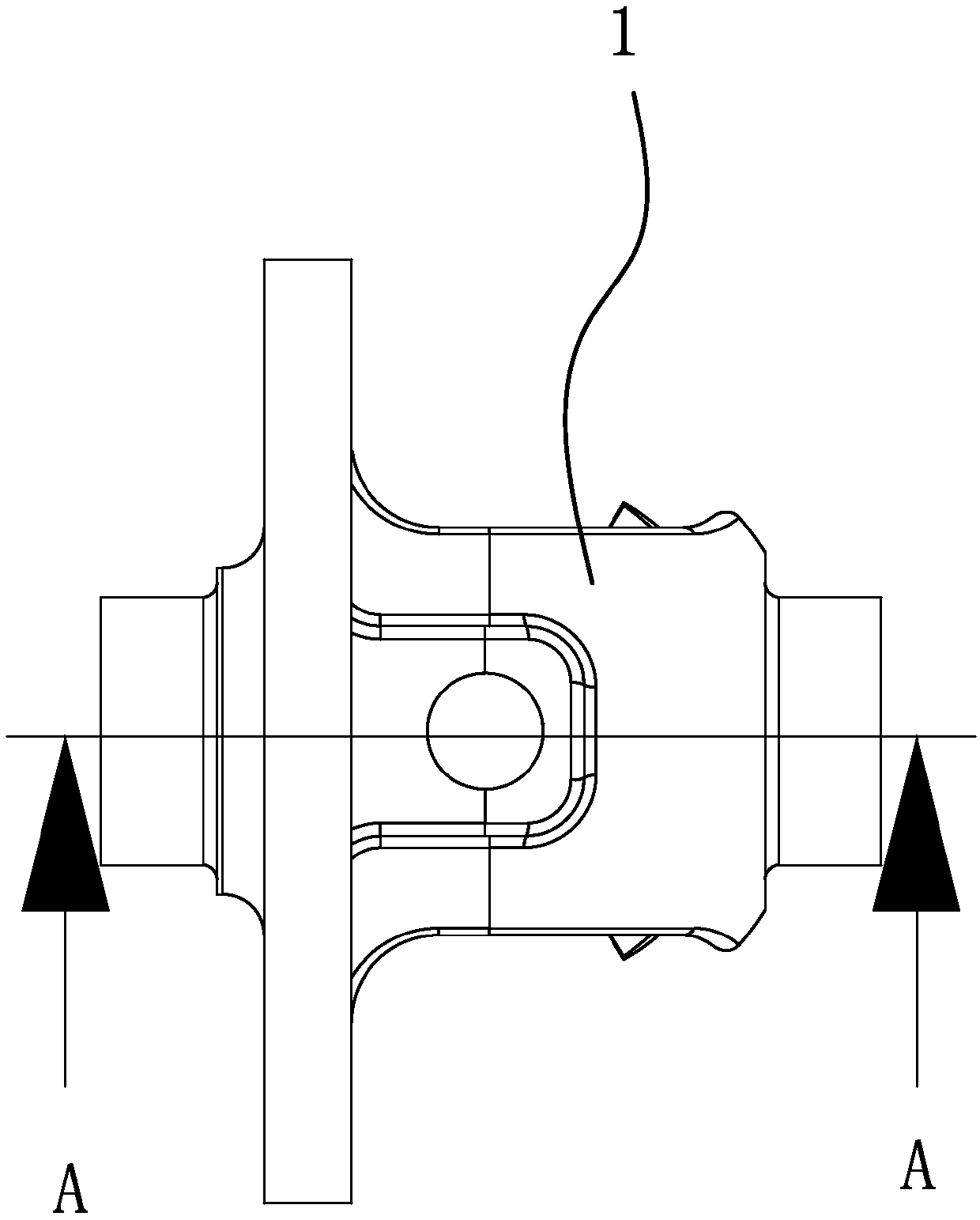

[0028] Such as Figure 1-4 As shown, the automobile differential includes a housing 1, a half-shaft bevel gear 3 and a planetary bevel gear 2 all arranged in the housing 1, the housing 1 is an integral structure, and the housing 1 is provided with a shaft hole 1c .

[0029] There are two half-shaft bevel gears 3, and the two half-shaft bevel gears 3 are arranged oppositely and are both rotatably connected in the housing 1. The contact surfaces between the two half-shaft bevel gears 3 and the housing 1 are all conical surfaces. A gasket 4 is also provided between the bevel gear and the housing 1 , and the shape of the gasket 4 is a conical shape matching the contact surface of the side shaft bevel gear 3 and the housing 1 . According to actual needs, the contact surface can be designed as a plane or a spherical surface.

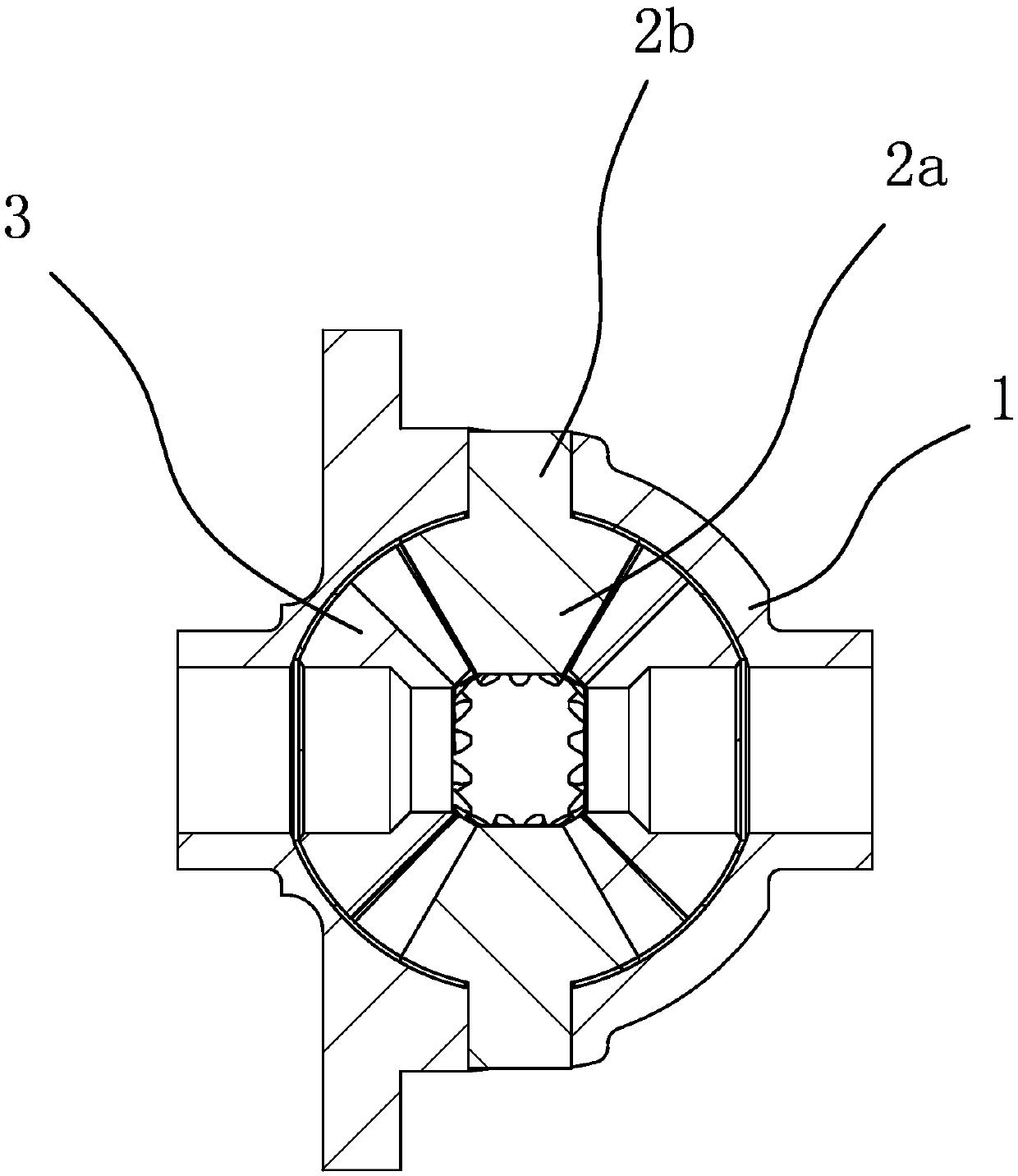

[0030]The planetary bevel gear 2 comprises a wheel shaft portion 2b and a solid conical gear portion 2a, the wheel shaft portion 2b is connected to the larg...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 5 and 6 As shown, the housing 1 includes a front shell 1a and a rear shell 1b, the front shell 1a and the rear shell 1b are respectively provided with a half hole 1c1 and a half hole 2 1c2, the front shell 1a and the rear shell 1b are fixed by fasteners 5 and Half hole one 1c1 and half hole two 1c2 encircle to form shaft hole 1c. When installing, first place one of the side bevel gears 3 and the corresponding gasket 4 at the installation position corresponding to the rear shell 1b through loose fitting, then put the gasket 4 on the two planetary bevel gears 2, and place the wheel shaft part 2b In the half hole 1c2 of the rear shell 1b, the gear part 2a is kept in mesh with the side gear, and then the front shell 1a that has assembled another half shaft bevel gear 3 and the gasket 4 is covered, and the front shell 1a is fixed by the fastener 5. The shell 1a and the rear shell 1b are fi...

Embodiment 3

[0035] This embodiment is basically the same as Embodiment 1, the difference is that a bearing is fixed in the shaft hole 1c, and the axle part 2b passes through the inner ring of the bearing and is fixed with the inner ring of the bearing, which makes the installation more convenient and stable. better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com