A special reducer for small diameter and high torque screw pump

A high-torque, screw pump technology, applied in pump components, machines/engines, gear vibration/noise attenuation, etc., can solve problems such as low structural strength of planetary gears, unreasonable overall design of reducers, and smaller planetary gear modules. , to solve the problem of insufficient design space, improve strength and service life, and shorten the slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

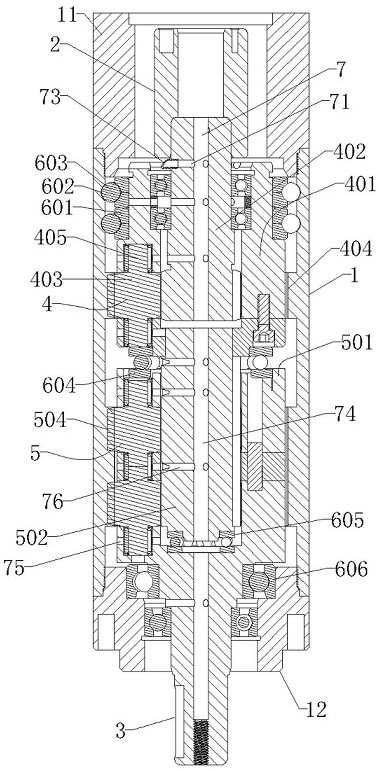

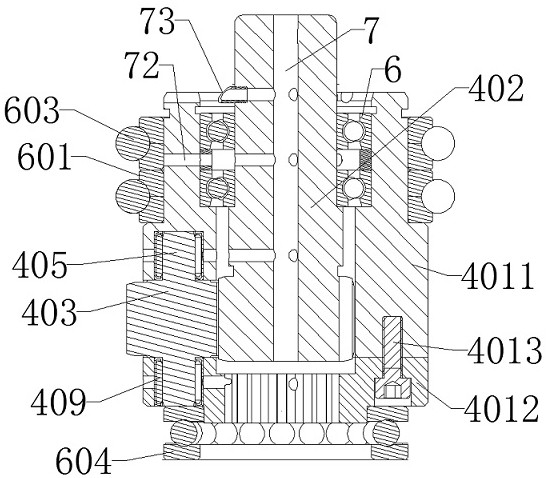

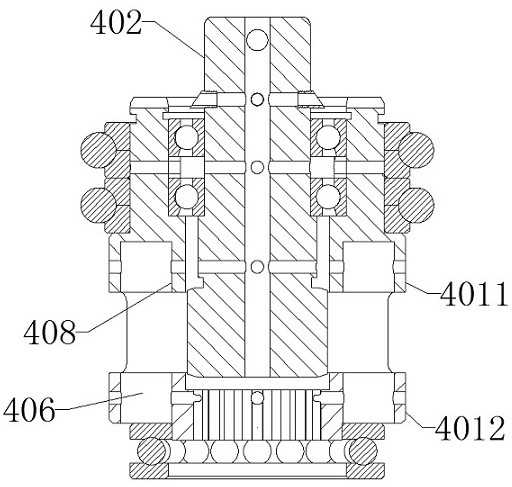

[0037] Example: see Figure 1-8, a special reducer for small-diameter and large-torque screw pumps, comprising a casing 1, and a power input end 2 and a power output end 3 are arranged coaxially in the casing 1 near its two ends, and the casing 1 is provided with a power input end 2 and a power output end 3. There is a first-stage planetary gear reduction assembly 4 that is drivingly connected to the power input end 2 , and the casing 1 is provided with a second-stage planetary gear reduction assembly 5 that is drivingly connected to the power output end 3 . The first-stage planetary gear reduction The assembly 4 and the second-stage planetary gear reduction assembly 5 are connected in a transmission, and the housing 1 is installed with a power input end 2, a power output end 3, a first-stage planetary gear deceleration assembly 4 and a second-stage planetary gear deceleration. Assembly 5 is a bearing device that rotates coaxially.

[0038] The first-stage planetary gear redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com