Piston crankshaftless engine

An engine, crankless technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve the problems of complex movement mode, complex structure of moving parts, etc., to achieve the effect of simple replacement of parts and simplification of constituent elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and specific embodiment, technical scheme of the present invention is described further:

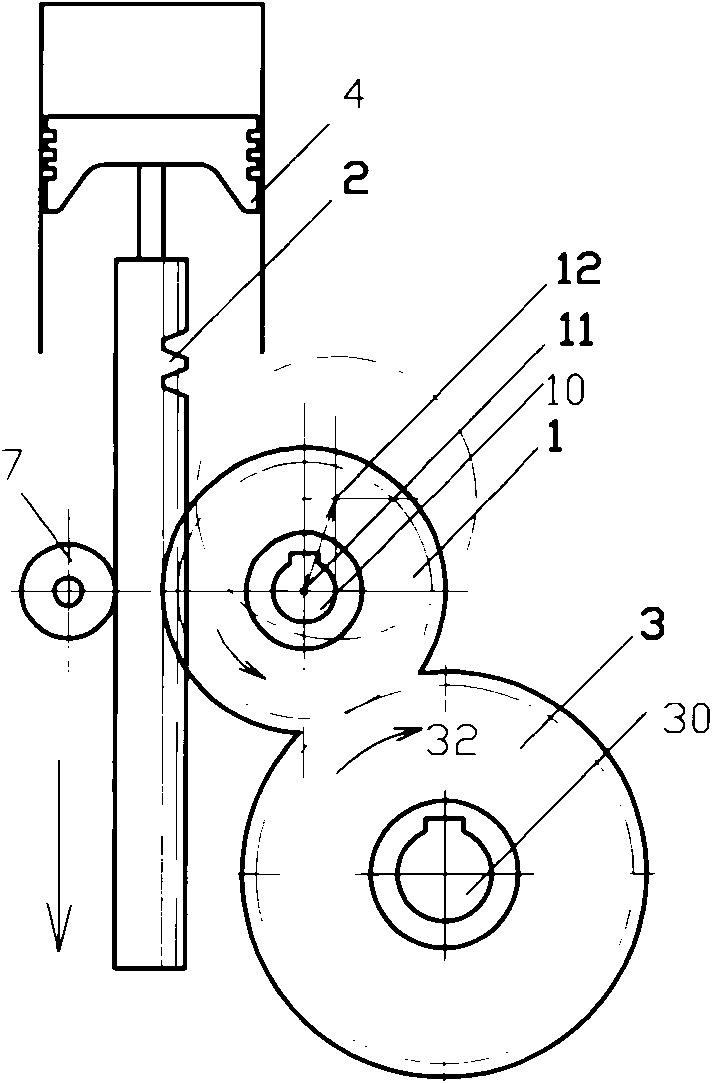

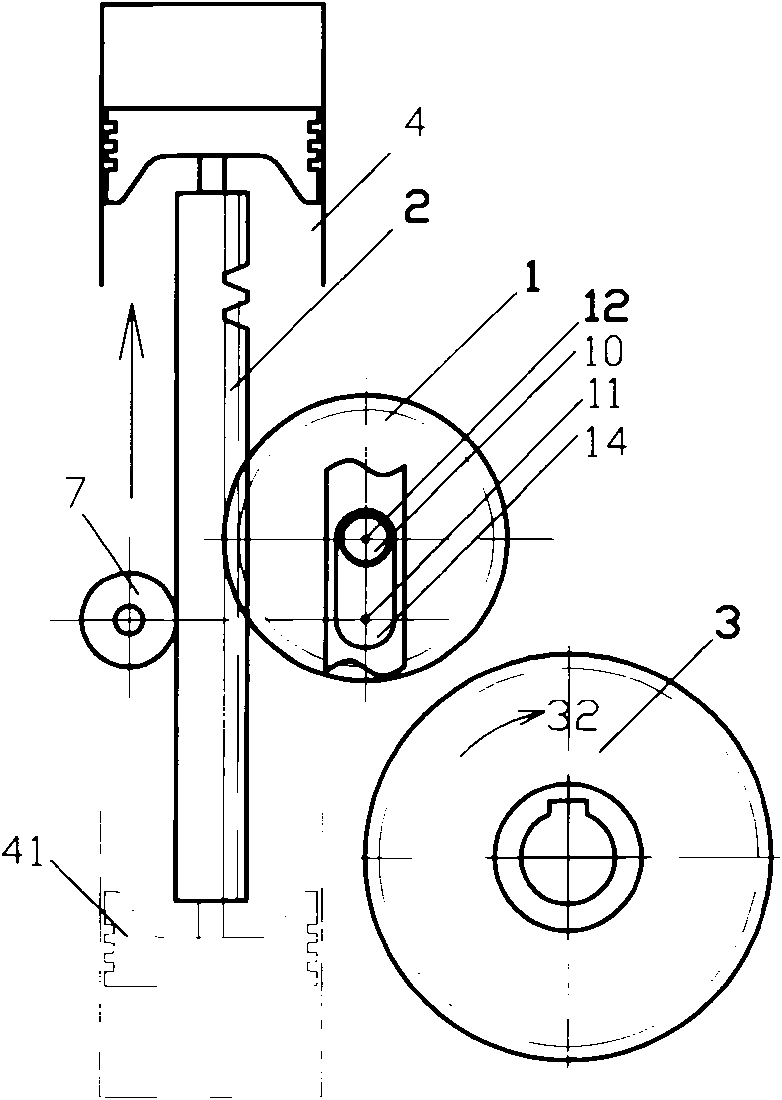

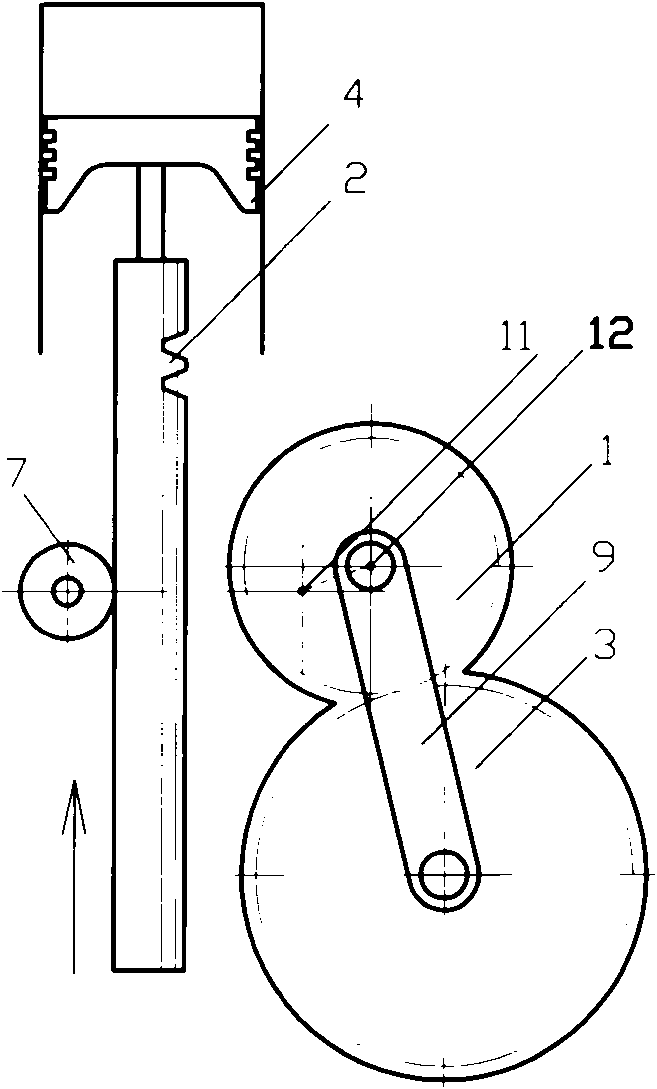

[0044] 1. If figure 1 Is a typical embodiment, the core component - the mobile gear 1 can move between the "engagement" position 11 and the "non-engagement" position 12 . When the rigid member formed by the solid connection of piston 4 and rack 2 runs from the top dead center to the bottom dead center, the moving gear 1 moves to the "engagement" position 11, that is, the moving gear 1 is directly meshed with the rack 2, and at the same time it is also in contact with the drive The gear 3 is also directly meshed, so that the power transmission link among the piston 4, the rack 2, the moving gear 1, the driving gear 3, and the straight output spindle 30 is communicated. If the piston 4 is in the explosive stroke, its explosive power can follow the power The transmission chain is transmitted tangentially by the rack 2 to the moving gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com