Multi-combustor combined type steam injection boiler

A steam injection boiler and multi-burner technology, which is applied to steam boilers, steam generation, lighting and heating equipment, etc., to achieve the effects of reducing the incidence of accidents, improving operating efficiency, and adjusting the range of large heat loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] The present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings.

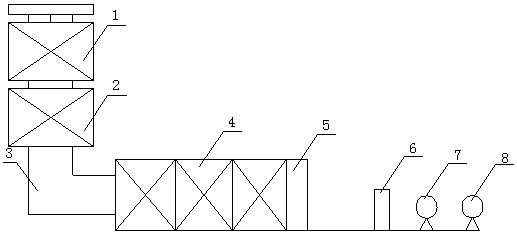

[0015] Such as figure 1 As shown, a multi-burner combined steam injection boiler of the present invention, the main components include a convection section 1, a superheating section 2, a transition section 3, a radiation section 4, a burner section 5, a control cabinet 6, a blower 7 and a plunger pump 8. Specifically, a burner section 5 is used in the radiant section 4, and the burner section 5 is composed of a plurality of burners. Since the operating load of the steam injection boiler depends on the demand for oil production, the operating load is wide (20% to 100%) and changes frequently. When the load of the steam injection boiler changes frequently, the combination of multiple burners can make the burner have a larger thermal load adjustment range and improve the operating efficiency. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com