Low-frequency array eddy current detection device and detection method for corrosion defects of steel pipe inner wall

An eddy current detection and array technology, applied in the direction of material magnetic variables, can solve problems such as boiler heating surface defects, and achieve the effect of improving detection accuracy and field work efficiency, easy operation, and improving defect resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

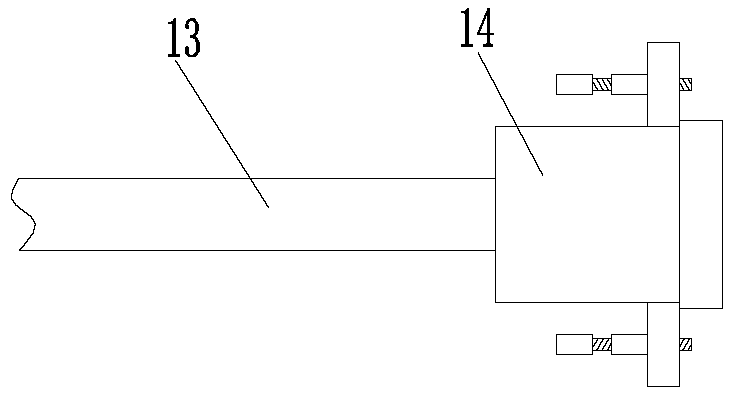

[0035] Depend on Figure 1-9 Provided is a low-frequency array eddy current detection device, which includes an eddy current detection host, a connecting wire and a low-frequency array eddy current probe; the eddy current detection host is connected to the low-frequency array eddy current probe through a connecting wire;

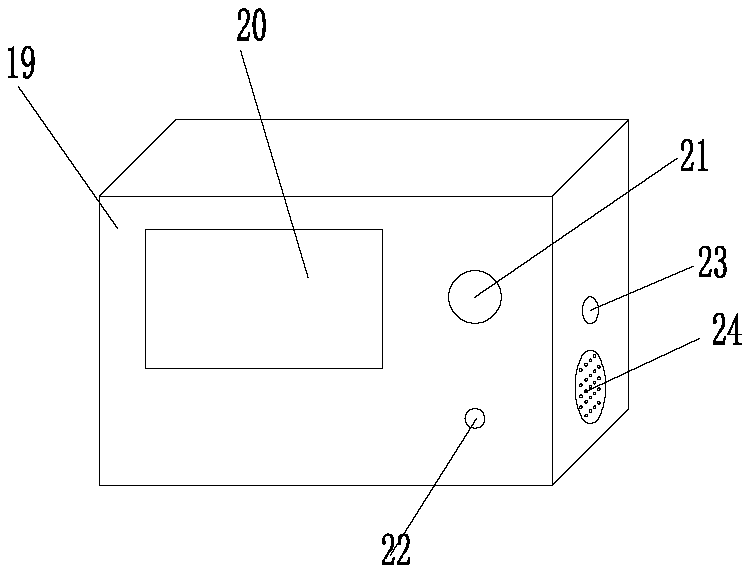

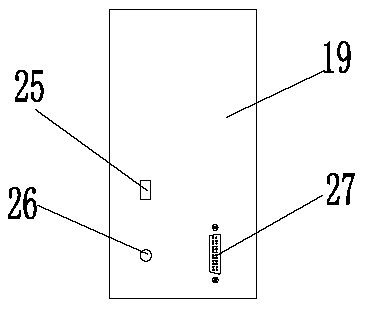

[0036]The eddy current detection host includes a host housing 19, on which a display 20 and a probe connection socket 24 are respectively installed, and a low-frequency oscillator, a lithium battery, a controller, an amplifier, a balance filter, a shifter, etc. are respectively installed in the housing 19. Phaser, gain adjustable amplifier and digital-to-analog converter, the output of the lithium battery is connected to the input of the low-frequency oscillator, the output of the low-frequency oscilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com