Gas turbine system performance prediction method based on key component failure model

A technology for gas turbines and prediction methods, which is applied in computing models, machine learning, special data processing applications, etc., can solve the problem that gray models cannot be used for long-term prediction, etc., and achieves the effect of high matching degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

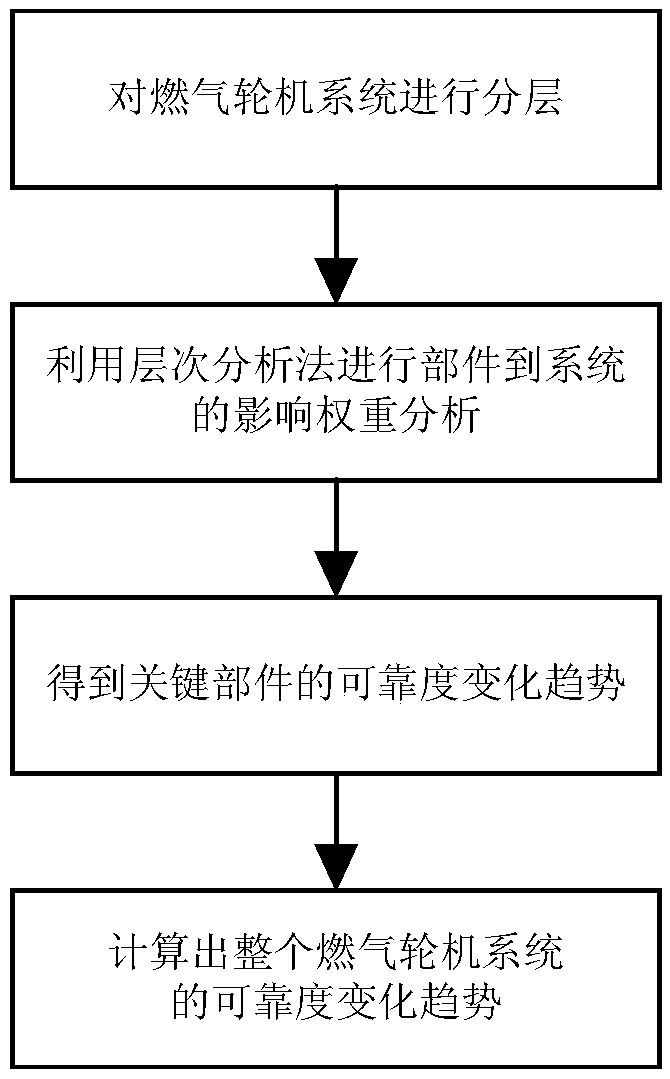

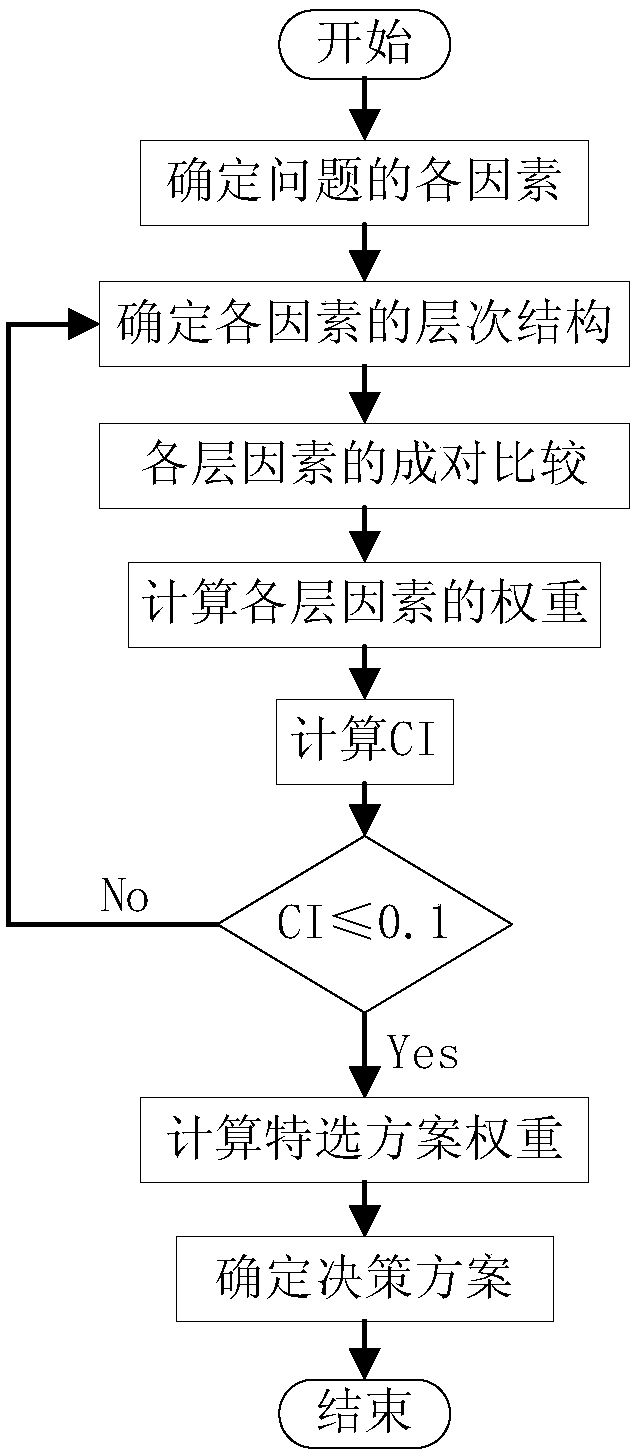

[0053] A specific embodiment of the present invention discloses a method for predicting the performance of a gas turbine system based on a key component failure model. The method utilizes the performance decline trend of key components of the gas turbine system to predict the overall performance decline trend of the gas turbine system, such as figure 1 shown, including the following steps:

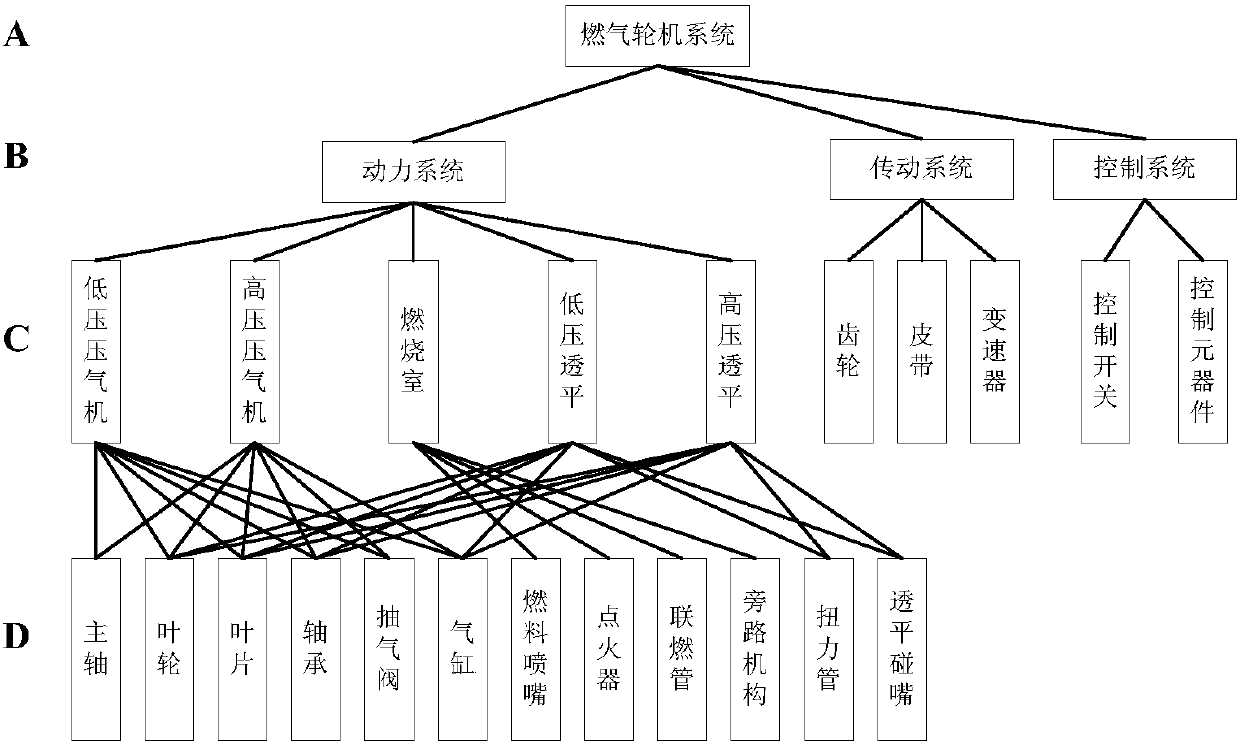

[0054] Step S1. Based on the structure and functional characteristics of the gas turbine system, perform a three-level decomposition of the gas turbine system, and decompose the gas turbine system into three levels: subsystems, key equipment, and key components

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com