Micro/nano optical 3D dynamic anti-fake film and manufacturing process

A production process and optical technology, applied in the field of anti-counterfeiting, to achieve the effect of enhancing the grade and added value of goods, good exposure effect, and effective anti-counterfeiting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

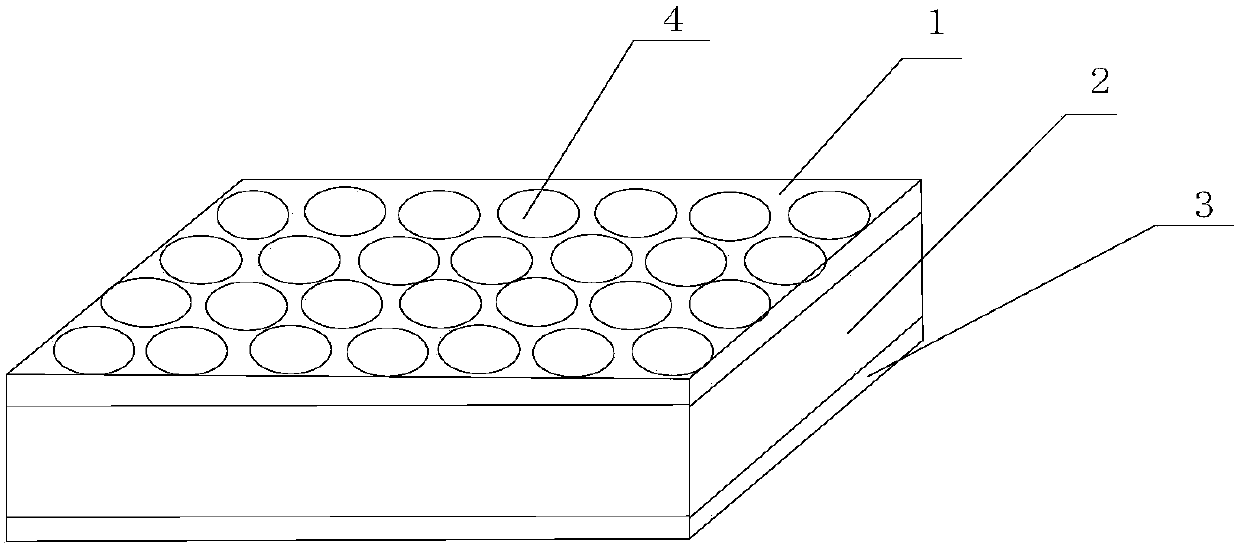

[0031] Such as figure 1 As shown, a micro-nano optical 3D dynamic anti-counterfeiting film of the present invention includes an image layer, an intermediate filling layer, and a microlens layer that are sequentially stacked from top to bottom. The intermediate filling layer is a transparent filling layer for adjusting the focal length, and the microlens A plurality of evenly distributed microlenses are arranged on the layer.

[0032] For the light wave emitted by the trademark on the image layer, it first passes through the transparent filling layer to adjust the focal length, then enters the microlens layer, and after focusing, imaging, adjusting and transforming the microlens layer, it is presented in the customer's field of vision. , the anti-counterfeiting label can obtain a three-dimensional and dynamic display effect that subverts the sensory perception of the human eye. It can be widely used in various daily products and financial and legal documents in various forms s...

Embodiment 2

[0034] This embodiment is preferably as follows on the basis of Embodiment 1: the distance between any two adjacent micro-lenses is in the range of 30 μm-1 mm. It is used to strengthen the diameter depth of the light wave emitted by the anti-counterfeiting label, enhance the dynamic effect, and attract customers' attention.

[0035] The aperture size of each microlens ranges from 10 μm to 100 μm. It is used to strengthen the diameter depth of the light wave emitted by the anti-counterfeiting label, enhance the dynamic effect, and attract customers' attention.

[0036] The middle filling layer is a transparent layer of PVC material. The transparent layer of PVC material is light, waterproof and moisture-proof, flame-retardant and heat-insulating, and can increase the service life of the anti-counterfeiting label.

[0037] The image layer is a transparent layer. The anti-counterfeiting label can better use the microlens layer for optical processing to achieve better optical e...

Embodiment 3

[0039] A manufacturing process of micro-nano optical 3D dynamic anti-counterfeiting film, comprising the following steps:

[0040] Step A) dividing the surface of the microlens array into a plurality of microlens units, and numbering each microlens unit one by one to form a plurality of microlens masks;

[0041] Step B) Process the surface of one or more microlens masks by laser direct writing according to the predetermined pattern to obtain the slit of the predetermined pattern;

[0042] Step C) each processed microlens mask is placed in an independent mobile device and each mobile device works independently, one or more processed microlens masks are placed in parallel on the photoresist surface, Under the action of a 300W-500W mercury lamp, move one processed microlens mask one by one through the photoresist surface for exposure, and then move the next processed microlens mask through the photoresist surface for exposure until The surface of the photoresist completes the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com