A cladding structure for a fusion reactor

A cladding and back plate technology, applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., can solve the problems of cumbersome installation procedures, high processing difficulty, and complicated cooling system design, so as to reduce installation procedures and improve cooling effect. , Easy to replace and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail now in conjunction with accompanying drawing.

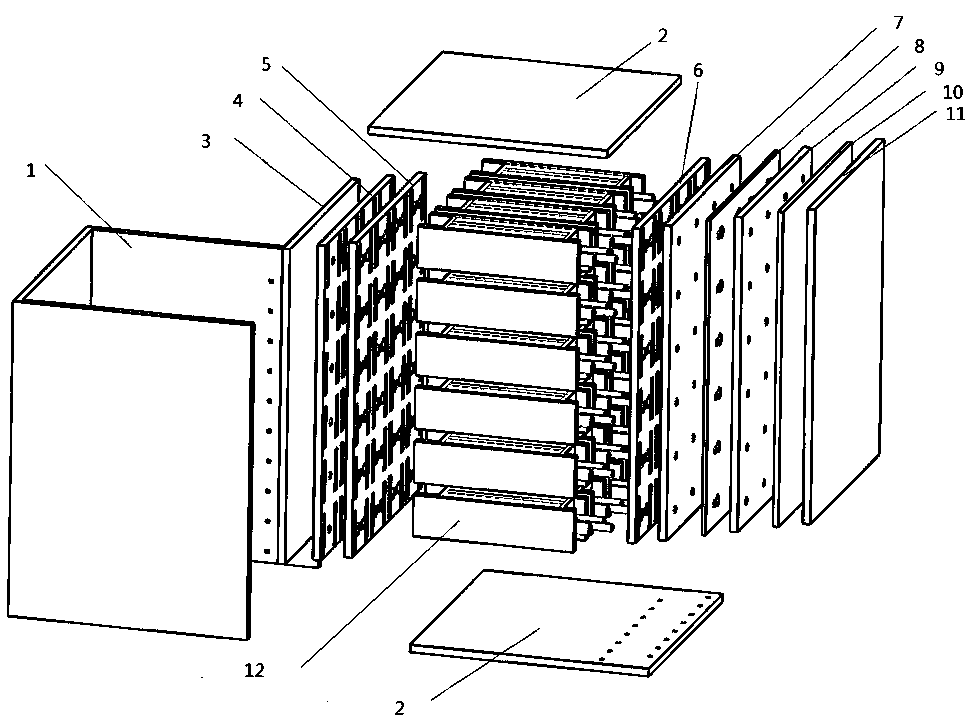

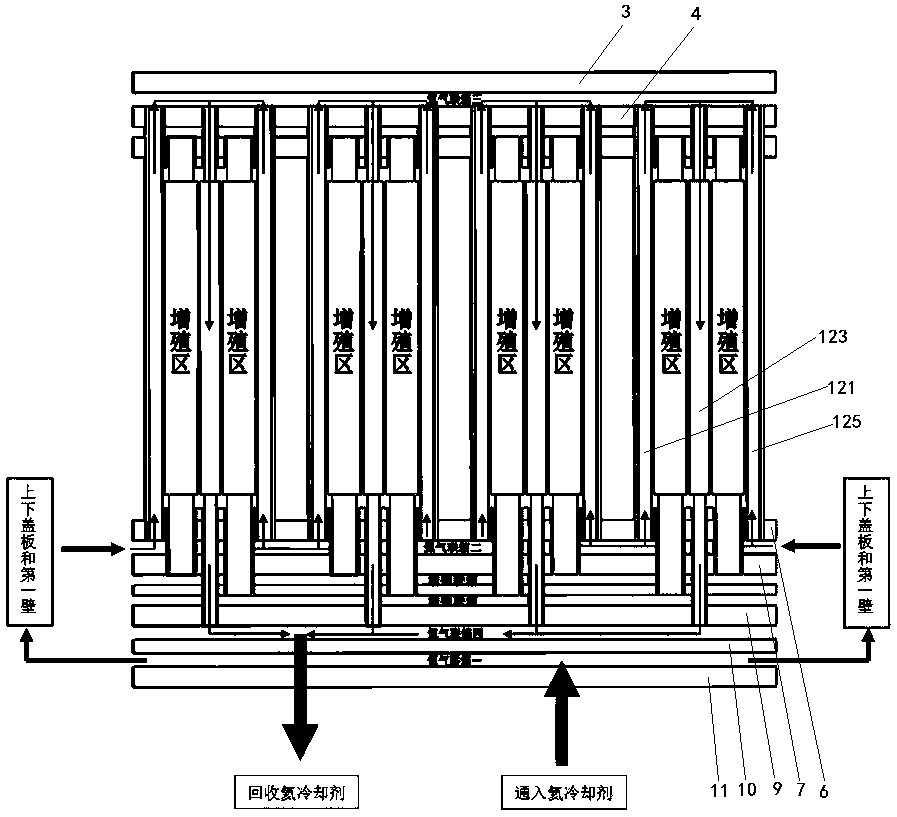

[0022] Such as figure 1 The shown cladding structure for a fusion reactor specifically includes a U-shaped first wall 1 , a cover plate 2 , a front back plate, a rear back plate and a multiplication unit 12 . The front backplane includes front backplane one 3, front backplane two 4, and front backplane three 5 arranged in sequence from front to back, and the backplane includes backback one 6, backplane two 7, Back panel three 8, back panel four 9, back panel five 10, back panel six 11.

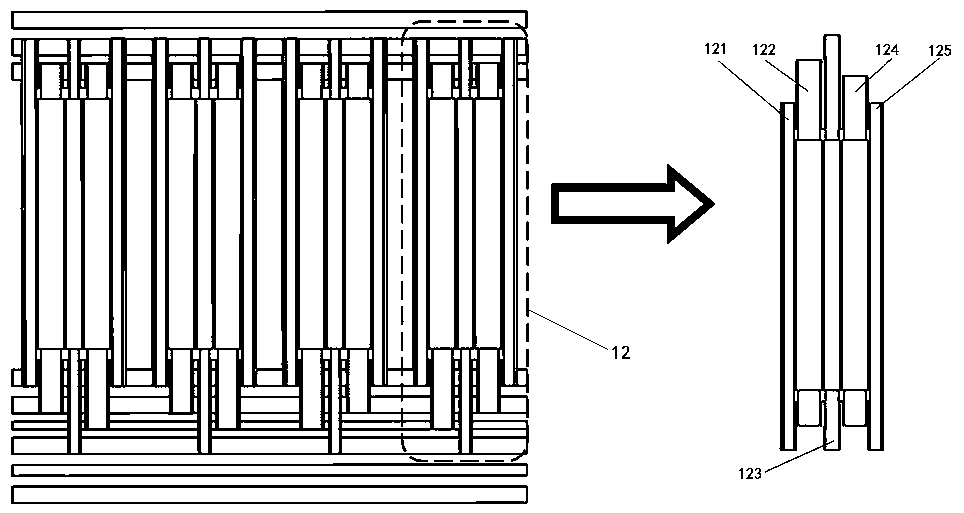

[0023] The number of multiplication units 12 is twenty-four, arranged according to 4×6. The front side of the multiplying unit 12 is sequentially inserted into the front backboard three 5, the front backboard two 4, and the front backboard one 3, and the rear side of the multiplication unit 12 is inserted into the backboard one 6, the backboard two 7, and the backboard one by one. Thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com