Laser processing system

A laser processing and processing technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low product quality and low processing efficiency, and achieve flexible production change, high refueling efficiency, and loading and unloading accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

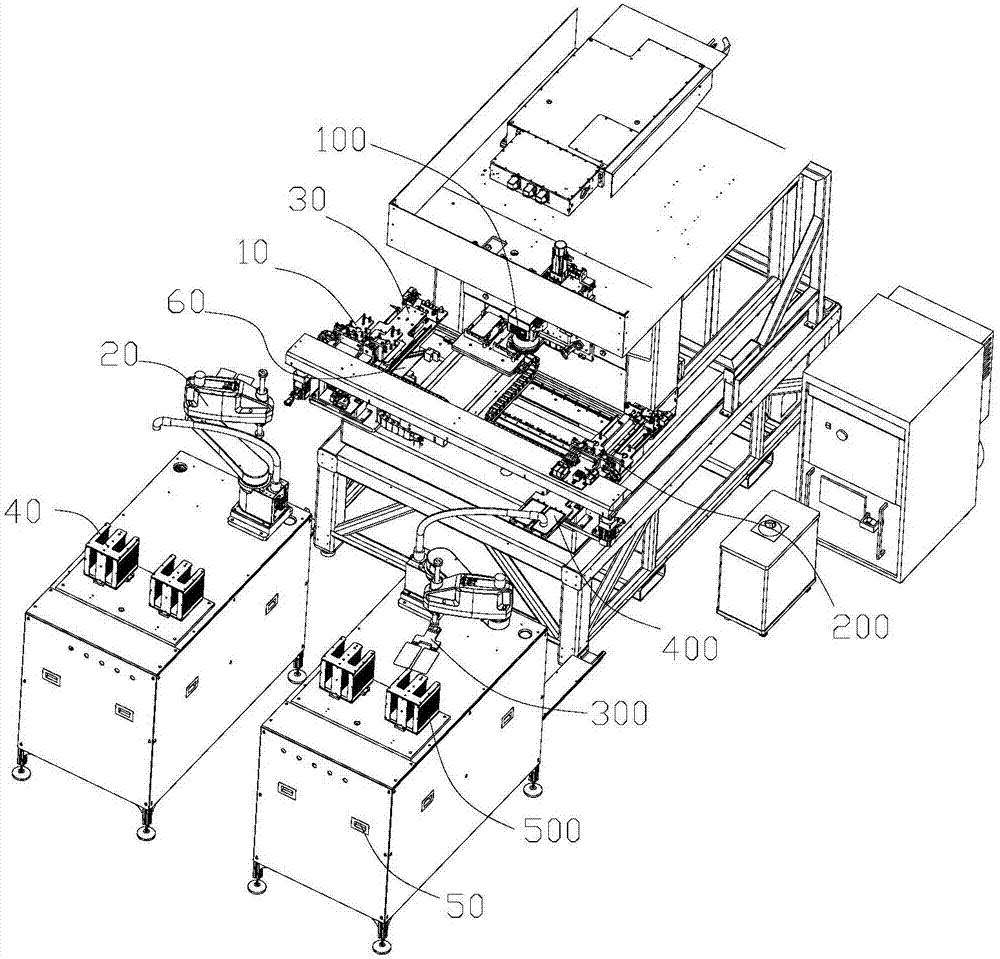

[0031] see figure 1 , this embodiment provides a laser processing system.

[0032] The laser processing system includes a laser processing unit 100, a blank transport unit, a finished product transport unit, a waste collection mechanism 60 and a code scanning mechanism 50. The blank transport unit is used to transport the blank to the position to be processed by the laser processing unit 100. The laser processing unit 100 Processes the blank located at the position to be processed to form a finished product, and the finished product transport unit is used to take away the finished product located at the position to be processed. In this embodiment, the blank transport unit automatically transports the blank to the position to be processed by the laser processing unit 100, the laser processing unit 100 processes the blank, and after the processing is completed, the finished product transport unit removes the finished product from the position to be processed , which is conveni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com