Kitchen oil separator tank with waste oil recycling function

A technology for grease traps and kitchens, applied in grease/oily substances/floating matter removal devices, liquid separation, separation methods, etc., can solve problems such as rapid water flow and unsatisfactory oil separation effect, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

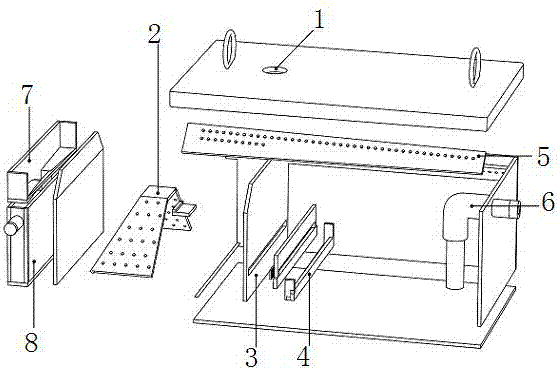

[0009] Such as figure 1 As shown, the kitchen grease trap that can recycle waste oil includes sewage inlet 1, slow flow baffle 2, partition 3, grille 4, oil collecting plate 5, outlet pipe 6, oil guide tank 7 and oil collecting box 8 , the slow flow baffle 2 is set at the lower part of the sewage inlet 1, the grille 4 is set at the bottom of the separator 3, the separator 3 is set at the bottom of the grease trap, the oil collecting plate 5 is set at the top of the grease trap, the outlet pipe 6 and the oil guide tank 7 are all arranged at the bottom of the grease trap, and the oil collection box 8 is arranged at the lower part of the oil guide tank 7. During operation, waste water enters the grease trap through the water inlet 1, and the speed of the water flow is slowed down by the slow flow baffle 2. After the water flow slows down , into the bottom of the primary grease trap, through the grille 4 at the bottom of the partition 3, into the secondary grease trap, the larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com