Composite multi-cylinder-linkage buffer and application thereof

A composite buffer technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as unreliable and effective buffering, and achieve excellent effects, high buffering efficiency, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

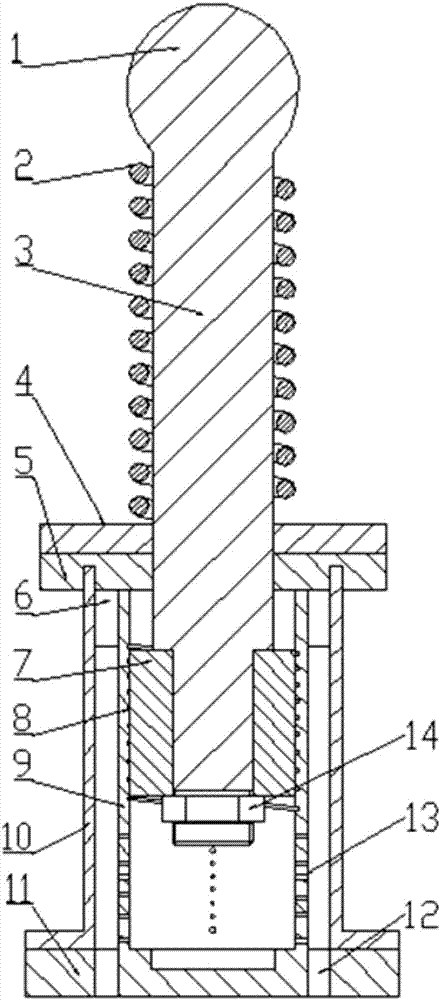

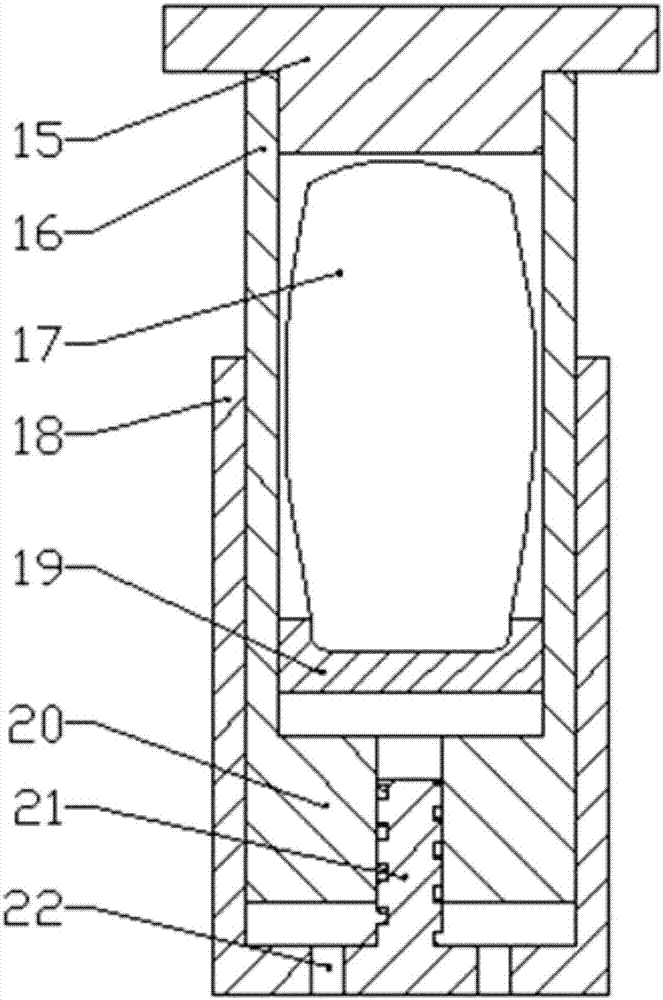

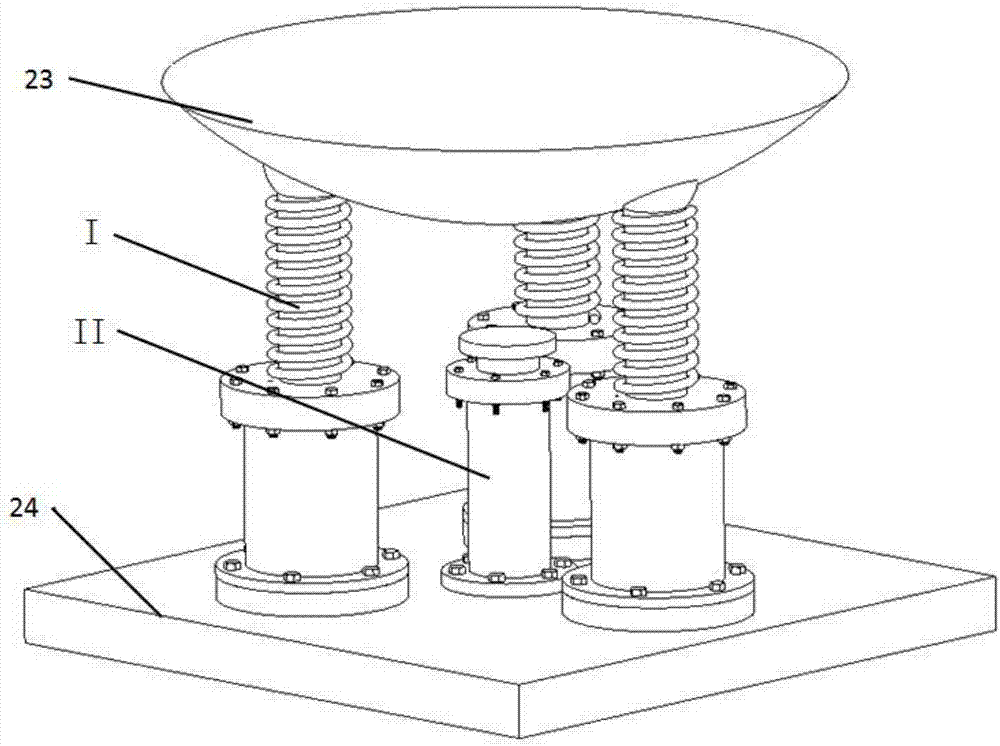

[0036] Such as Figure 1 to Figure 8 As shown, this embodiment provides a composite multi-cylinder linkage buffer, including a base plate 23 and a valve seat 24, and a liquid-pneumatic buffer II and three hydraulic buffers are arranged between the base plate 23 and the valve seat 24 Ⅰ. The bottom end of the hydraulic buffer is fixedly connected to the valve seat 24. The piston rod 3 of the hydraulic buffer is hinged to the bottom surface of the base plate 23. The bottom end of the hydraulic buffer is fixedly connected to the valve seat 24 and is connected to the hydraulic pressure Buffer connection; when the base plate 23 is impacted, multi-stage joint buffering is performed through the hydraulic buffer and the liquid-air buffer.

[0037] Wherein, the base plate 23 is a convex disc, the upper top surface of the convex disc is a circular plane, and the lower bottom surface is a hemispherical surface.

[0038] The hydraulic shock absorber includes an outer cylinder 10, a cylind...

Embodiment 2

[0043] A composite multi-cylinder linkage buffer, the structure of which is as described in Embodiment 1, the difference is that a pressure accumulating sponge 6 is arranged between the cylinder liner 9 and the outer cylinder 10 .

Embodiment 3

[0045] A method for using the composite multi-cylinder linkage buffer as described in Embodiment 2, the specific operation process is as follows:

[0046] When the base plate 23 is impacted by foreign objects, the base plate 23 compresses the piston rod 3 of the hydraulic shock absorber downward, and the piston rod 3 shrinks so that the oil in the rodless cavity of the cylinder sleeve 9 enters through the spiral groove 8 and the orifice 13 respectively. There is a rod cavity and a valve seat 24 oil circuit. When the oil pressure in the valve seat 24 oil circuit is too high, the first safety valve 25 is opened, and the oil enters the cylinder 18 of the liquid-gas buffer, and the liquid-gas buffer The piston rod 16 protrudes upwards; when the piston 7 of the hydraulic buffer enters the area of the orifice 13, the oil no longer enters the rod cavity, and the oil only enters through the orifice 13, the through hole 12, and the valve seat 24 Liquid-gas buffer until the bumper 15 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com