Photovoltaic assembly based on IBC battery packaging and manufacturing method

A photovoltaic module and battery technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems that the battery cannot use H-shaped welding, the reliability of single-sided welding is low, and the power of the module is high, so as to improve the photoelectric conversion efficiency and improve the front surface. The effect of small light receiving rate and module temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

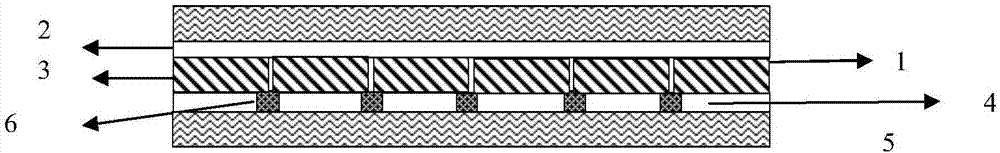

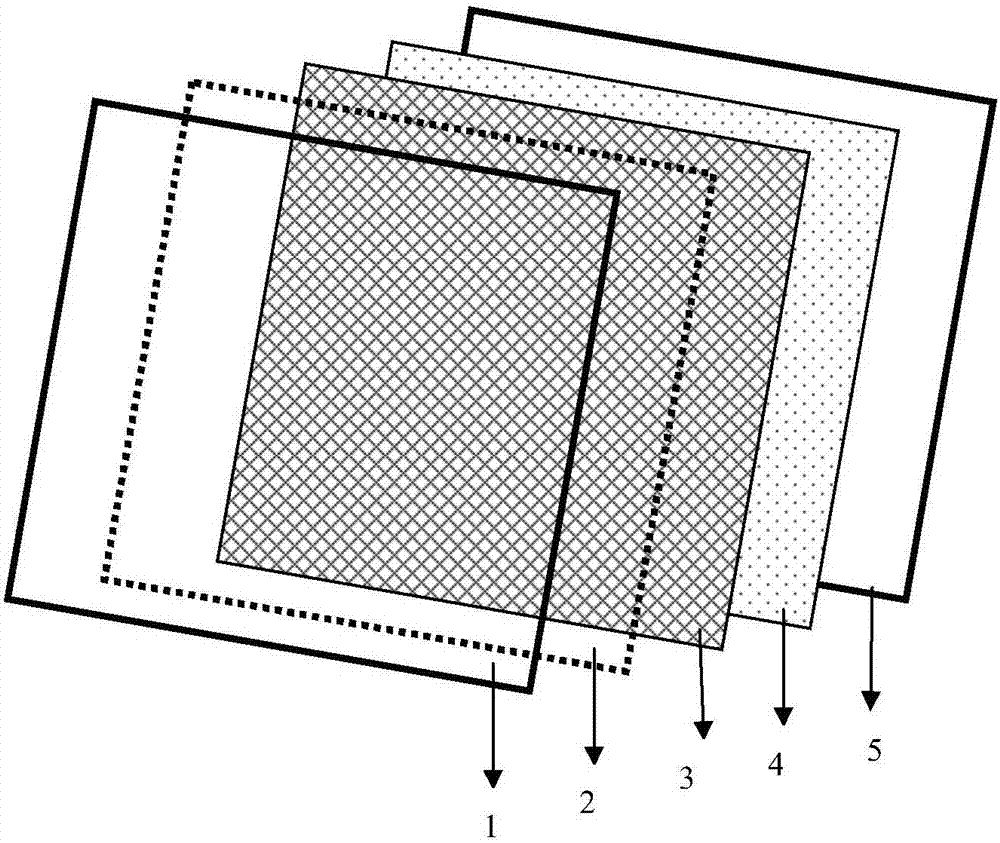

[0028] Example 1, such as figure 1 and 3 As shown, the photovoltaic module based on IBC cells includes a layer of tempered glass 1 , a first packaging material layer 2 , an IBC cell sheet layer 3 , a second packaging material layer 4 , a conductive adhesive, and a conductive backplane layer 5 stacked together in sequence.

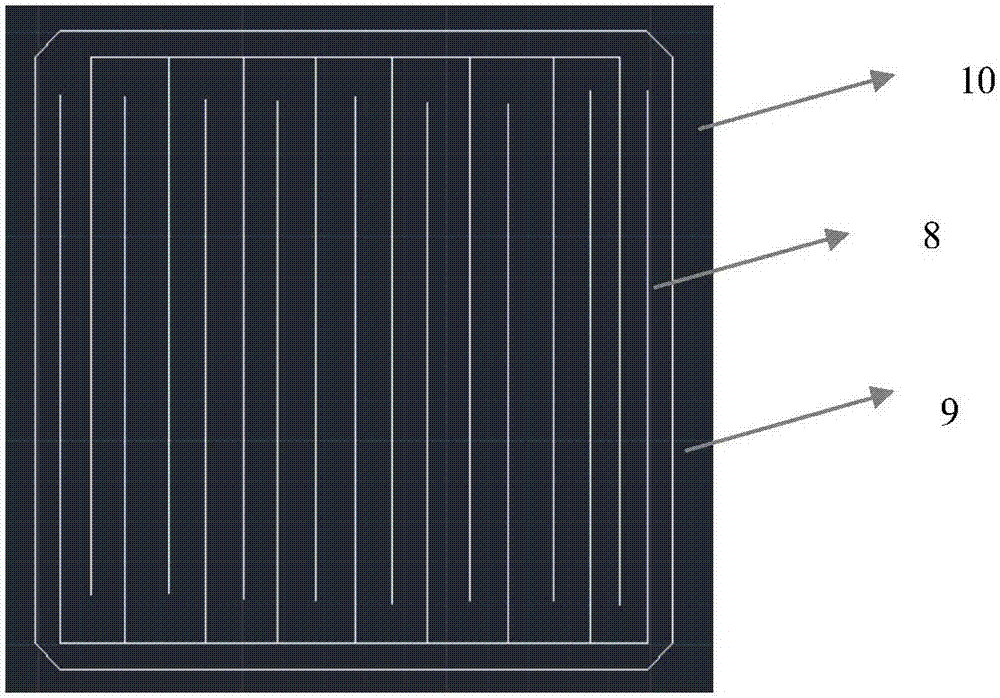

[0029] Several IBC cell sheets 10 form the IBC cell sheet layer 3, such as figure 2 As shown, the positive electrode 9 and the negative electrode 8 of the IBC battery sheet 10 are distributed across the back of the IBC battery sheet 10 .

[0030] The first packaging material layer 2 is arranged on the toughened glass layer 1 , and the IBC battery sheet layer 3 is arranged on the first packaging material layer 2 . The second packaging material layer 4 has a rectangular hole 6, the position of the rectangular hole 6 corresponds to the positive electrode 9 and the negative electrode 8 on the edge of the IBC battery sheet 10, and the position of the rectangu...

Embodiment 2

[0037] Embodiment 2, the manufacturing method of the above-mentioned photovoltaic module based on IBC battery, comprises the following steps:

[0038] Step 1: Select a piece of tempered glass with a thickness of 3.2mm for photovoltaic modules, lay the first encapsulation material layer 2POE on it, and place several 156*156mm IBC battery pieces 10 in sequence to form the IBC battery piece layer 3 .

[0039] Step 2: Cut a layer of second packaging material layer 4POE that is the same size as the tempered glass, and open a rectangular hole 6 on the layer of packaging material. The position of the rectangular hole 6 corresponds to the positive and negative electrodes on the side of the IBC battery sheet 10 , the rectangular hole 6 is 156mm long and 4mm wide, and the other electrode of the battery should not be exposed.

[0040] Step 3: Print conductive glue on the positive and negative electrodes of each battery side sheet 10 of the laid battery layer, that is, the exposed electro...

Embodiment 3

[0042]Example 3, select a piece of toughened glass with a thickness of 4mm, lay the first encapsulation material layer 2 pre-crosslinked EVA on it, and put in several 125*125mm IBC battery sheets 10 in turn to form an IBC battery sheet layer 3, and cut a layer The second packaging material layer 4 of tempered glass with the same size, and a rectangular hole 6 is opened on the layer of packaging material, and its position is consistent with the positive and negative electrodes on the side of the IBC battery sheet 10. Expose the other electrode of the battery, print conductive glue on the positive and negative electrodes of each battery side of the battery layer, that is, the electrode leaking from the corresponding rectangular hole, and then lay the second packaging material layer 4 with holes on several batteries, Make good contact with the conductive backplane. Then lay the conductive backplane, the conductive layer of the conductive backplane corresponds to the side electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com