Modularization power distribution automation terminal

A power distribution automation and modular technology, applied in the direction of electrical components, circuit devices, information technology support systems, etc., can solve the problems of inconsistent interfaces, limited flexibility, and inability to ensure clock synchronization of functional modules, etc., to achieve convenient maintenance, The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

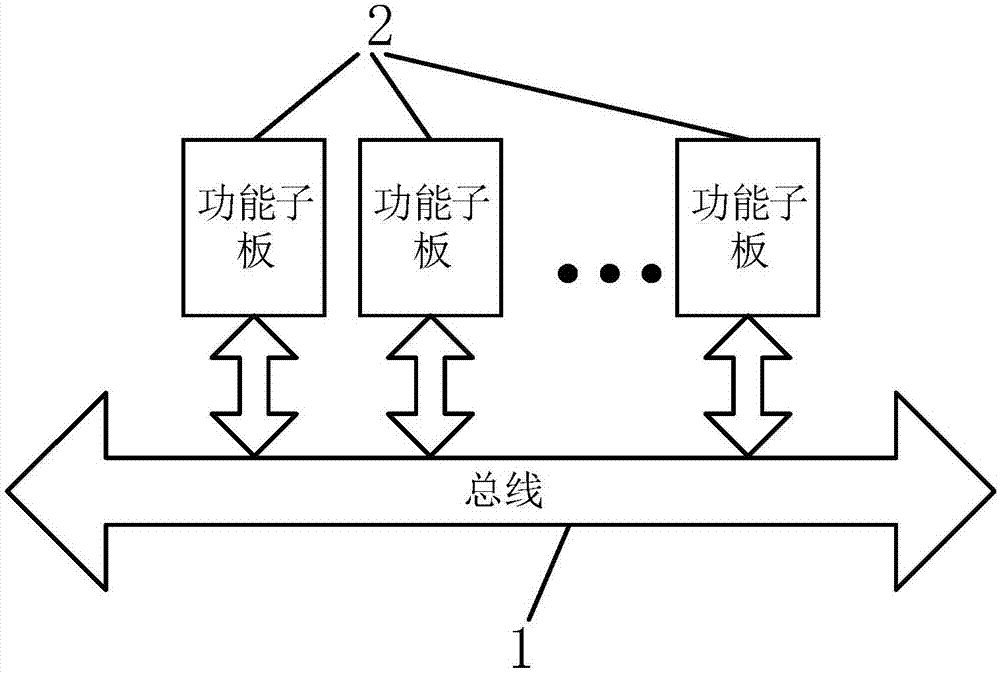

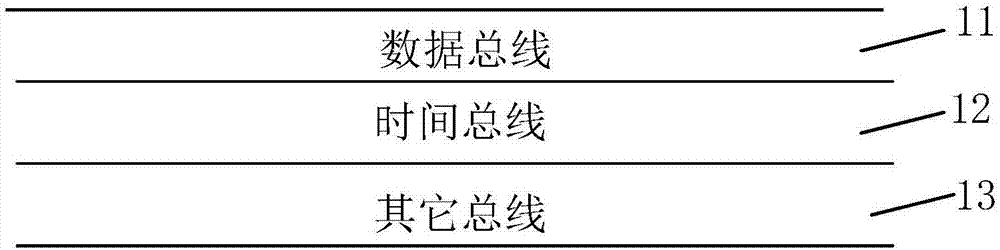

[0024] Such as figure 1 As shown, a modular power distribution automation terminal includes a bus board 1 and a functional sub-board 2, the bus board 1 is provided with multiple bus board interfaces, the functional sub-board 2 is a modular terminal, and each functional sub-board 2 functions It is independent, for example, it can be a current acquisition sub-board, a voltage acquisition sub-board, etc. Each functional sub-board 2 is equipped with a sub-board interface that matches the interface of the bus board, and the functional sub-board 2 is matched with any bus board interface. .

[0025] The sizes and shapes of all bus board interfaces on the bus board 1 are consistent, and the pin distribution and pin function definitions of all bus board interfaces on the bus board 1 are consistent. Bus board interfaces and daughter board interfaces include, but are not limited to, digital interfaces. One or more functional sub-boards 2 are configured. As an independent module, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com