Silicone rubber with low modulus and high tear strength and method for preparing silicone rubber

A technology of high tear strength and silicone rubber, applied in low modulus high tear strength silicone rubber and its preparation, silicone rubber and its preparation field, can solve the problems of high modulus of silicone rubber and can not meet the use requirements, and achieve High tear strength, enhanced ability to resist external force, low elastic modulus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

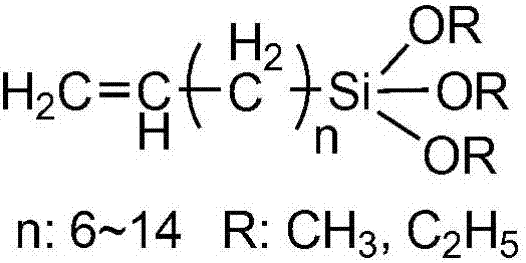

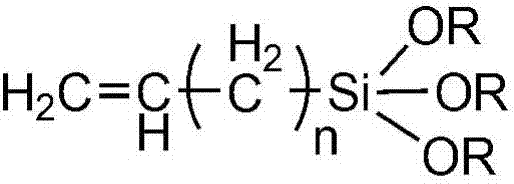

Method used

Image

Examples

Embodiment 1

[0039] 70 parts of methyl vinyl silicone rubber A (vinyl content 0.04%, molecular weight 500,000), 30 parts of methyl vinyl silicone rubber B (0.15%, molecular weight 650,000), 3 parts of hydroxyl silicone oil (viscosity 40mPa.s) , 20 parts of fumed white carbon black (specific surface area 380m 2 / g), 0.5 parts of silane coupling agent, kneaded into a dough in a kneader, and then vacuumed for 2 hours (vacuum-0.08MPa, temperature 120°C). Cool the kneaded silicone rubber to room temperature and let it stand for 24 hours.

[0040] Add 1.5 parts of benzoyl peroxide to the open mill, pass it 6 times, cool the rubber to room temperature, and let it stand for more than 16 hours; then vulcanize it with a flat vulcanizer, the conditions are as follows: temperature 160 ° C, pressure 15 MPa, time 10 minute.

Embodiment 2

[0042] 80 parts of methyl vinyl silicone rubber A (vinyl content 0.15%, molecular weight 650,000), 20 parts of methyl vinyl silicone rubber B (5%, molecular weight 350,000), 5 parts of diphenylsilanediol, gas phase French silica 25 parts (specific surface area 200m 2 / g), 1.0 parts of silane coupling agent, kneaded in a kneader to form a dough, and then vacuumed for 2 hours (vacuum-0.08MPa, temperature 150°C). Cool the kneaded silicone rubber to room temperature and let it stand for 24 hours.

[0043] Add 1.5 parts of benzoyl peroxide to the open mill, pass it 6 times, cool the rubber to room temperature, and let it stand for more than 16 hours; then vulcanize it with a flat vulcanizer, the conditions are as follows: temperature 160 ° C, pressure 15 MPa, time 10 minute.

Embodiment 3

[0045] 90 parts of methyl vinyl silicone rubber A (vinyl content 0.04%, molecular weight 650,000), 10 parts of methyl vinyl silicone rubber B (5%, molecular weight 600,000), 5 parts of hydroxyl silicone oil (viscosity 30mPa.s) , 30 parts of fumed silica (specific surface area 150m 2 / g), 1.5 parts of silane coupling agent, kneaded in a kneader to form a mass, and then vacuumed for 2 hours (vacuum-0.08MPa, temperature 150°C). Cool the kneaded silicone rubber to room temperature and let it stand for 24 hours.

[0046] Add 0.5 parts of 2,4-dichlorobenzoyl peroxide (double 2,4) to the open mill, pass it 6 times, cool the rubber to room temperature, and place it for more than 16 hours; then vulcanize it with a flat vulcanizer, and The conditions are as follows: temperature 160° C., pressure 15 MPa, and time 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com