Method for improving extraction effect of single coal seam with high gas and low permeability

A low-permeability and gas technology, used in earth-moving drilling, surveying, wellbore/well components, etc., can solve the problems of complex geological conditions, unsuitable arrangement of penetration enhancement and extraction, unclear in-situ stress state, etc. Uncertainty, the effect of good development and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

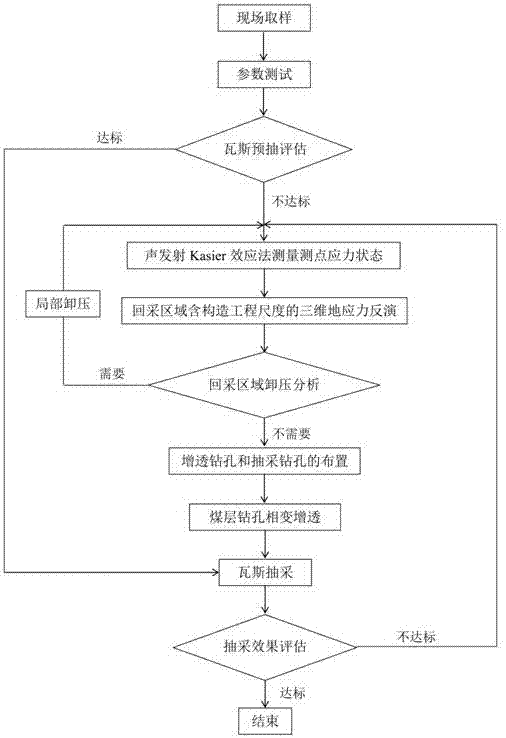

[0024] Such as figure 1 As shown, a method for improving the extraction effect of a single coal seam with high gas and low permeability, the specific method implementation steps are:

[0025] 101 ~ Drilling samples in the recovery area, testing the physical parameters of the coal body, including strength, gas content, adsorption constant, permeability coefficient and attenuation coefficient.

[0026] 102~Test the physical properties and fragmentation of the roof and floor of the coal seam. The multi-point fine AE method is used to test the stress state of the coal seam and the roof and floor, the magnitude and direction of the maximum horizontal principal stress, the minimum horizontal principal stress and the vertical stress.

[0027] 103 ~ Gas pre-drainage evaluation: whether the effect of the pre-drainage area meets the "Basic Indicators for Gas Drainage in Coal Mine".

[0028] 104~Acoustic emission Kaiser effect experiment; X, Y, Z, X45 of different measuring points o Y,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com