Device for preventing gas entrapment in core inserting and propellant casting processes of solid rocket engine

A technology of solid rockets and engines, which is applied in the direction of rocket motor devices, jet propulsion devices, machines/engines, etc., can solve the problems that the ferrule cannot guarantee uniform quality, complex supporting equipment, and cannot effectively prevent air inclusions, etc., to achieve improved Ferrule efficiency, guaranteed ferrule quality, and easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

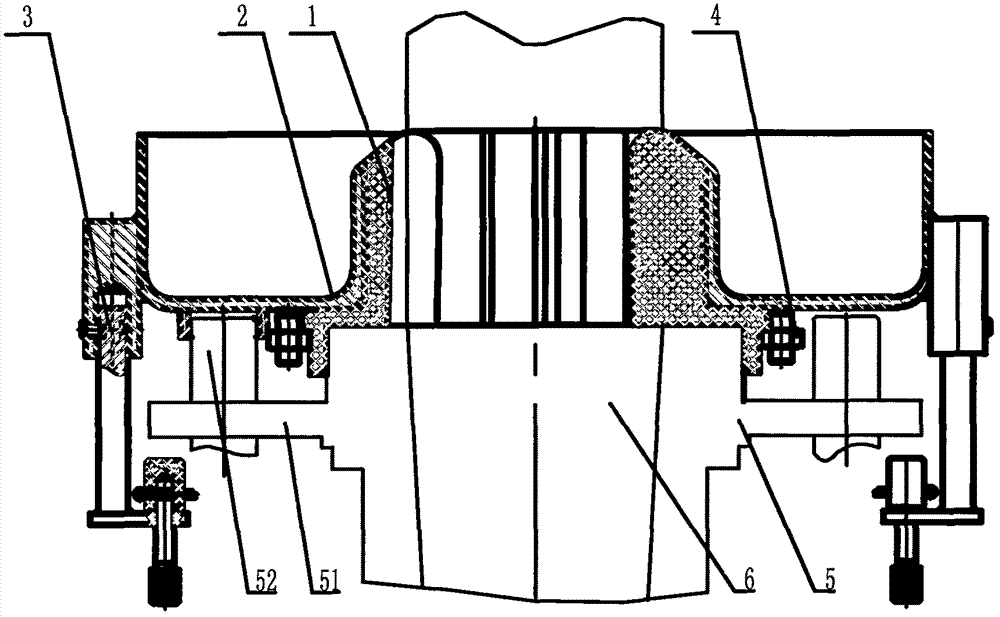

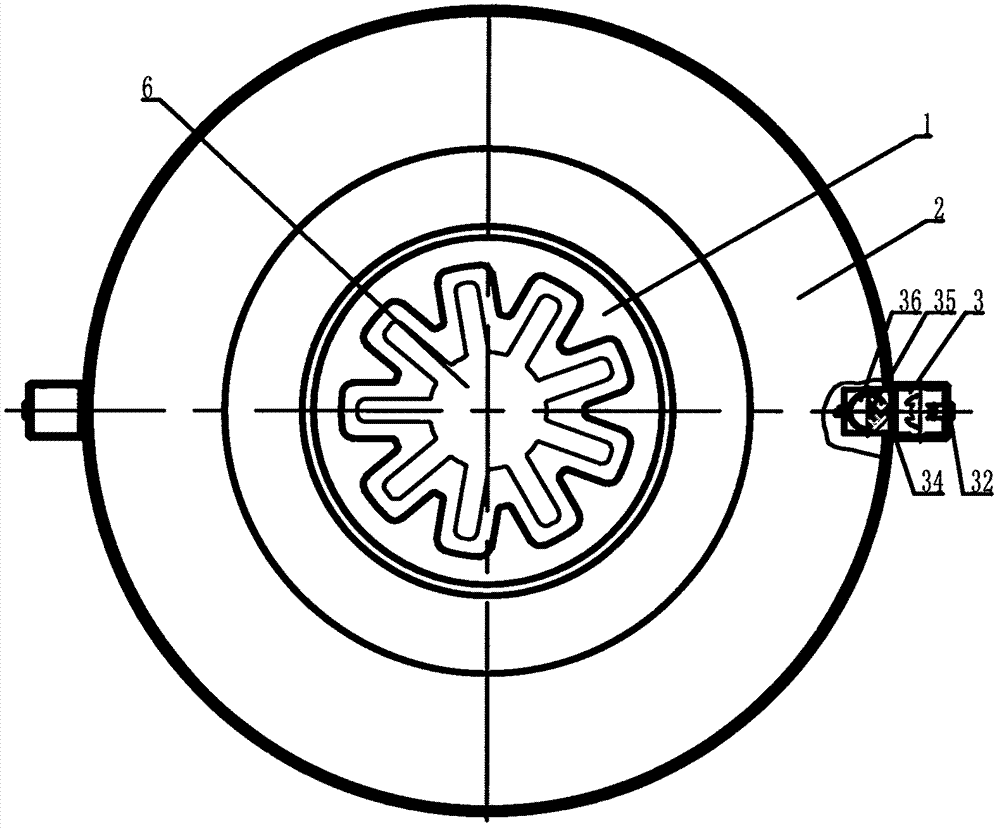

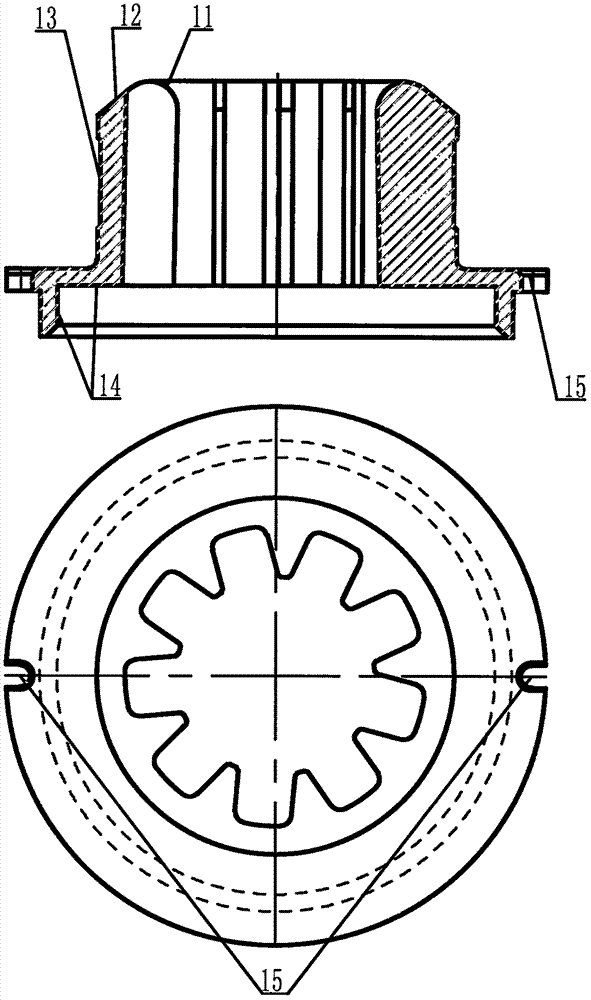

[0019] Refer to attached Figure 1-5 , The main structure of the solid rocket motor core casting press plate and material receiving device of the present invention includes: airfoil press plate 1, material receiving tray 2, and steering arm assembly 3.

[0020] The airfoil pressure plate 1 is fixed at the pouring port 5 of the engine to replace the function of manual pressing; the material receiving tray 2 is installed on the outside of the airfoil pressure plate 1 to cooperate with the pressure plate with a small gap, and is fixedly connected with the nut 4 to hold the overflowing propulsion agent; the steering arm assembly is 180 ° phase vertical and evenly distributed on the outer surface of the welded tray 2, and its function is to hold the pressing plate and the receiving device against the engine sprue at 5 places.

[0021] Further, the airfoil pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com