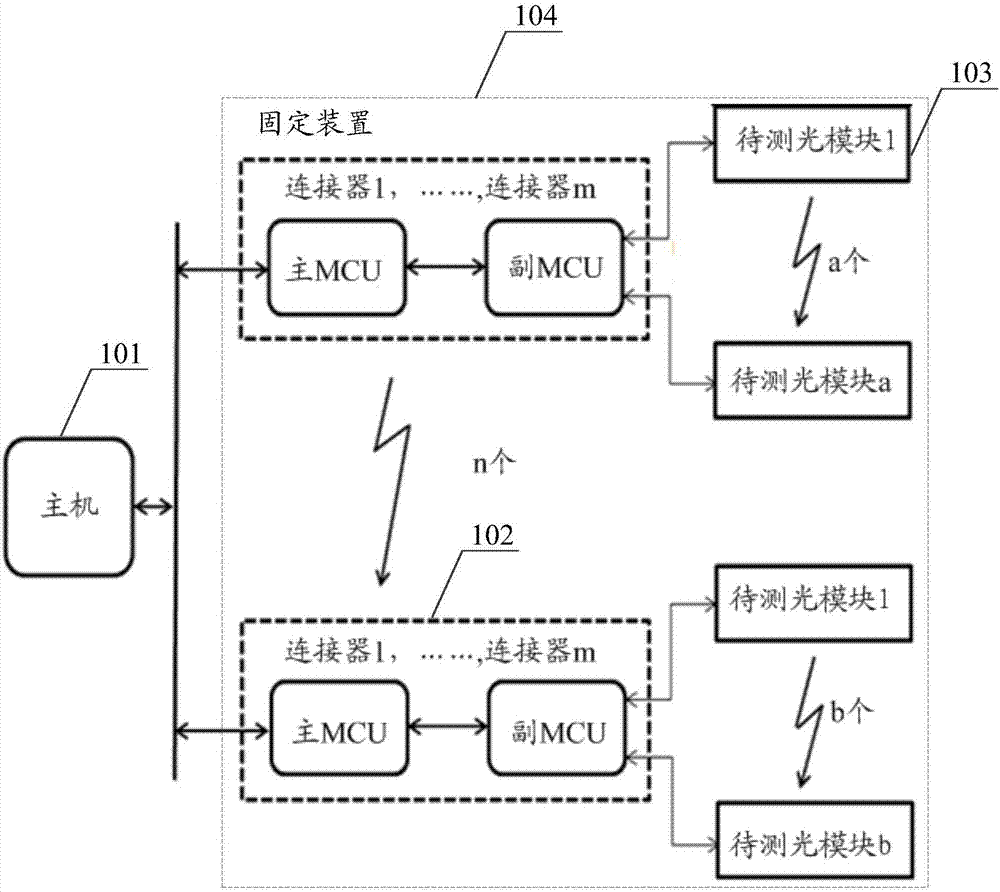

Optical module and optical device state monitoring system

A state monitoring and optical device technology, applied in optical instrument testing, machine/structural component testing, instruments, etc., can solve the problems of high cost, long query or scanning time, low communication rate, etc., to achieve fast communication speed, reduce Cost, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

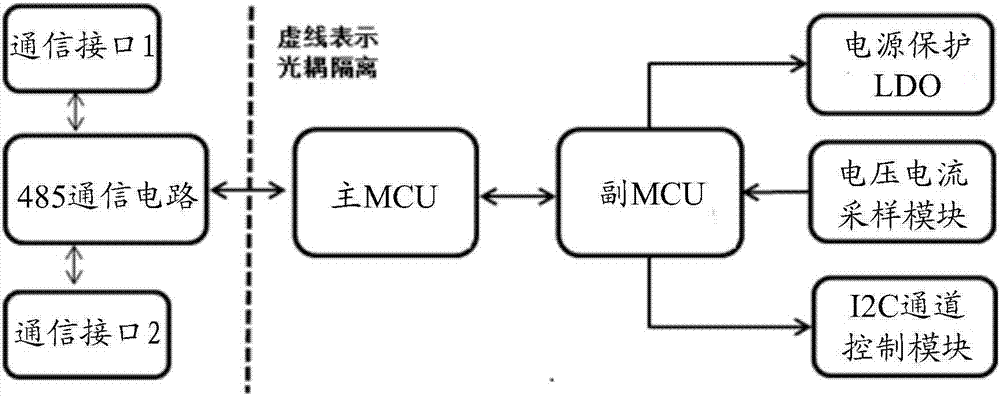

[0046] In a specific implementation manner, the circuit block diagram of the test board 102 is as follows figure 2 As shown, each test board uses a 485 communication circuit, including a main MCU, a sub-MCU, two RJ45 communication interfaces with electrical isolation, power supply protection low dropout linear regulator (power supply protection LDO), voltage and current sampling module, I2C Channel control module, Pin1 and 2 are Vcc+5V, Pin2 and 3 are A+, Pin4 and 5 are B-, Pin7 and 8 are ground. The main MCU and the sub-MCU use the I2C communication mechanism. The communication interface is a twisted pair insertion interface inside the network. The main / sub-MCU will monitor the working current of the modules on the test board in real time. The monitoring circuit can use high-precision sampling resistors and amplifiers to realize small current monitoring and stable monitoring data. The monitoring circuit is simple to implement and low in price, which greatly reduces the over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com