Shear press apparatus for masonry and method for testing shear press combined strength of masonry

A strength test, masonry technology, applied in the direction of using a stable shear force to test the strength of materials, can solve the problems of overestimating the ultimate shear strength of masonry, difficult to test the shear and compressive strength of masonry, etc. Loading costs, the effect of simplifying the loading process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

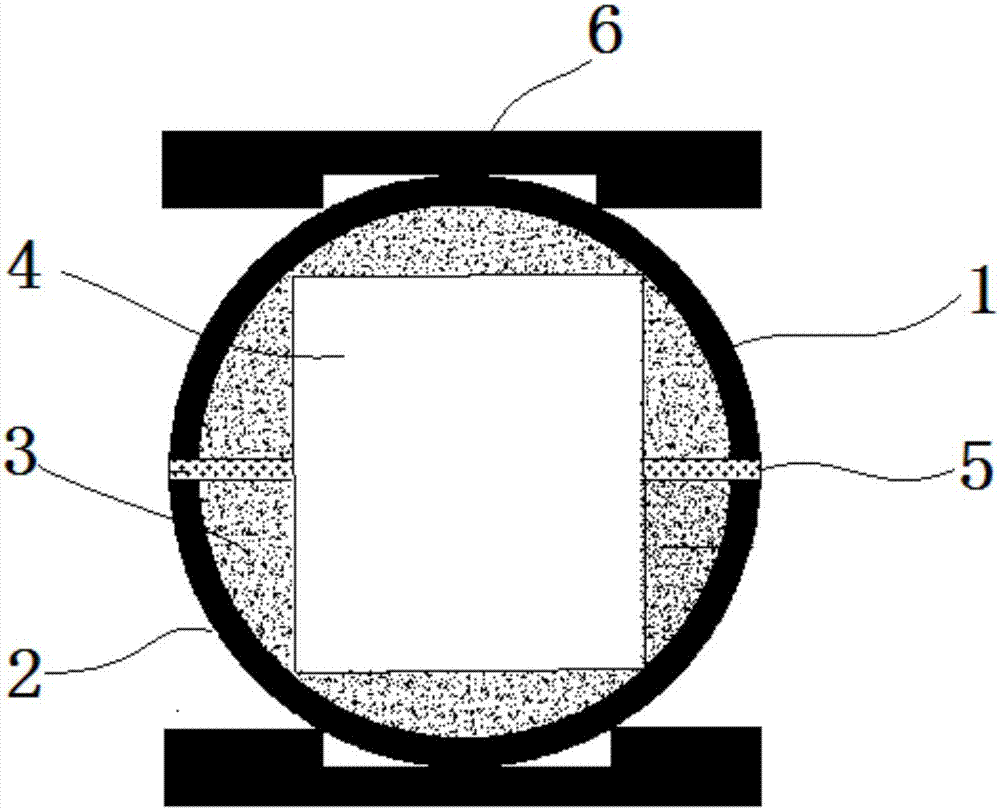

[0032] Such as figure 1 As shown, the device for testing the masonry shear compressive strength of this embodiment includes two molds (1, 2), both of which are provided with curved surfaces and axial planes, wherein the curved surfaces are cylindrical curved surfaces, and the axial plane is provided with There are masonry placement slots 4.

[0033] In some specific embodiments, the two molds are curved cylinders, the outer surface of the curved cylinder is a curved surface, the cylinder is filled with bonding material 3, the external surface of the bonding material is an axial plane, and There is a masonry placement slot. In the case of testing rectangular masonry, such as brick masonry, the curved cylinder in this embodiment is a semi-cylindrical cylinder, and the masonry placement groove is rectangular. The bonding body material may be high-strength compression-resistant materials such as concrete, steel, and wood.

[0034] In some occasions, two molds are assembled into...

Embodiment 2

[0038] The method that adopts the device test masonry shear compressive strength in the above-mentioned embodiment comprises

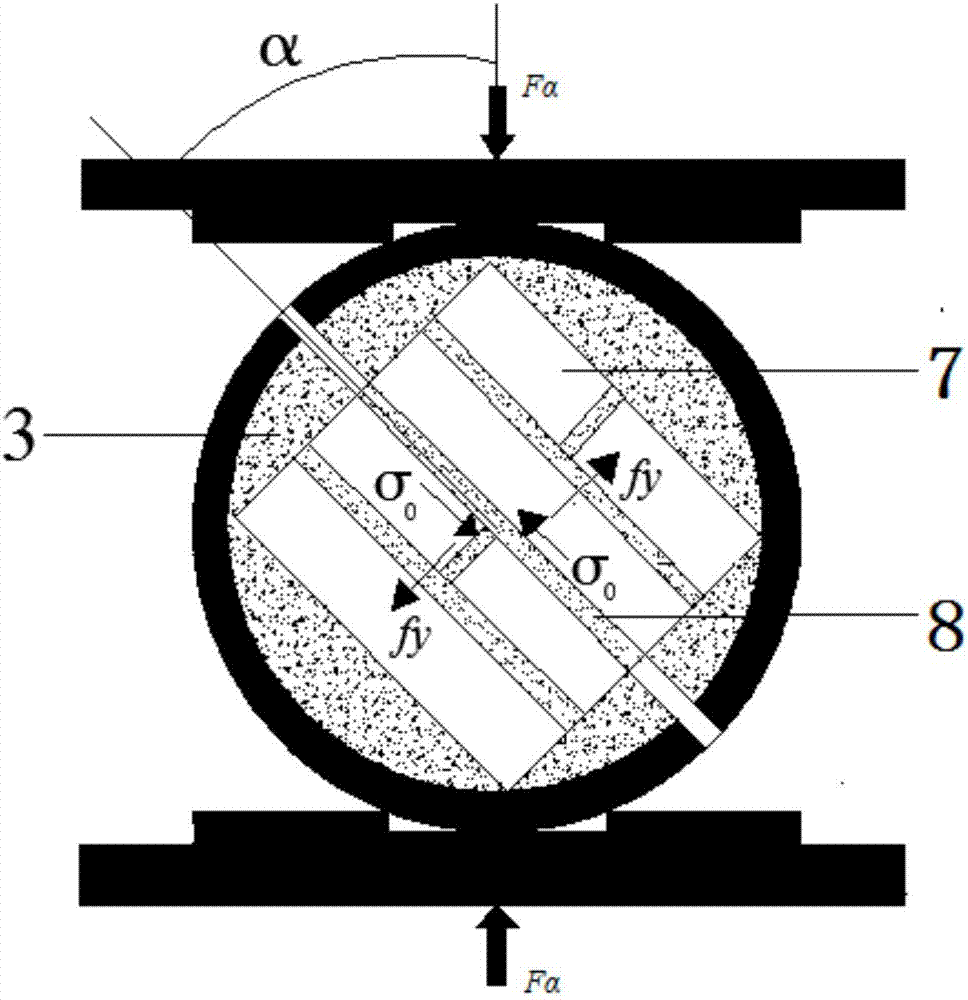

[0039] Step one, such as figure 2 As shown, the masonry 7 to be tested is installed in the two masonry placement grooves described in the above-mentioned embodiments and assembled into a test piece. The gap 5 of is located on the same straight line;

[0040] Step 2, apply pressure F on the curved surfaces of the two molds 0° , the F 0° The initial direction of is located on the horizontal gray joint to be measured;

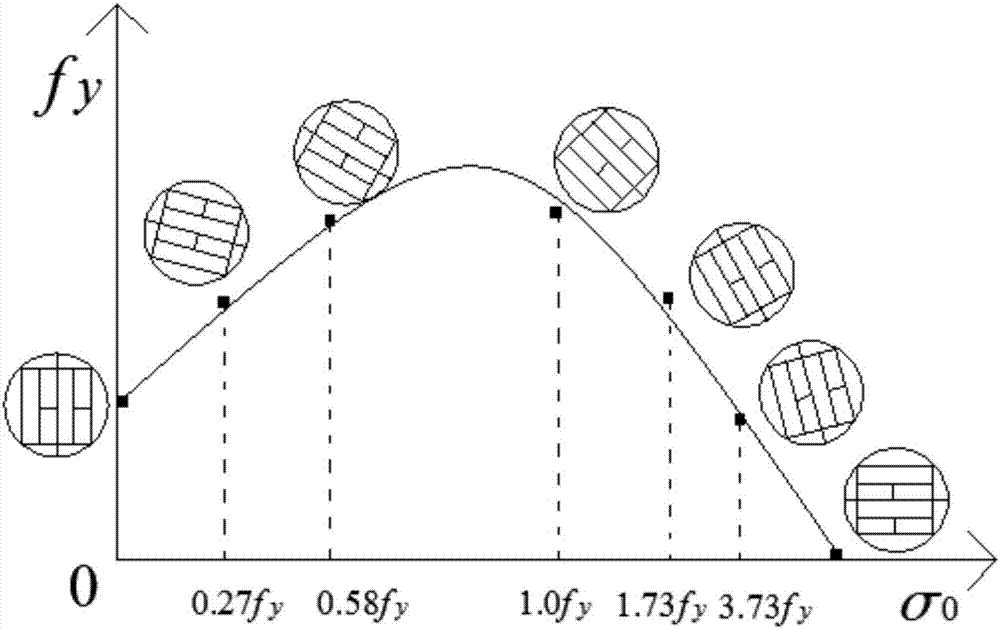

[0041] Step 3, then rotate the test piece several times, respectively measure the uniaxial vertical pressure Fα at each rotation angle, calculate the normal stress and shear stress, and α is the rotation angle.

[0042] In the general test process, the angle of each rotation in step 3 is the same, and each rotation is 10°-20°.

[0043] When concrete is used as the bonding material, the method for making the test specimen in step 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com