Testing method for the effect of aluminum-plastic film encapsulation

A detection method and technology of aluminum-plastic film, which are applied in measuring devices, mechanical devices, instruments, etc., to achieve the effects of high controllability, simple implementation process, and elimination of missed inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

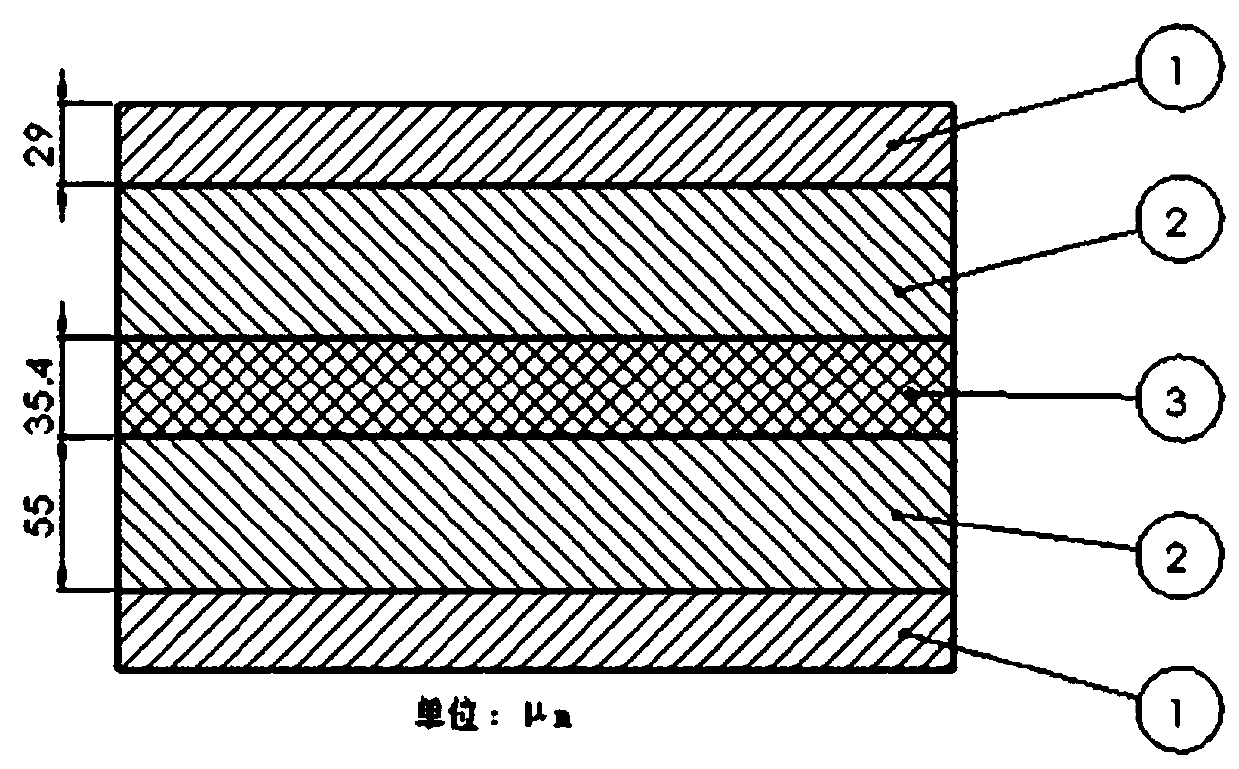

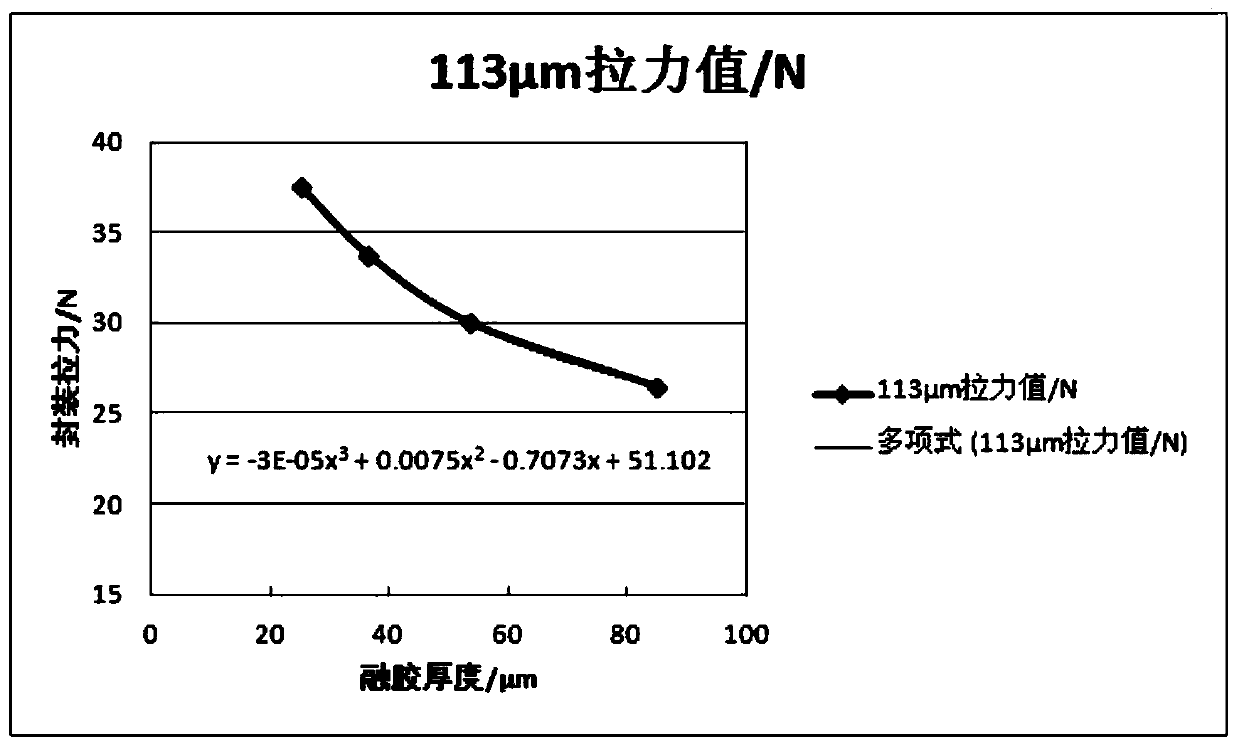

[0046] like figure 1 , image 3 As shown, a 113μm aluminum-plastic film packaging effect detection method, the steps are as follows:

[0047] (1) Preparation of measurement samples: Cut the 113 μm aluminum-plastic case plastic-sealed by pressurized hot-melt method longitudinally at a position 3 mm away from the battery body along the melting direction with a phase cutting knife. Then the cut sample is clamped with a 1mm thick PP board, and the fixed sample is first cut 10 times with a thickness of 50 μm on a flat push microtome, and then cut 10 times with a thickness of 10 μm. A sample with a smooth upper surface was obtained.

[0048] (2) Sample measurement: put the prepared sample under a high-magnification image measuring instrument to observe and measure with a magnification of 500 times. Use the ruler on the equipment to measure the thickness of the melted glue.

[0049] (3) Establish a standard expression: different melt thicknesses are obtained by changing the packa...

Embodiment 2

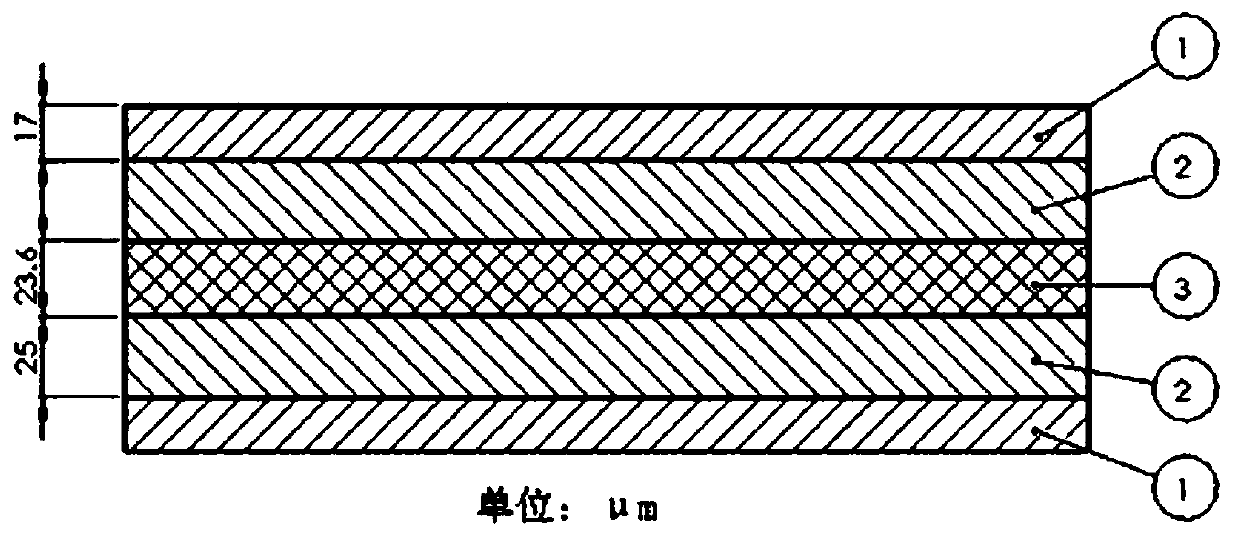

[0055] like figure 2 , Figure 4 As shown, a 67μm aluminum-plastic film packaging effect detection method, the steps are as follows:

[0056] (1) Preparation of measurement samples: Cut the 67 μm aluminum-plastic case plastic-sealed by pressurized hot-melt method longitudinally at a position 4 mm away from the battery body along the melting direction with a phase cutting knife. Then the cut sample is clamped with a 1mm thick PP board, and the fixed sample is first cut 10 times with a thickness of 50 μm on a flat push microtome, and then cut 10 times with a thickness of 10 μm. A sample with a smooth upper surface was obtained.

[0057] (2) Sample measurement: put the prepared sample under a high-magnification image measuring instrument to observe and measure with a magnification of 750 times. Use the ruler on the equipment to measure the thickness of the melted glue.

[0058] (3) Establish a standard expression: different melt thicknesses are obtained by changing the packa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com