Structure for heat radiation of battery module and installation and fixation of electrical cores

A battery module and fixed structure technology, applied in battery pack components, secondary batteries, structural parts, etc., can solve the problems of large volume, high energy consumption and high cost of the support frame, improve heat dissipation efficiency, and ensure reliability. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

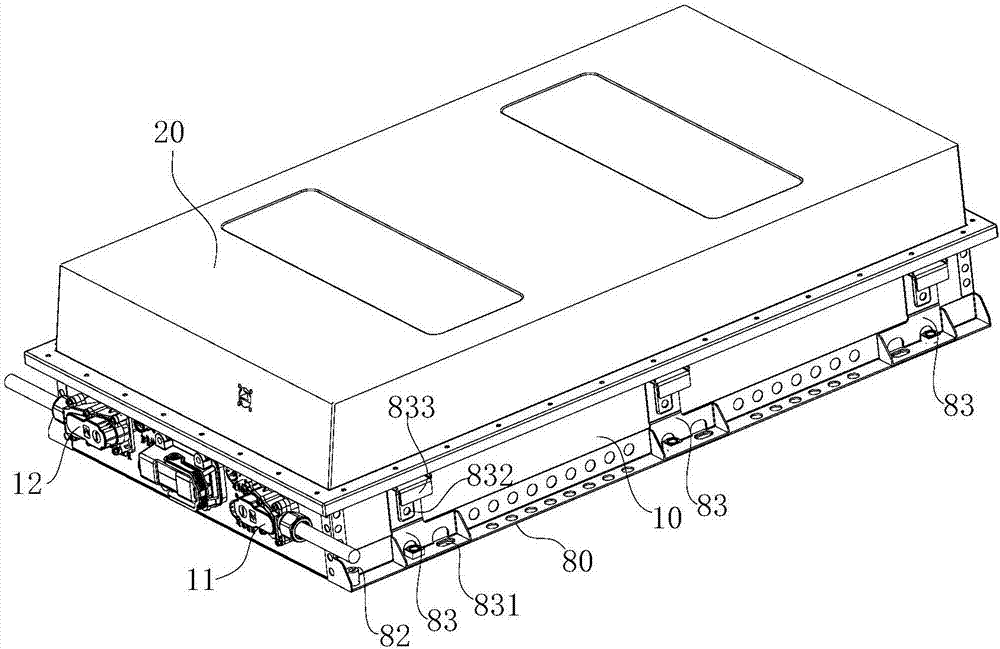

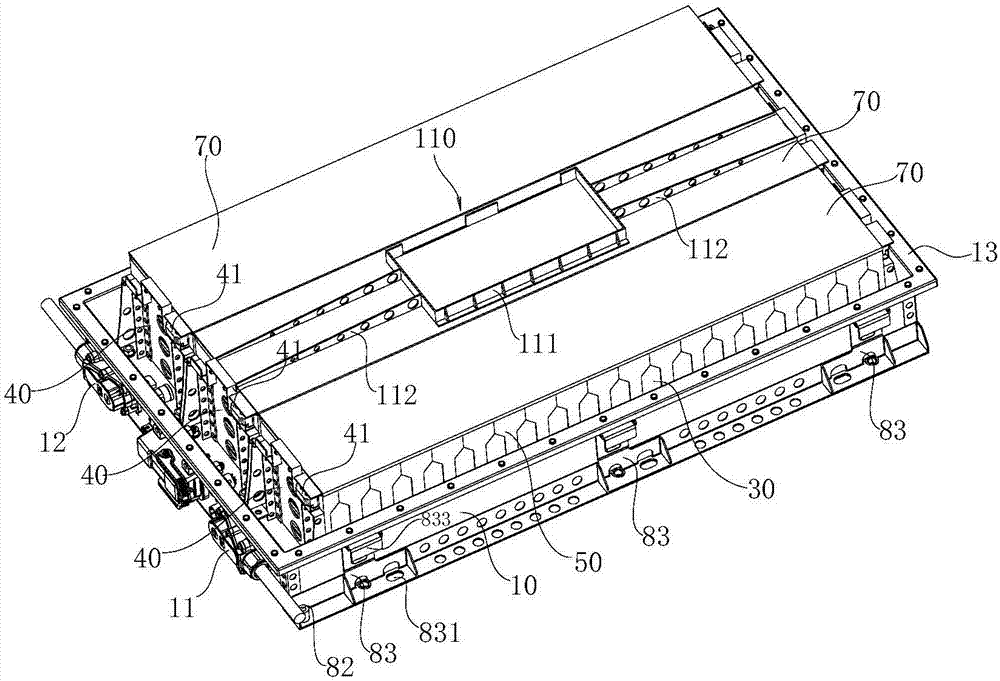

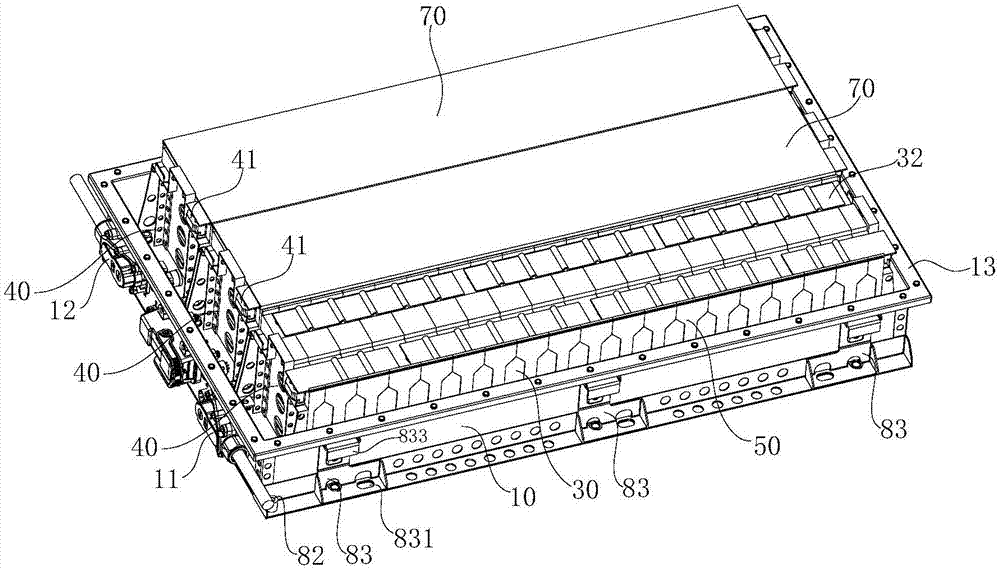

[0026] combine Figure 1 to Figure 12 , the present invention is further described:

[0027] Combined with the structure of the entire battery module, the heat dissipation installation and fixing structure of the battery cell used for the battery module is described in detail below:

[0028] The battery module includes a bottom support 10 for installing the battery module. The bottom support 10 has an open box-like structure, and the side walls of the bottom support 10 are respectively provided with a module negative terminal 11 and a module positive connection terminal 12. The opening of the bottom bracket 10 is provided with a box cover 20. The battery module includes a plurality of battery packs arranged in parallel. The battery cell 30 located at the outermost side of the battery pack is provided with a supporting frame 40, and a locking screw 41 is arranged between the supporting frames 40 on both sides of the battery pack, and the locking screw 41 is parallel to the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com