Production technique of super-high-speed Dacron and chinlon spinning dual-component crossing composite fiber

A composite fiber and production process technology, which is applied in the production process field of ultra-high-speed spinning polyester-nylon bicomponent interwoven composite fiber, can solve the problems of long process flow, inability to meet quality and quality, complex processing process, etc., and achieve short process flow. , Good moisture absorption and air permeability, and the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

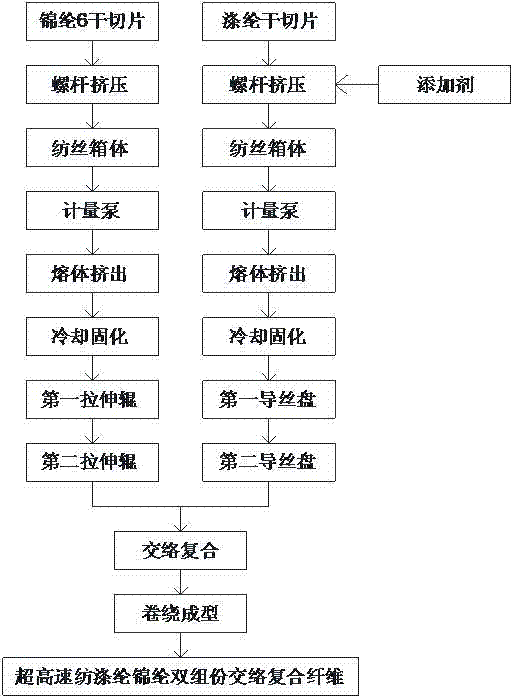

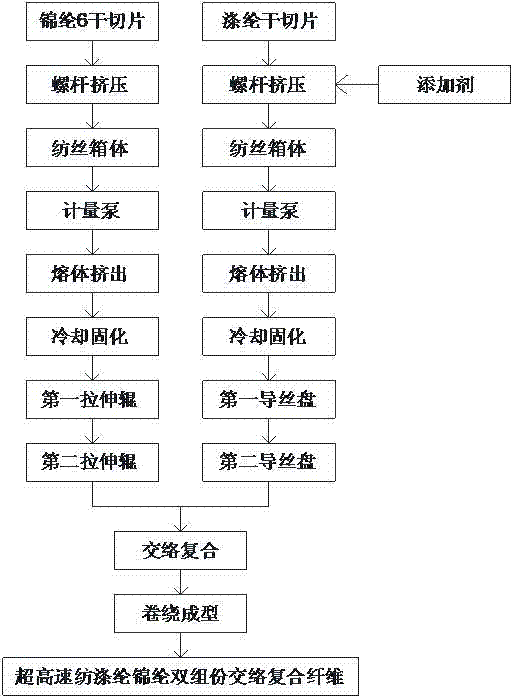

Image

Examples

Embodiment 1

[0019] This example provides a one-step production process of nylon 6 dry chips and polyester dry chips with a content ratio of 4:6, respectively, for melt spinning, special cooling forming, intertwining and compounding, and ultra-high-speed winding forming. The method for preparing ultra-high-speed spinning polyester nylon two-component intertwined composite fiber, its production process and conditions are as follows:

[0020] Add additives and nylon 6 dry chips to polyester dry chips and divide them into two different spinning screw extruders for heating, melting, mixing, metering, and filtration, and then enter into two different spinning boxes, two metering pumps, two Each spinning assembly forms a melt, which is then extruded from the micropores of the two spinnerets, cooled and solidified by the blower cooling device separately set up to form two bundles of filaments, oiled through the nozzle, pre-networked, stretched and heat-set Nylon 6 tows and polyester tows are made...

Embodiment 2

[0022] This example provides a one-step production process using elastic components and non-elastic component raw materials with a content ratio of 5:5, respectively performing melt spinning, special cooling forming, intertwining and compounding, and ultra-high-speed winding forming. The method for preparing ultra-high-speed spinning polyester nylon two-component intertwined composite fiber, its production process and conditions are as follows:

[0023] Add additives and nylon 6 dry chips to polyester dry chips and divide them into two different spinning screw extruders for heating, melting, mixing, metering, and filtration, and then enter into two different spinning boxes, two metering pumps, two Each spinning assembly forms a melt, which is then extruded from the micropores of the two spinnerets, cooled and solidified by the blower cooling device separately set up to form two bundles of filaments, oiled through the nozzle, pre-networked, stretched and heat-set Nylon 6 tows a...

Embodiment 3

[0025] This example provides a one-step production technology using elastic component and non-elastic component raw materials with a content ratio of 6:4, respectively performing melt spinning, special cooling forming, intertwining and compounding, and ultra-high-speed winding forming. The method for preparing ultra-high-speed spinning polyester nylon two-component intertwined composite fiber, its production process and conditions are as follows:

[0026] Add additives and nylon 6 dry chips to polyester dry chips and divide them into two different spinning screw extruders for heating, melting, mixing, metering, and filtration, and then enter into two different spinning boxes, two metering pumps, two Each spinning assembly forms a melt, which is then extruded from the micropores of the two spinnerets, cooled and solidified by the blower cooling device separately set up to form two bundles of filaments, oiled through the nozzle, pre-networked, stretched and heat-set Nylon 6 tows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com