Highly-integrated mechanically-opened type bottle opening valve

A highly integrated, open-type technology, applied in the direction of mechanical equipment, multi-way valves, safety valves, etc., can solve the problems of occupying a large space, inconvenient operation, large structural size, etc., to ensure the safety of system pressure and temperature, and compact structure , highly integrated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

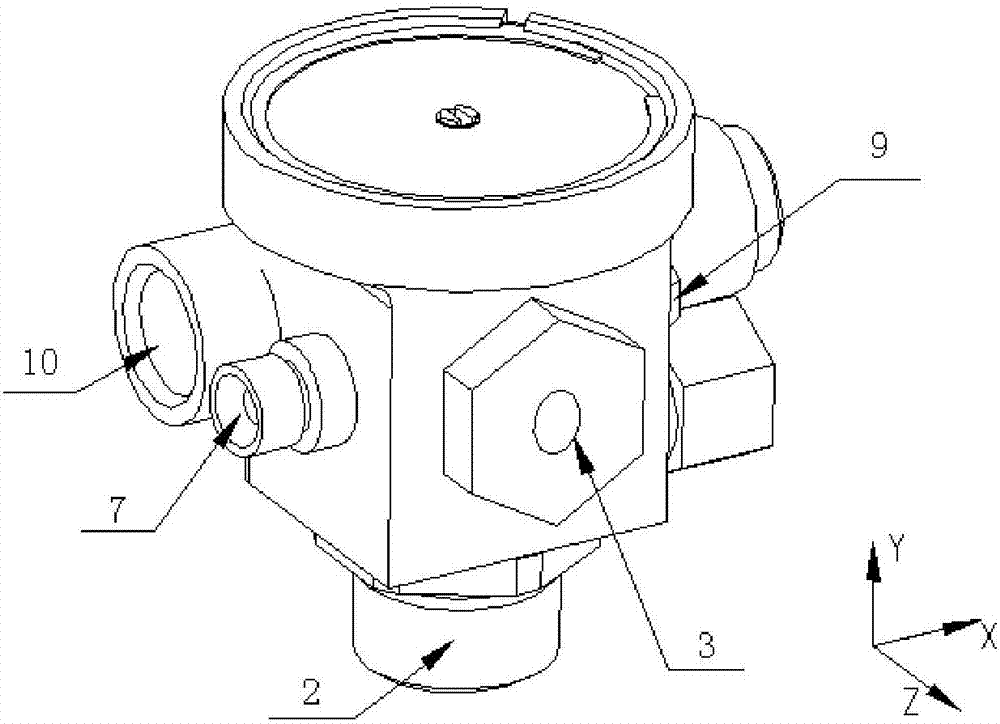

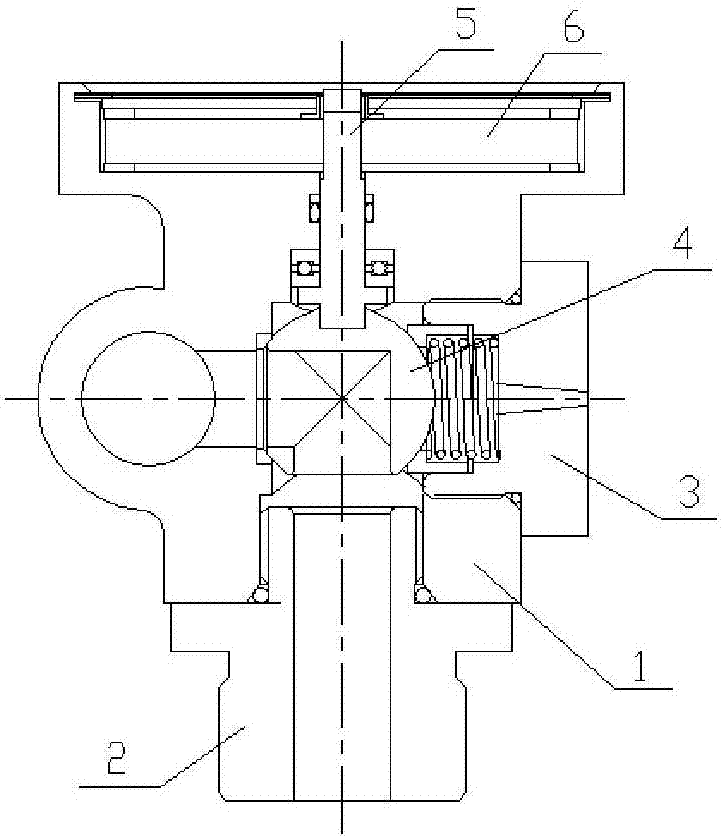

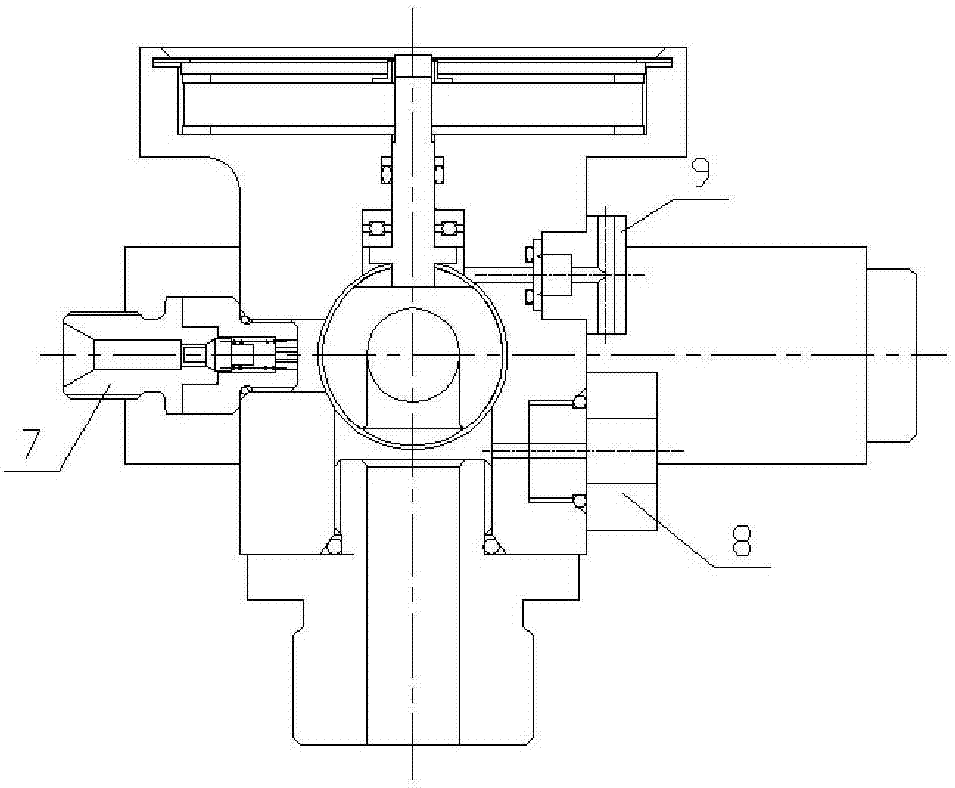

[0021] A highly integrated, mechanically open bottle mouth valve, such as figure 1 As shown, it includes a gas cylinder interface 2, a temperature safety valve 3, a ball valve 4, an inflation valve 7, a pressure safety valve 9 and a pressure reducing valve 10, the gas cylinder interface 2 communicates with the gas cylinder, the inflation valve 7, the pressure reducing valve 10 and the gas cylinder The bottle interface 2 forms a three-way structure, and the ball valve 4 is located in the common gas channel of the three-way structure. A spring is arranged between the gas cylinder interface 2 and the ball valve 4. There is a vent hole leading to the outer wall of the sphere. In the inflated state, adjust the direction of the ball valve 4 so that the inflation valve 7 communicates with the through hole, and then communicates with the gas cylinder through the vent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com