SZ optical cable stranding and cabling machine

A cabling machine and optical cable technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of increasing the additional loss of optical fiber, large walking resistance of the bundle tube, easy stretching and deformation of the bundle tube, etc., to reduce the resistance and structure. Simple, low additional loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

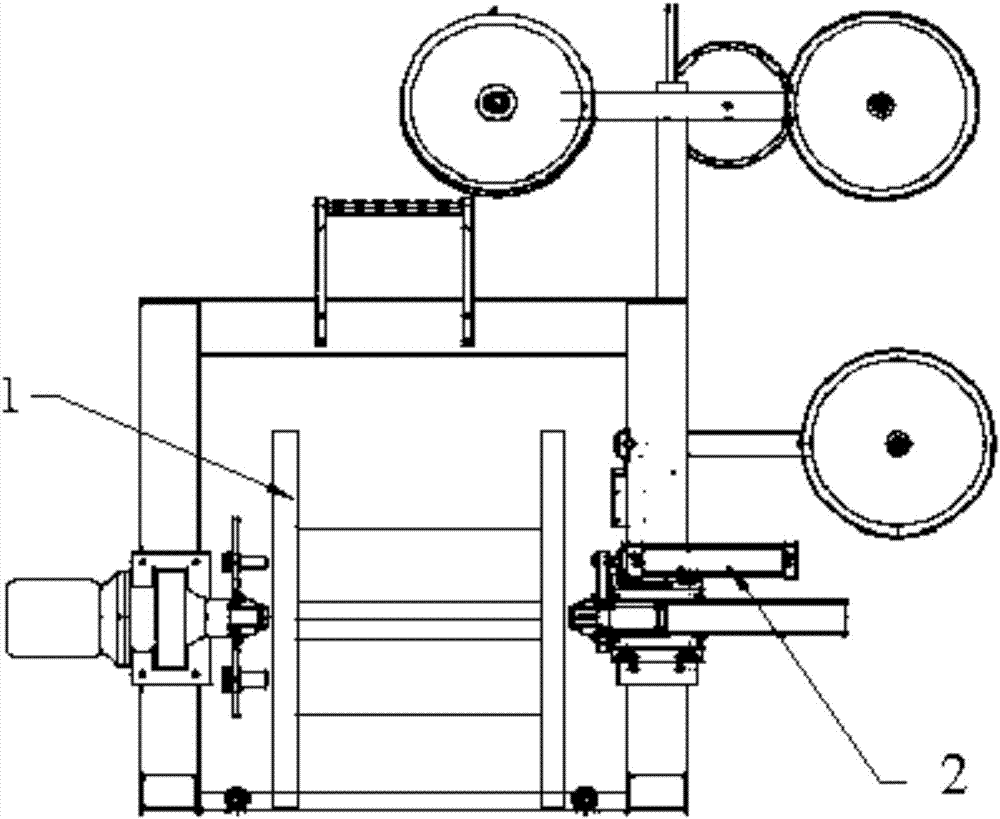

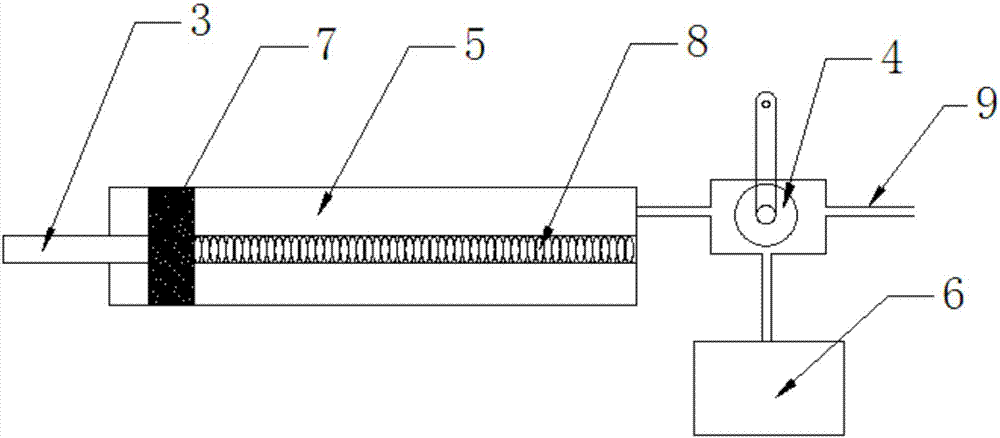

[0015] Such as Figure 1 to Figure 2 As shown, an SZ optical cable stranding machine includes an SZ optical cable stranding machine body 1, such as the QY-JHG-12 / 800 SZ optical cable stranding machine. The SZ optical cable stranding machine body 1 is connected with four motors 2, and the motors 2 are arranged on the SZ optical cable stranding body 1 in sections to form a segmented differential stranding drive. The motors 2 are respectively connected with controllers, through which the differential transmission of the four motors 2 is controlled. The motors are installed in a special bracket, and the special bracket is connected to the bottom of the SZ optical cable stranding machine body. The special bracket includes four connecting rods 3 and a base plate 4, each of the four corners of the base plate 4 is fixed with a connecting rod 3, the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap