Reverse-axis tension active control system for sectional warping machine

An active control system and the technology of the section warping machine, which is applied in the field of textile machinery, can solve the problems of incomplete conversion and large extra energy consumption, and achieve the effect of stable control and small extra loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

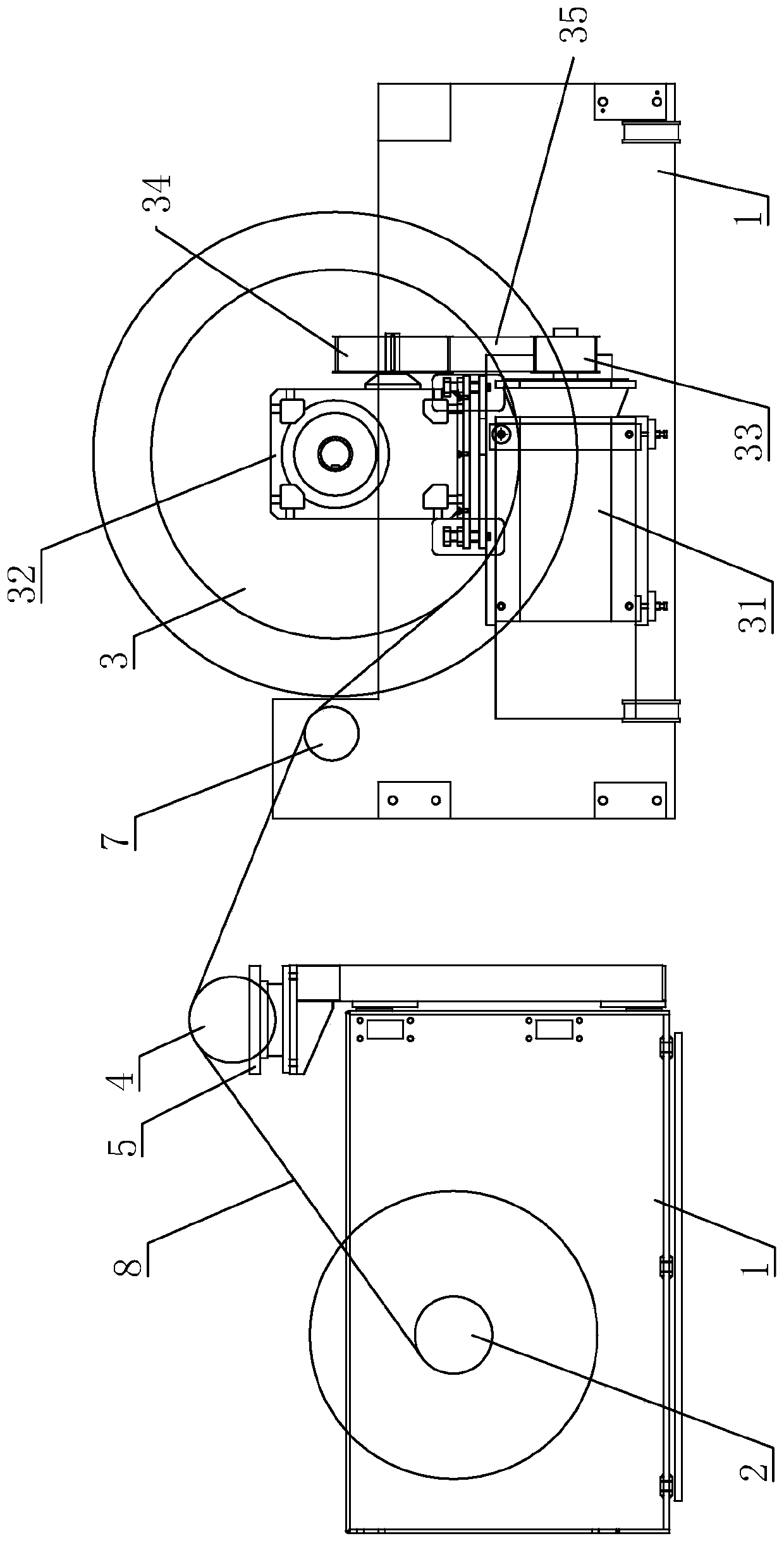

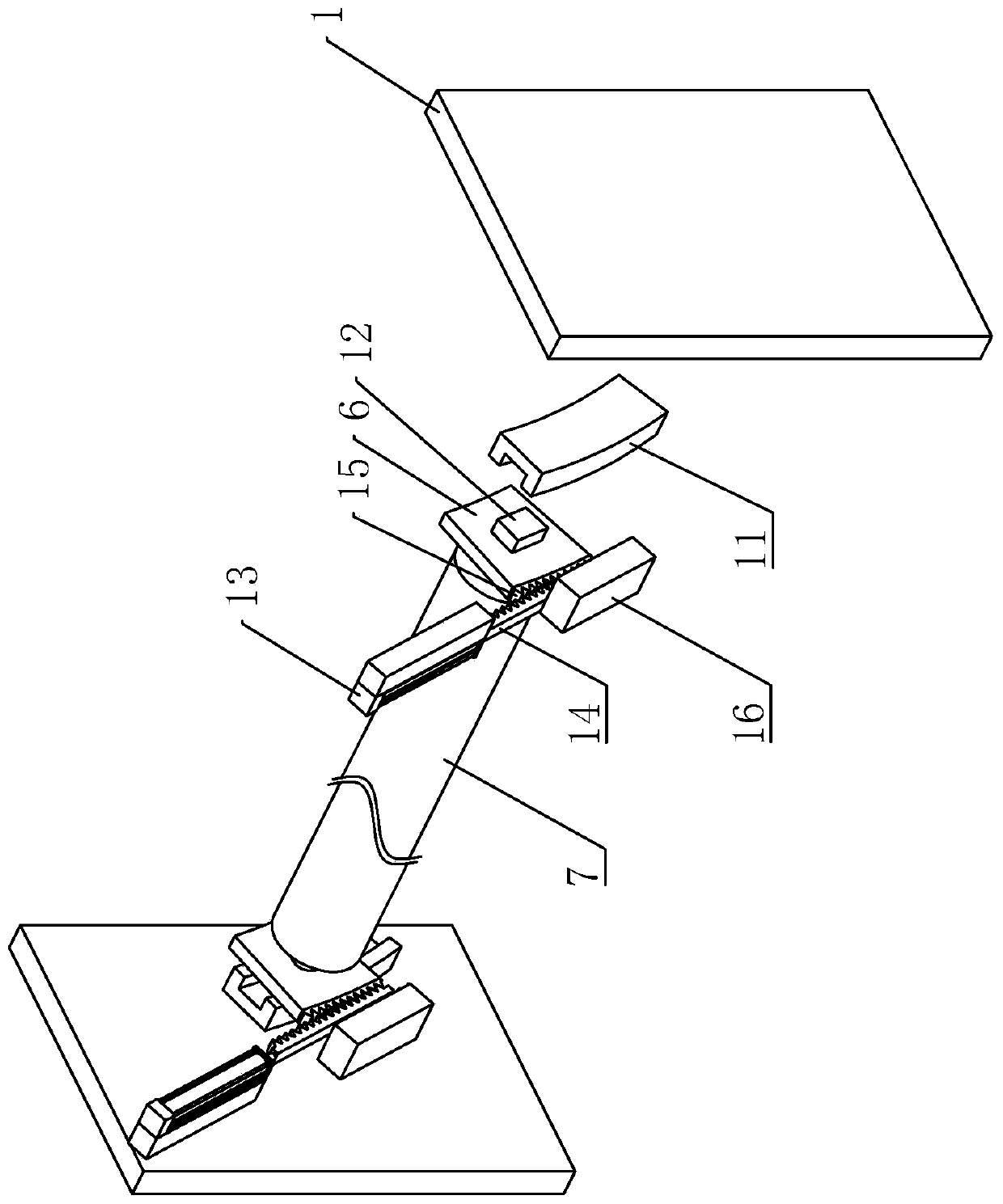

[0035] An active control system of inverted axis tension for section warping machines, such as figure 1 As shown, it includes a frame 1, on which a guide roller 3, a guide roller 7, a tension roller 4 and a warp beam 2 are erected successively on the frame 1, and the above-mentioned structures are all connected with the frame 1 in rotation, along the direction of travel of the yarn 8 aligned and parallel to each other.

[0036] Such asfigure 1 As shown, a motor assembly is erected on the frame 1 , including a first motor 31 and a reducer 32 . Wherein, the output shaft of the first motor 31 is provided with a driving pulley 33, the input shaft of the reducer 32 is provided with a driven pulley 34, and the driving pulley 33 and the driven pulley 34 are wound with a transmission belt. 35, the output shaft of speed reducer 32 then links to each other with guide roller 3. The motor assembly drives the yarn guide roller 3 to rotate, and controls the speed at which the yarn guide r...

Embodiment 2

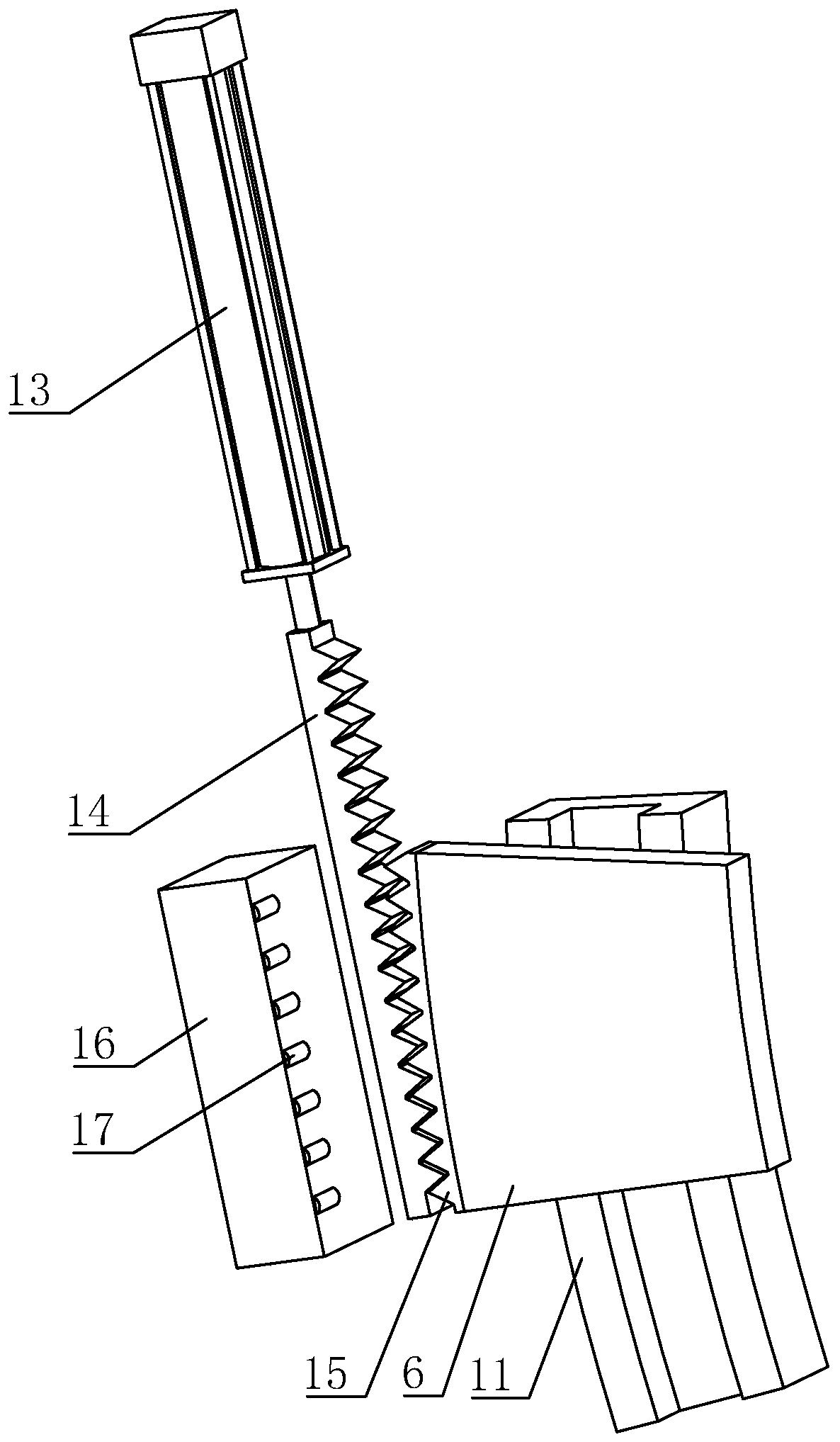

[0049] The difference from Embodiment 1 is that the driving assembly that drives the adjustment seat 6 to slide is different, such as Figure 4 As shown, the frame 1 is mounted with a screw 19 and a second motor 111 . The screw rod 19 is arranged along the tangential direction of the slide rail 11 , is connected in rotation with the frame 1 , is connected with the output shaft of the second motor 111 , and rotates under the drive of the second motor 111 . In addition, the screw rod 19 is sleeved with a shifting block 18, and the two are screwed together. One end of the shifting block 18 facing the center of the slide rail 11 is provided with a draw slot 110 , and the draw slot 110 is arranged along the normal direction of the slide rail 11 . Correspondingly, a shift lever 61 is welded on the adjustment seat 6 . The driving rod 61 is parallel to the guide roller 7 and is installed in the slot 110 , and its diameter is equal to the width of the slot 110 .

[0050] Such as F...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap