Solid wood ecological plate flatness control method

A control method and flatness technology, which is applied in the jointing of wooden veneers, manufacturing tools, wood processing appliances, etc., can solve the problems of easy deformation, moisture content change, cracking, etc., to prevent the change of board material and reduce moisture content The effect of rate change and flatness change is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

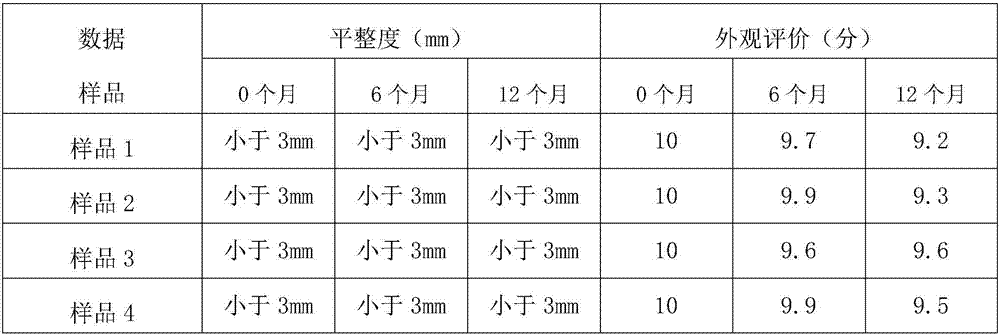

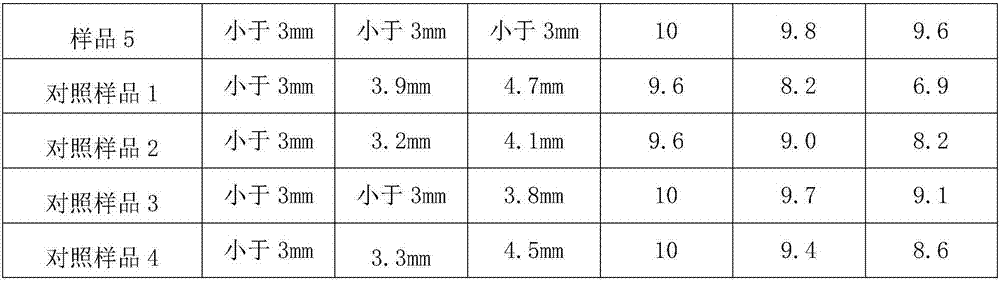

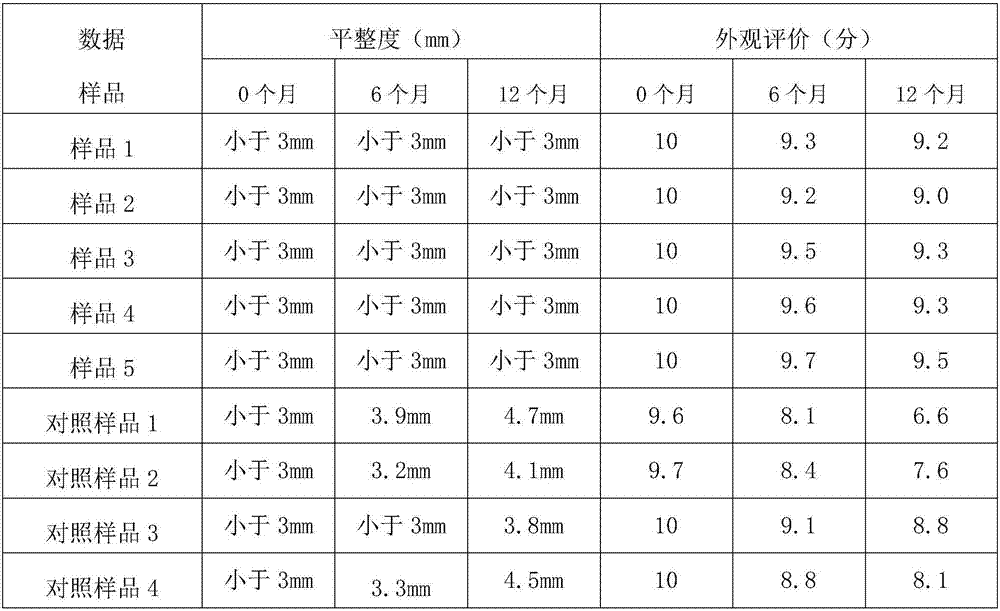

Examples

Embodiment 1

[0035] A method for controlling the flatness of a solid wood ecological board, comprising the following steps:

[0036] a. Scraping the solid wood core: First use wood chips to fill up the recesses of the solid wood core with a diameter > 15mm, and then use ash scraping material A to scrape the solid wood core; wherein, the solid wood core is 3cm in width, 45cm in length, It is formed by splicing 12mm thick slats, and the slat raw materials are selected from common Chinese fir;

[0037] Wherein, the ash-scraping material A comprises the following raw materials by weight: 20 parts of wood bran, 200 parts of glue, and 7 parts of flour.

[0038] b. Solid wood board core sanding: the solid wood board core is evenly sanded on both sides, and the flatness of the same board after sanding is within -2 ~ 2mm;

[0039] c. The solid wood core and the eucalyptus chips are laminated and pressed to form a rough board: the solid wood core is coated with glue on both sides, and after air-dry...

Embodiment 2

[0046] A method for controlling the flatness of a solid wood ecological board, comprising the following steps:

[0047] a. Scraping the solid wood core: First use wood chips to fill up the recesses of the solid wood core with a diameter > 18mm, and then use ash scraping material A to scrape the solid wood core; wherein, the solid wood core is 7cm in width, 55cm in length, It is formed by splicing 18mm thick slats, and the raw material of the slats is selected from Chinese fir;

[0048] Among them, the scraping material A includes the following raw materials in parts by weight: 40 parts of wood bran, 230 parts of glue, and 25 parts of flour.

[0049] b. Solid wood board core sanding: The solid wood board core is sanded evenly on both sides, and the flatness of the same board after sanding is within -1.5 ~ 1.5mm;

[0050] c. The solid wood core and eucalyptus chips are laminated and pressed to form a rough board: the solid wood core is coated with glue on both sides, and after ...

Embodiment 3

[0057] A method for controlling the flatness of a solid wood ecological board, comprising the following steps:

[0058] a. Solid wood core scraping: First use wood chips to fill up the recesses of the solid wood core with a diameter > 16mm, and then use ash scraping material A to scrape the solid wood core; wherein, the solid wood core is 4cm in width, 48cm in length, It is formed by splicing 14mm thick slats, and the slat raw materials are selected from Chinese fir;

[0059] Wherein, the dust-scraping material A includes the following raw materials in parts by weight: 25 parts of wood bran, 210 parts of glue, and 11 parts of flour.

[0060] b. Solid wood board core sanding: The solid wood board core is sanded evenly on both sides, and the flatness of the same board after sanding is within -1.0 ~ 1.0mm;

[0061] c. The solid wood core and eucalyptus chips are laminated and pressed to form a rough board: the solid wood core is coated with glue on both sides, and after air-dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com