Flying and climbing robot for bridge crack detection

A technology of robots and bridges, which is applied in the field of flying and climbing robots, can solve the problems of large hovering error of aircraft, limited endurance, and limitation of the working space of the bridge inspection vehicle's outrigger, so as to realize the perception of attitude, solve the problem of poor endurance, and realize The effect of stable flight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments, so as to make the purpose, technical solutions and advantages of the present invention more clear. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

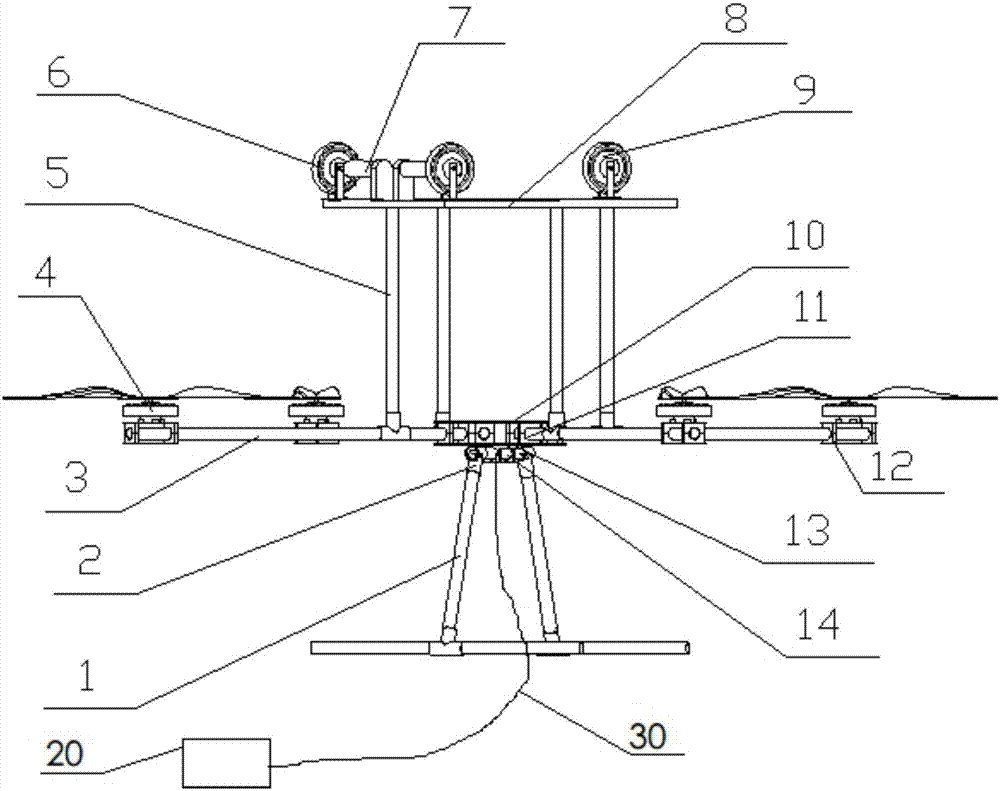

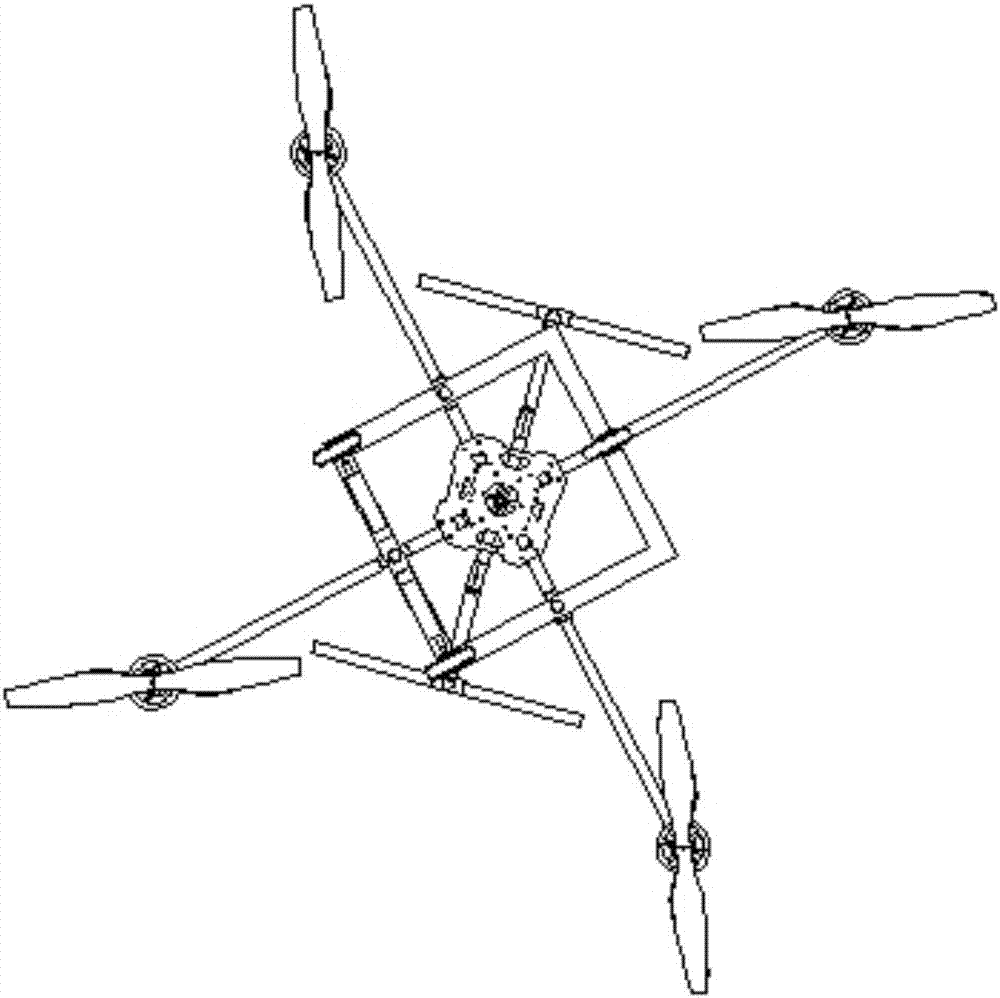

[0027] figure 1 with figure 2 A front view and a top view of the flying-climbing robot according to an embodiment of the present invention are respectively shown. The flying-climbing robot of this embodiment integrates four-axis aircraft, tethered balanced take-off, tethered cable power supply, and wall-mounted precise motion control. It can cling to the bottom of the bridge deck after hovering, and realize high Accuracy detection and power supply through the tethered rope to achieve continuous high-efficiency work.

[0028] Such as figure 1 As mentioned, one end of at least two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com