Automatic discharging device of storage trays on security check line

A storage tray and automatic technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of reduced site utilization, high labor costs, and low work efficiency, and achieve a simple structure, low production cost, and easy manufacturing and processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

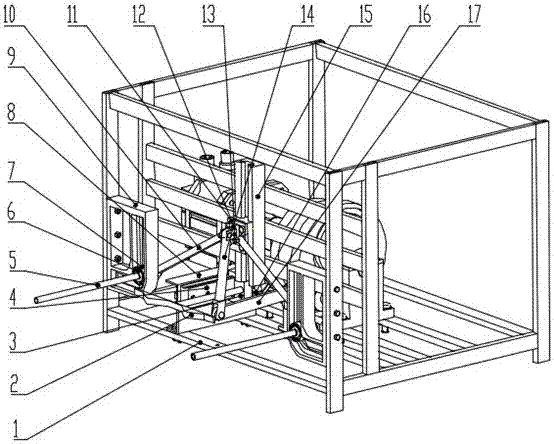

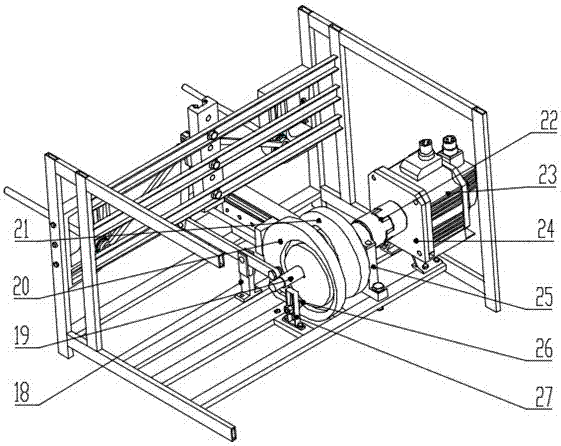

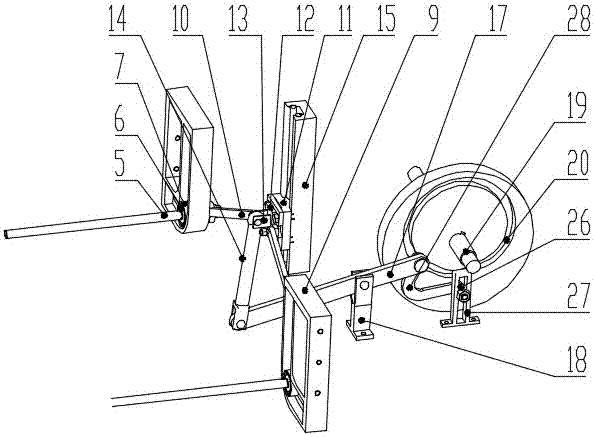

[0016] Such as Figure 1-7 As shown, the present invention includes a frame 1, a driving device, a disk-taking mechanism and a mechanism for pushing the disk; the frame 1 adopts a pipe section weldment; the driving device includes a motor seat 24, two bearing blocks 25 , motor 23, input shaft 19 and shaft coupling 22; described motor seat 24 and two bearing seats 25 are fixed on the frame 1 with bolts respectively, and motor 23 is fixed on the motor seat 24 by screws, and input shaft 19 passes through The bearings are installed in two bearing housings 25, and the shaft of the motor 23 is connected with the input shaft 19 through a coupling 22.

[0017] The disc fetching and sending mechanism includes a support seat 18, a guide seat 27, an L-shaped guide seat 9, a double-axis linear slide rail 15, a disc sending cam 20, a swing rod 17, a V-shaped connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com