A quasi-differential temperature heat treatment method for large-size rolls

A technology of warm heat treatment and large size, which is applied in the field of heat treatment, can solve the problems of limited size of the inner cavity of the furnace, unable to meet the design requirements, unable to realize the heat treatment of large size rolls, etc., and achieve the effect of ensuring the temperature heat treatment with tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0032] The invention discloses a quasi-differential temperature heat treatment method for large-size rolls, which is used for heat treatment of large-size rolls. The following are specific examples.

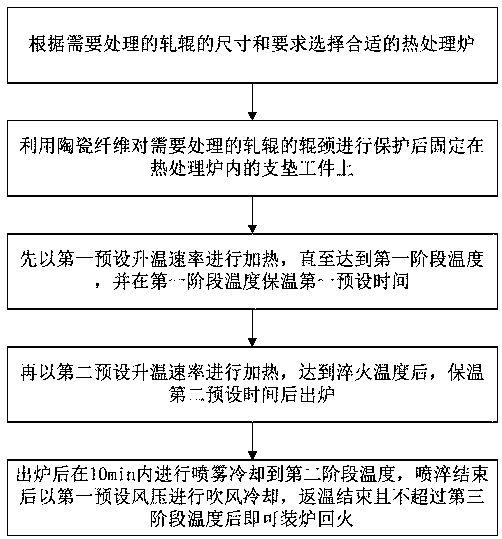

[0033] The invention discloses a quasi-differential temperature heat treatment method for a large-size roll. The method can realize the treatment effect that the roll neck and the core still have a certain toughness while the surface of the roll body is quenched to a certain thickness. figure 1 It is a flowchart of the method, and the method includes the following steps:

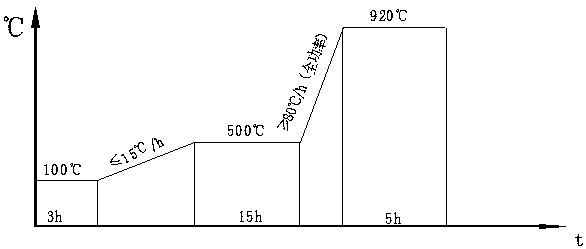

[0034] 1) According to the diameter of the roll body to be processed is 800mm-1800mm, the quenching thickness required for the working layer is 50mm, the selected box-type resistance furnace is 12000mm long, 3000mm wide, and 2200mm high, and the heating power is not less than 5K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com