Air-assisted manual gear shifting mechanism

A shift mechanism and power-assisted technology, applied in the field of the shift mechanism of a manual transmission of a truck, can solve the problems affecting the normal driving of the vehicle, difficult shifting operations, and difficulty in shifting, so as to avoid accidental shifting and improve shifting efficiency. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

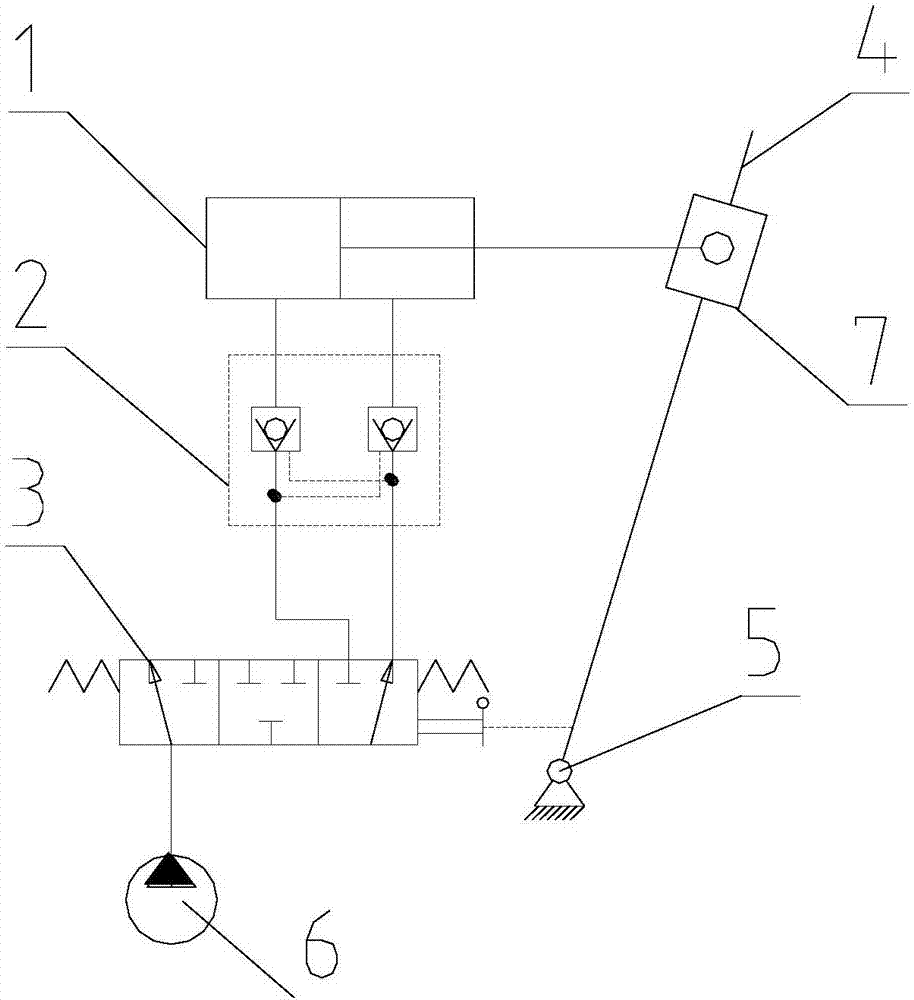

[0024] refer to figure 1 Embodiments of the present invention will be described.

[0025] Pneumatic-assisted manual shift mechanism, including booster cylinder 1, hydraulic lock 2, reversing valve 3, slider 7, shift arm 4 and casing 5, wherein booster cylinder 1 is connected with hydraulic lock 2, and hydraulic lock 2 is connected with Reversing valve 3 is connected.

[0026] One end of the shift swing arm 4 is connected to the shell 5 through a hinge, on which a slider 7 is installed, and the slider 7 can also move up and down along the shift swing arm 4, and the slider 7 is connected to the piston rod of the booster cylinder 1 through a hinge, .

[0027] The reversing valve 3 is connected with the shifting arm 4, and when the shifting handle 4 swings, it can drive the reversing valve 6 to change the flow direction of the compressed air.

[0028] The reversing valve 6 is a three-position three-way valve of the middle seal type.

[0029] When working, the driver's shifting...

Embodiment 2

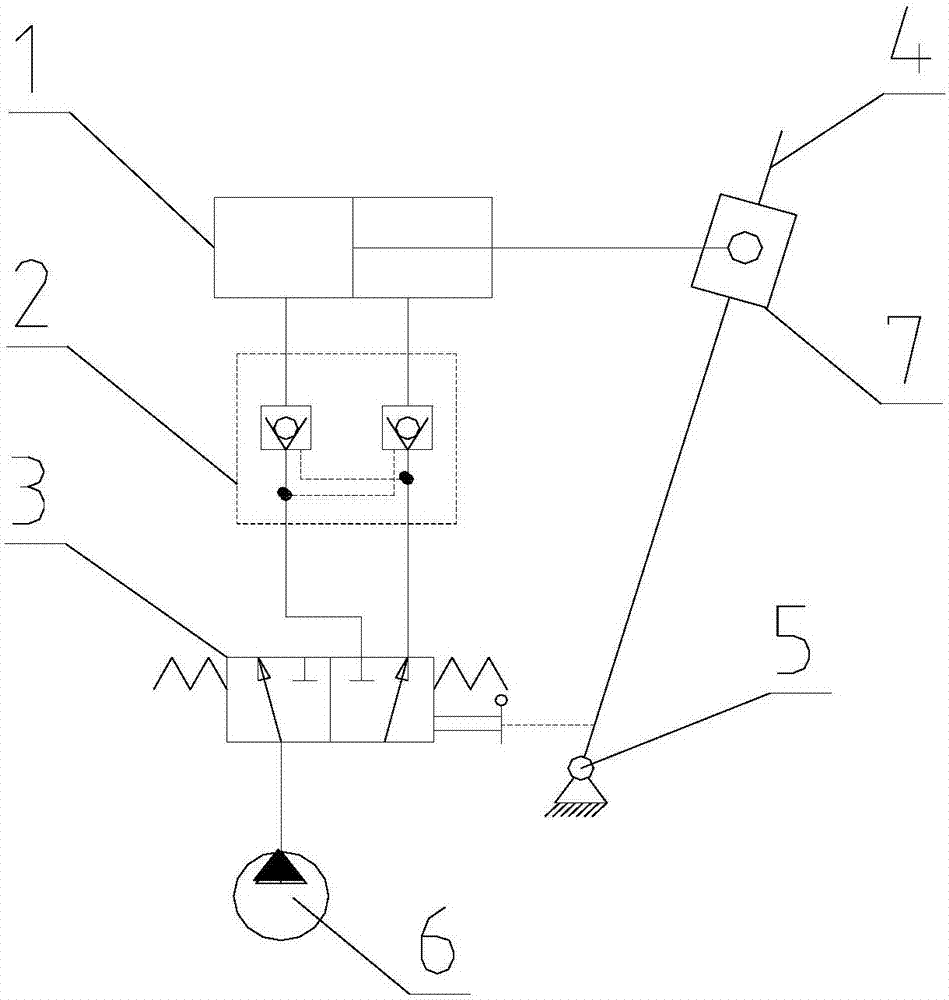

[0031] refer to figure 2 Embodiments of the present invention will be described.

[0032] The reversing valve 6 is a two-position three-way valve, and the remaining parts are the same as in the first embodiment.

Embodiment 3

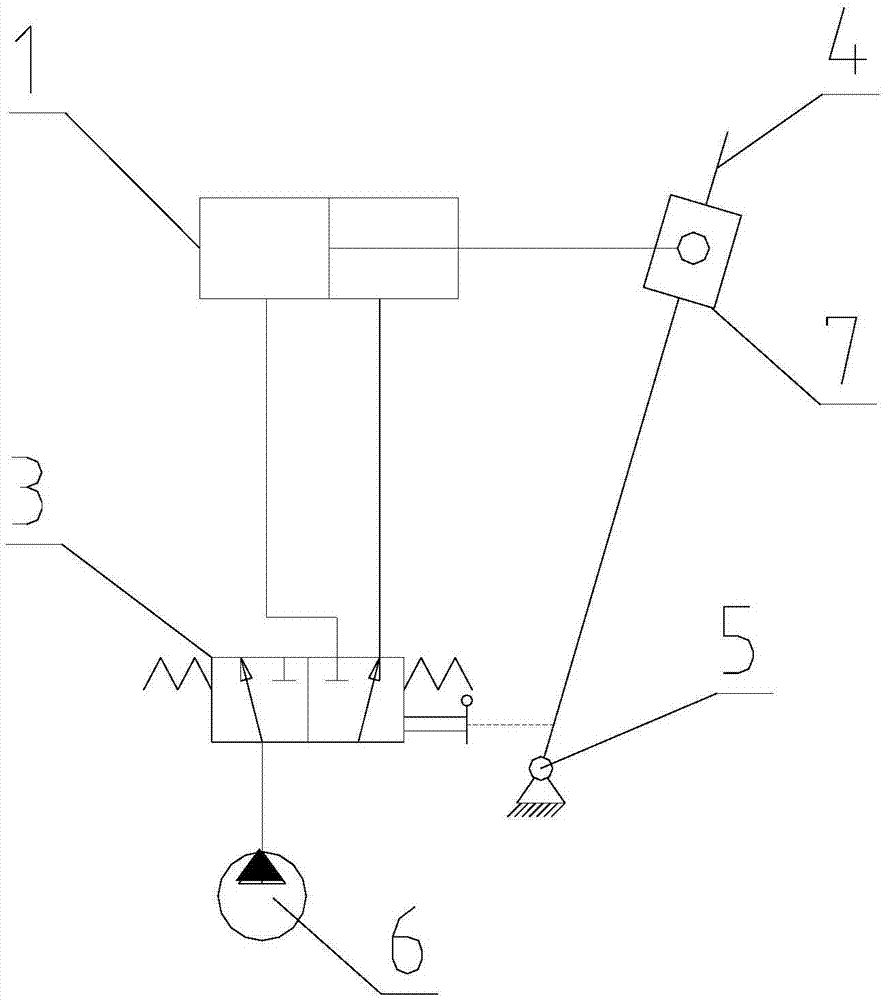

[0034] refer to image 3 Embodiments of the present invention will be described.

[0035] This embodiment is suitable for occasions where the reliability of gear shifting is not high, and the hydraulic lock 2 is eliminated in the air circuit, and the rest is the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com