A simulation device for fluid fracture seepage under high temperature stress

A seepage simulation, high temperature technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem that the holder is difficult to guarantee, and achieve accurate temperature measurement results, accurate results, and test results precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

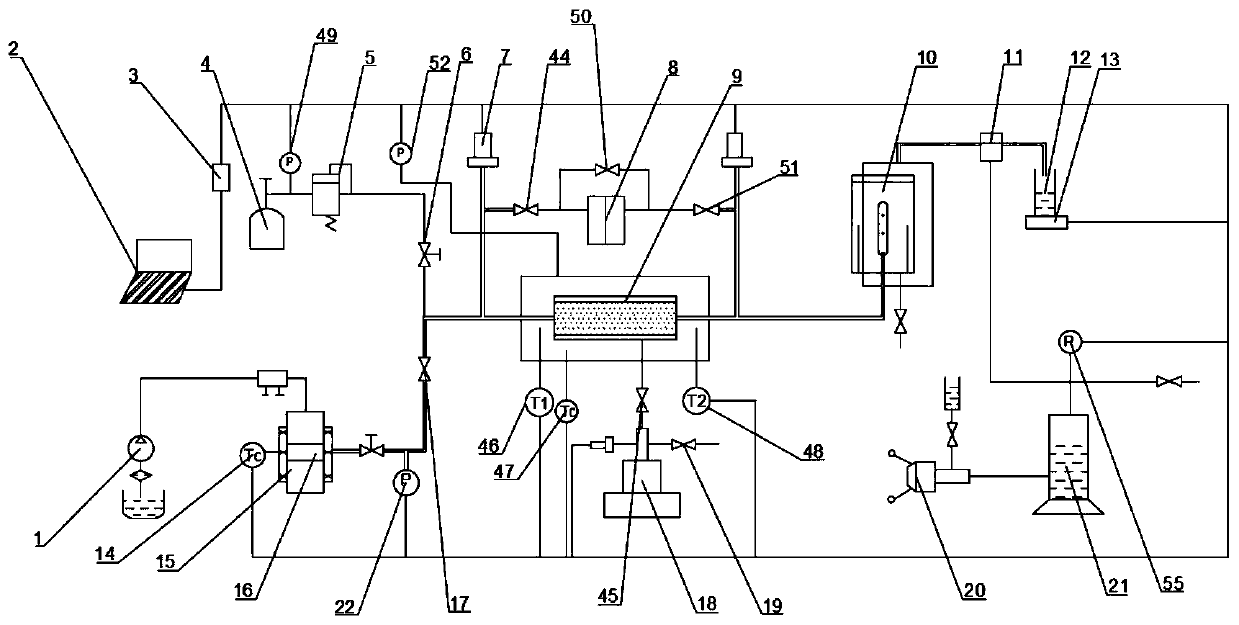

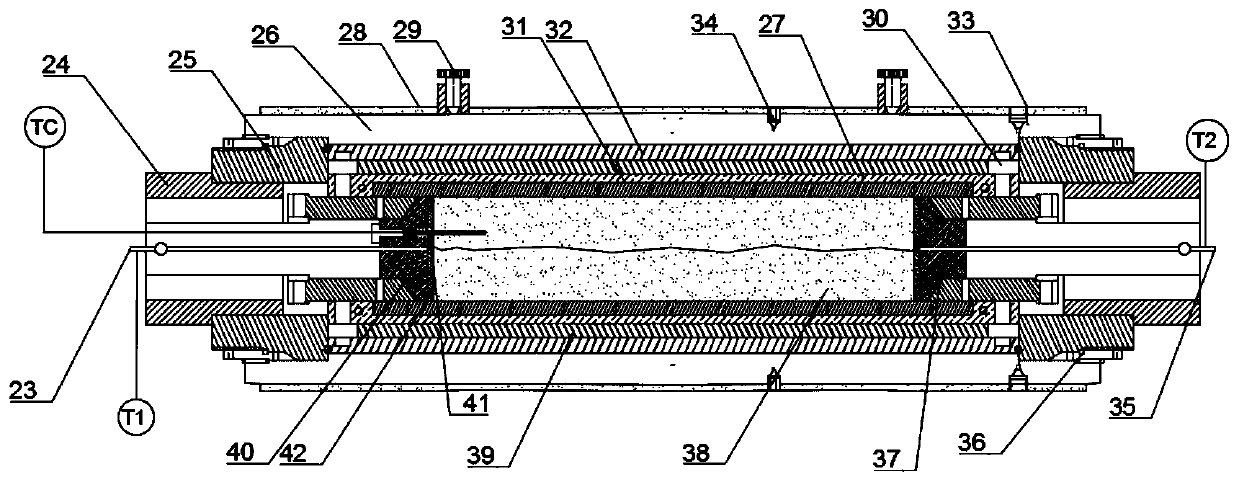

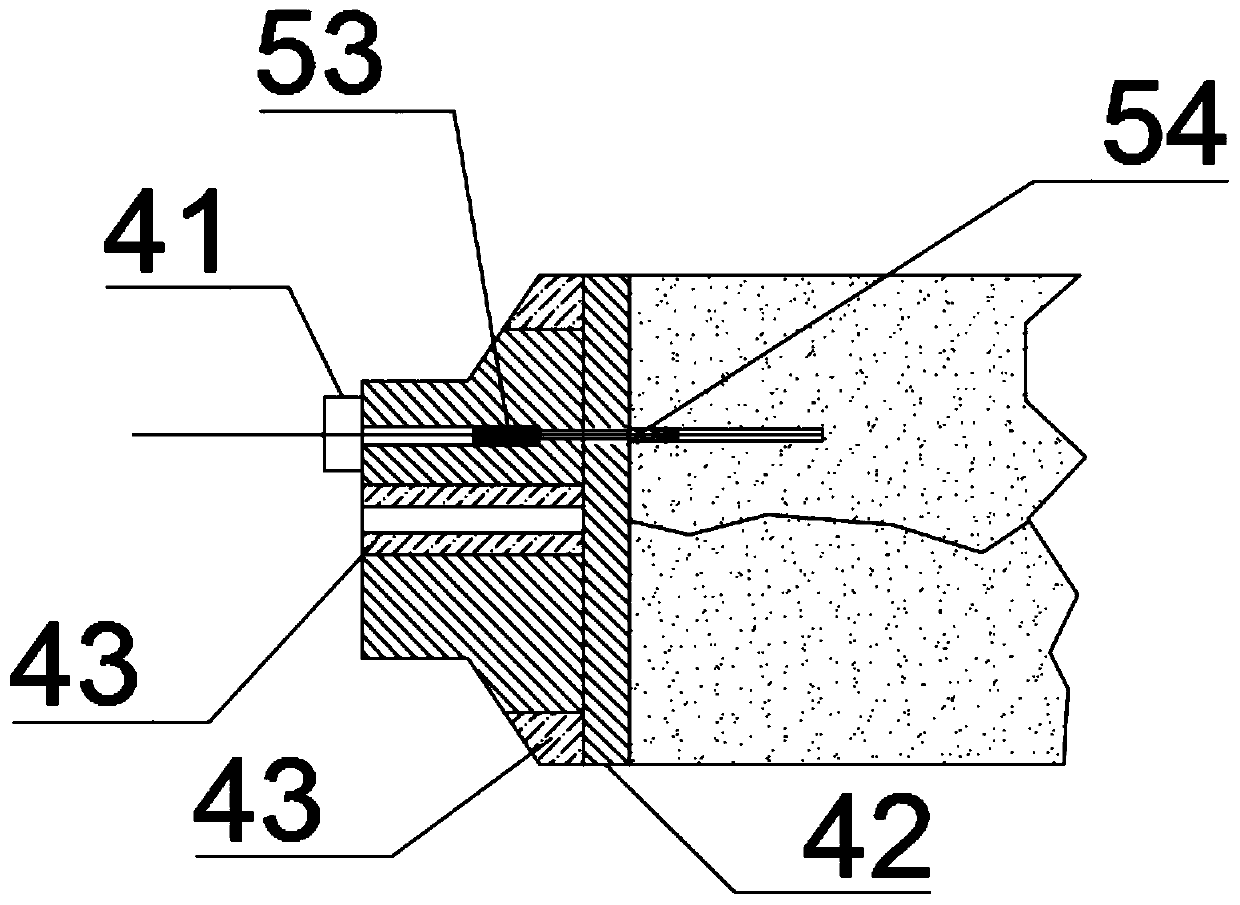

[0029] Such as figure 1 and figure 2 and image 3 As shown, the present invention includes an injection system, a pressure control system, a high-temperature core holder and a temperature control system, and the high-temperature core holder 9 includes a core chamber 38, a thermal layer 27, a copper sleeve 31, a thermal insulation Interlayer 39, rubber sleeve 32, shell 28, injection plug 40, output plug 37, anti-seepage partition 42, adjustment plug 25 and fixed plug 24, rock core chamber 38 two ends have anti-seepage partition 42, The left side of the anti-seepage partition 42 at the injection end is equipped with an injection plug 40, and the anti-seepage partition 42 and the injection plug 40 at the injection end all have a small hole for the probe of the temperature meter 3 47 to enter the inside of the rock mass. There is a sealing bolt 41 at the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com