Processing method of uncentered clamping

A processing method and clamping technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problems such as difficulty in guaranteeing the processing quality of parts, achieve the effect of improving utilization rate, reducing human participation rate, and ensuring no stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

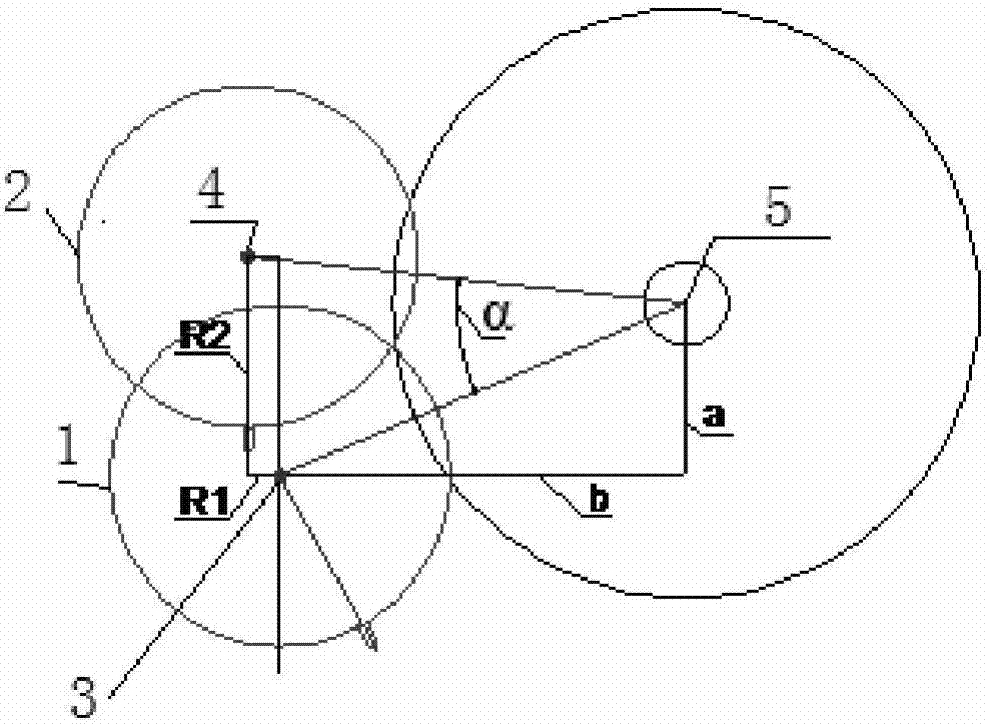

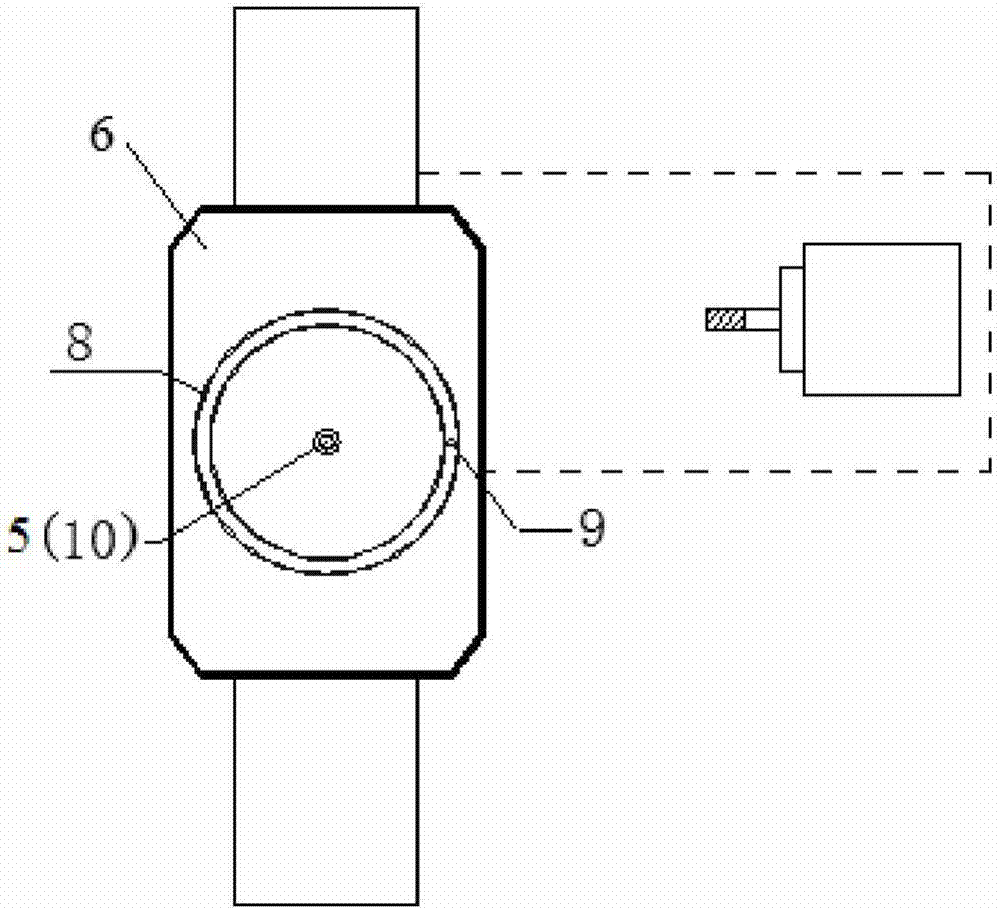

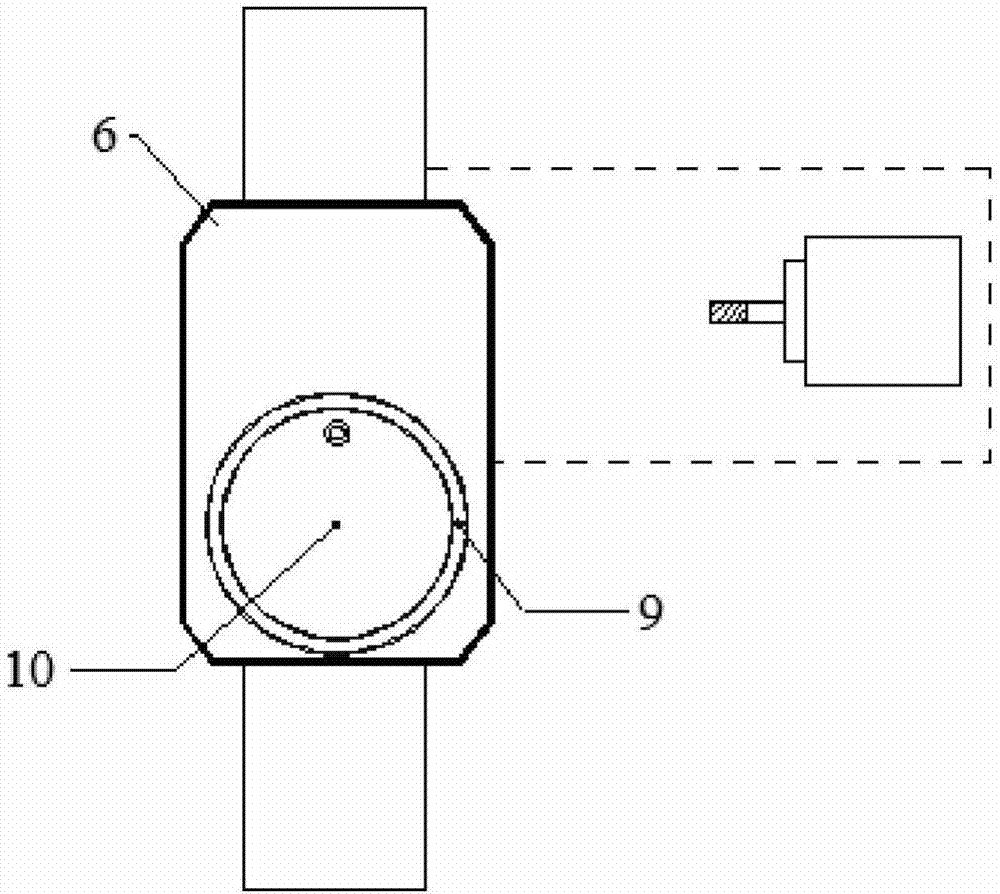

[0039] A processing method of non-centering clamping in the present invention ensures that the spatial position between the program origin and the part body is correct during the change process through compensation for the displacement of the program origin, and the steps are as follows:

[0040] Use online measurement technology to determine the center of parts at any position;

[0041] Realize program origin tracking according to the center of the part, and calculate the corresponding offset when the part angle changes;

[0042] Compensate the origin of the program according to the offset;

[0043] The origin compensation value is automatically compensated into the program to complete subsequent processing.

[0044] In the present invention, the change rule of the angle should satisfy that no matter where the part is placed, its theoretical rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com