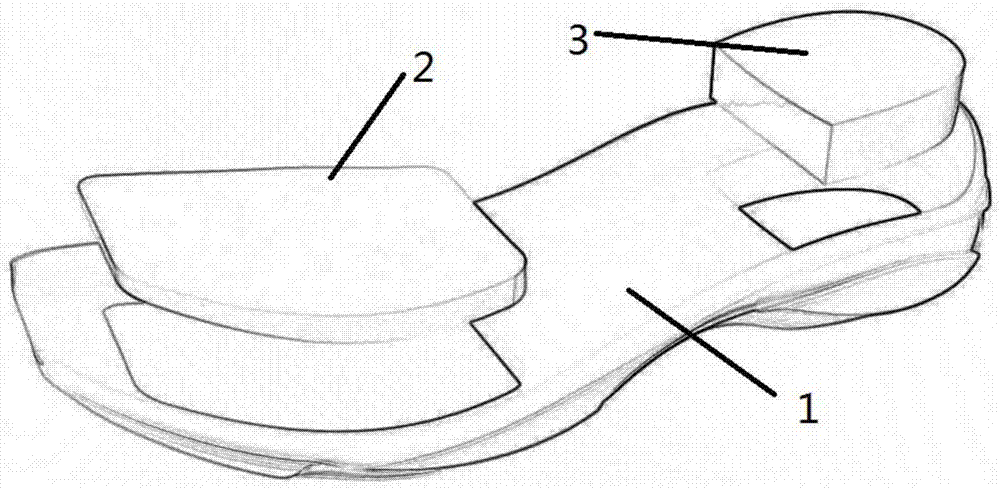

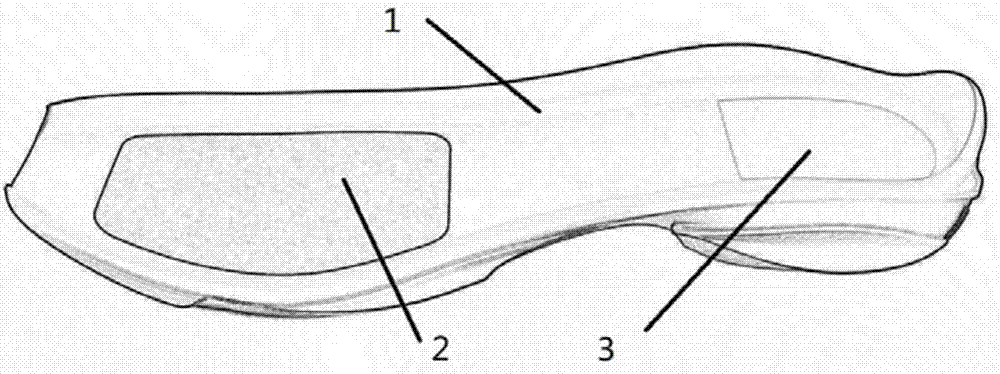

Multi-density durable elastic damping foaming insole and formula

A multi-density and durable technology, applied in the field of foam midsole, can solve the problems of high compression deformation rate, poor tear performance, and unsatisfactory performance, and achieve good compression resistance and bump resistance, good wear resistance, and slow down The effect of fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] The preparation of embodiment, multi-density durable elastic shock-absorbing foam midsole

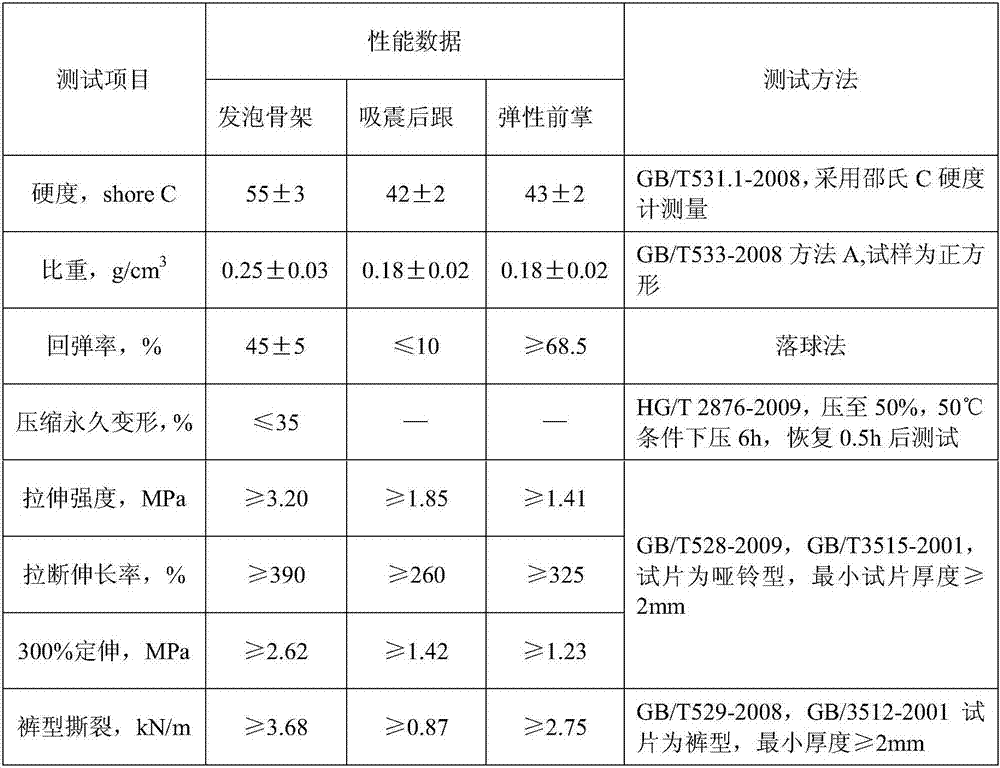

[0054] The rubber-plastic foam skeleton is made of the following components: EVA 7470 25kg; POE 8150 50kg; natural rubber 10kg; talcum powder 10kg; foaming agent AC 3kg; zinc oxide 1.6kg; bridging agent DCP 0.5kg; stearic acid 1.2kg; titanium dioxide 2.0kg; the density of the obtained rubber-plastic foam skeleton is (0.25±0.03)g / cm 3 .

[0055] The high elastic forefoot is made of the following components: EVA 7470 25kg; POE 8060 15kg; POE 7467 20kg; talcum powder 5kg; foaming agent AC 1.9kg; bridging agent DCP 0.25kg; zinc oxide 0.8kg; stearic acid 0.3kg, the density of the obtained high elastic forefoot is (0.18±0.02)g / cm 3 .

[0056] The energy-absorbing and shock-absorbing heel is made of the following components: EVA 609 45kg; talcum powder 5kg; plasticizer DOP 3kg; foaming agent AC 1.5kg; bridging agent DCP 0.25kg; kg, the density of the resulting energy-absorbing shock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com