Multifunctional molecular sieve dehydrating tower

A technology of molecular sieve and dehydration tower, which is applied in the field of multifunctional molecular sieve dehydration tower, can solve the problems of easily damaged internal heating natural gas molecular sieve dehydration device and reduce the service life of internal heating natural gas molecular sieve dehydration device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

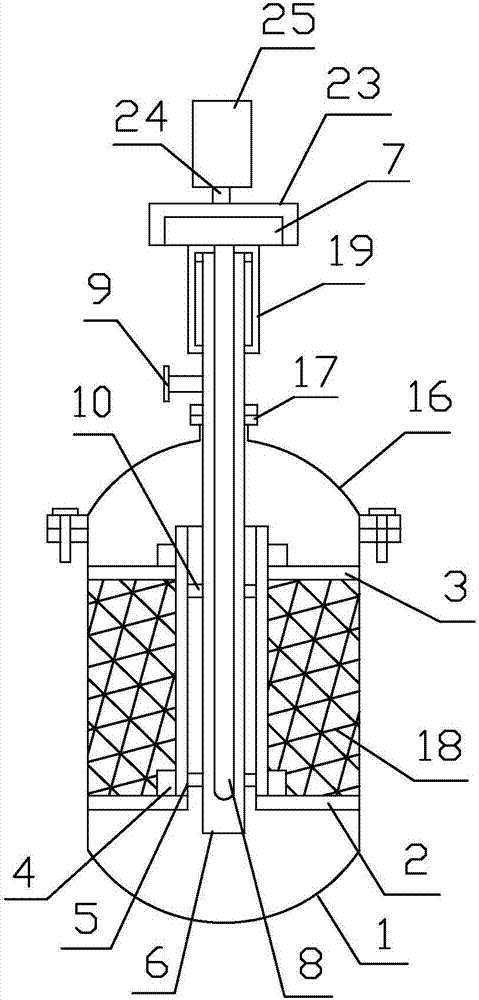

[0032] like Figure 1~3As shown, the multifunctional molecular sieve dehydration tower of the present invention includes a vertical cylindrical shell 1, and a first supporting mesh plate 2 is arranged in the shell 1 near the axial bottom end, and a first support screen 2 is arranged in the shell 1 near the axial top end. A second support net plate 3 is provided, and the center of the first support net plate 2 and the second support net plate 3 are provided with installation through holes, and the upper support net plate 2 and the second support net plate 3 There is a threaded connection sleeve 4 protruding from the center of the circle on the surface of the board; it also includes a mounting sleeve 5 and a central sleeve 6, and the axial top and bottom outer walls of the mounting sleeve 5 are provided with the threaded sleeve 5. The external thread of the connecting sleeve 4 is adapted, and the mounting sleeve 5 is installed on the first support net plate 2 and the second supp...

Embodiment 2

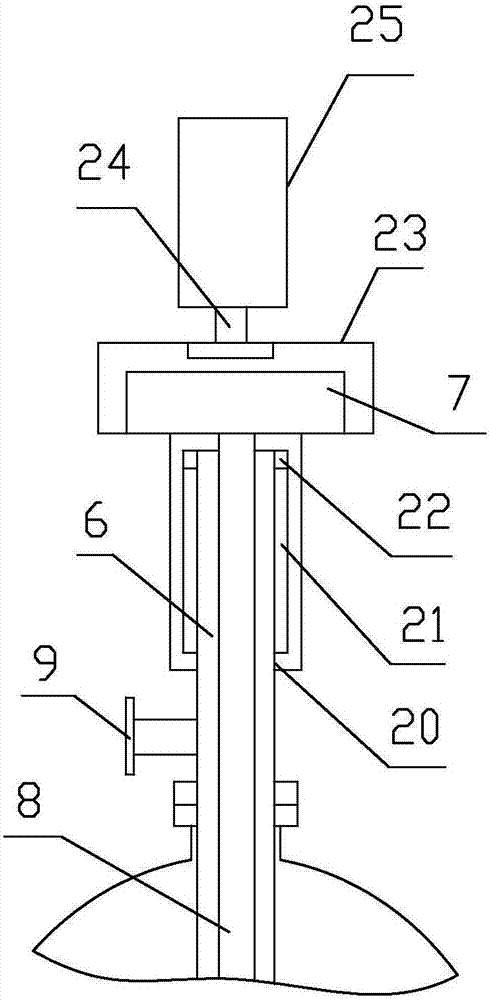

[0034] Further improvement on the basis of Example 1, the adjustment sleeve 19 is provided with a threaded through hole 20 and an adjustment hole 21 in sequence from the outside to the inside, the axis line of the adjustment sleeve 19 and the axis center of the threaded through hole 20 line and the axis line of the adjustment hole 21 all coincide; the inner diameter of the adjustment hole 21 is greater than the inner diameter of the threaded through hole 21, the threaded through hole 20 is adapted to the external thread of the central sleeve 6, and the axial top end of the central sleeve 6 A limiting plate 22 is arranged around the side wall along the axial direction, and the outer diameter of the limiting plate 22 is smaller than the inner diameter of the adjustment hole 21 and larger than the inner diameter of the threaded through hole 20 . The axial top end of the adjustment sleeve 19 is welded with an installation housing 23, which is used to install the electric heater 7 i...

Embodiment 3

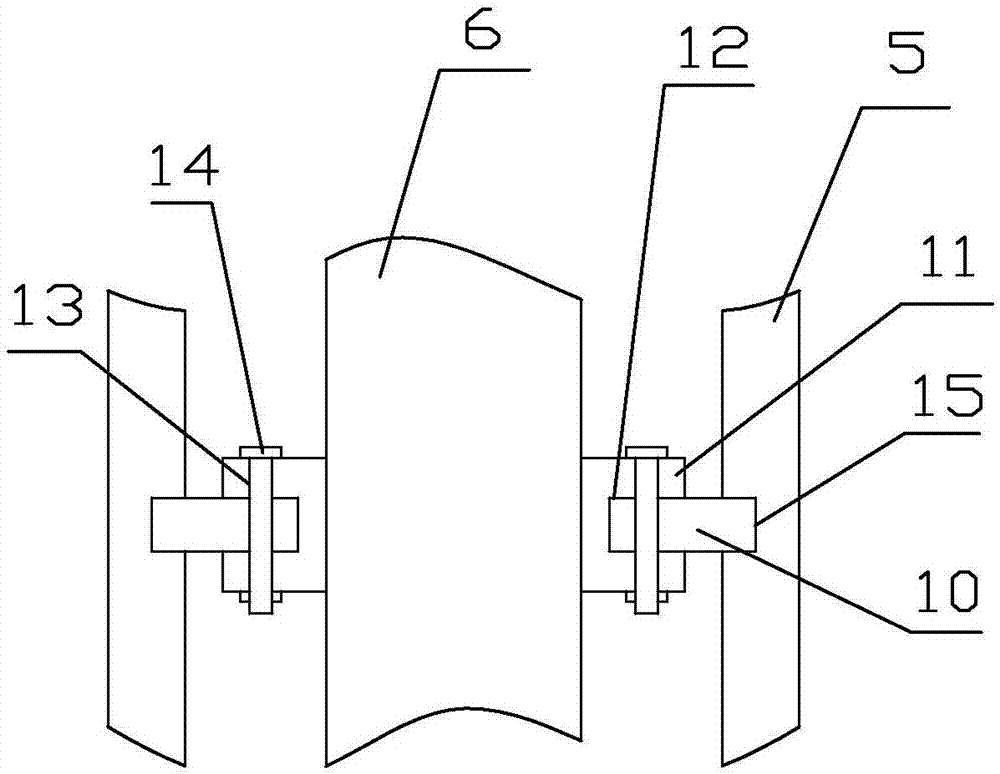

[0036] Further improvement on the basis of Embodiment 2, the side wall of the central sleeve 6 is provided with a mounting block 11 along the circumferential ring, the side wall of the mounting block 11 is provided with a limiting groove 12 along the circumferential ring, and the mounting block 9 is also provided with There is a threaded hole 13, the axial direction of the threaded hole 13 is perpendicular to the extension direction of the limiting groove 12, and the threaded hole 13 runs through the limiting groove 12; the rubber sealing ring 10 is sleeved on the mounting hole 11, and The radial end is embedded in the limiting groove 12 for sealing rubber ring installation, and the rubber sealing ring 10 is fixed on the mounting block 11 through the threaded hole 13 on the mounting block 11 and the rubber sealing ring 10 embedded in the limiting groove 12 through the bolt 14; The part of the rubber sealing ring 10 located outside the limiting groove 12 is pressed and fixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com