Treatment technology for residual aluminum in aluminum profile extrusion die

An extrusion die and processing technology, applied in the field of residual aluminum processing technology, can solve problems such as low practicability, damage to the surface of the die, and failure to distinguish impact aluminum alloy or steel welds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

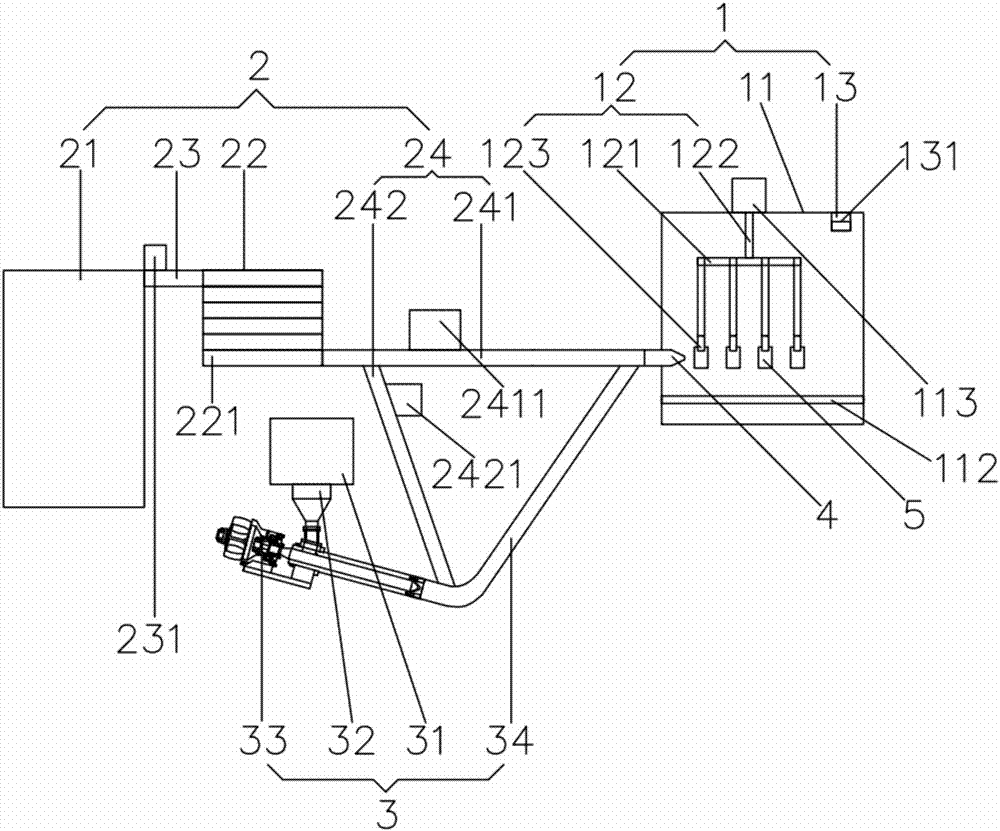

[0049] A process for treating residual aluminum in an aluminum profile extrusion die of the present invention, such as figure 1 As shown, a residual aluminum treatment process in an aluminum profile extrusion die comprises the following steps:

[0050] (1) After the extrusion of the aluminum profile is completed, the mold 5 is removed and cooled, and then the upper mold and the lower mold are separated;

[0051] (2) Put the upper mold and the lower mold into a sodium hydroxide solution with a weight concentration of 26-28% for alkali washing to remove oil;

[0052] (3) The upper mold and the lower mold after alkali washing are firstly washed with recycled waste water, and then washed with clean water for the second time;

[0053] (4) Dry the upper and lower molds;

[0054] (5) Put the upper mold and the lower mold into the vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com