Primary machining method for baseline of bearing frame casting piece of oblique support plate

A technology of oblique support and preliminary processing, which is applied in the direction of metal processing equipment, manufacturing tools, turning equipment, etc., can solve problems affecting the production efficiency of processing units, waste of equipment and personnel, and scrapping of castings, so as to improve processing capacity and improve processing The effect of improving efficiency and improving the dimensional accuracy of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0045] A benchmark preliminary processing method for a load-bearing frame casting of a slanted support plate, the preliminary processing method is as follows:

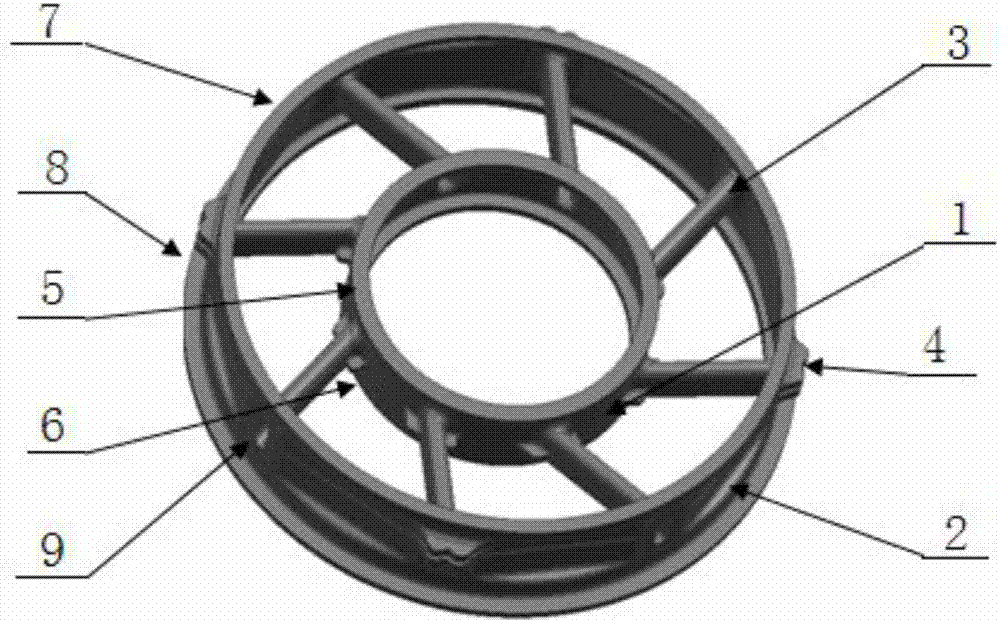

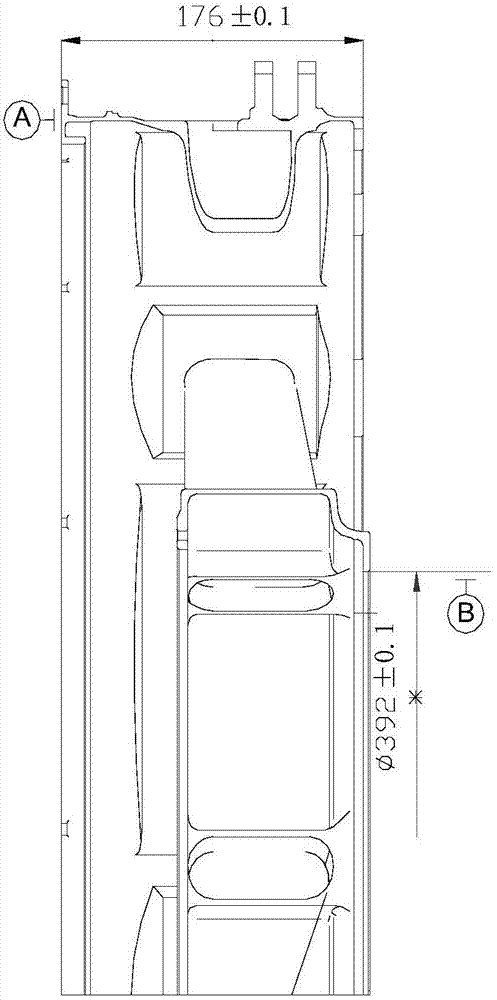

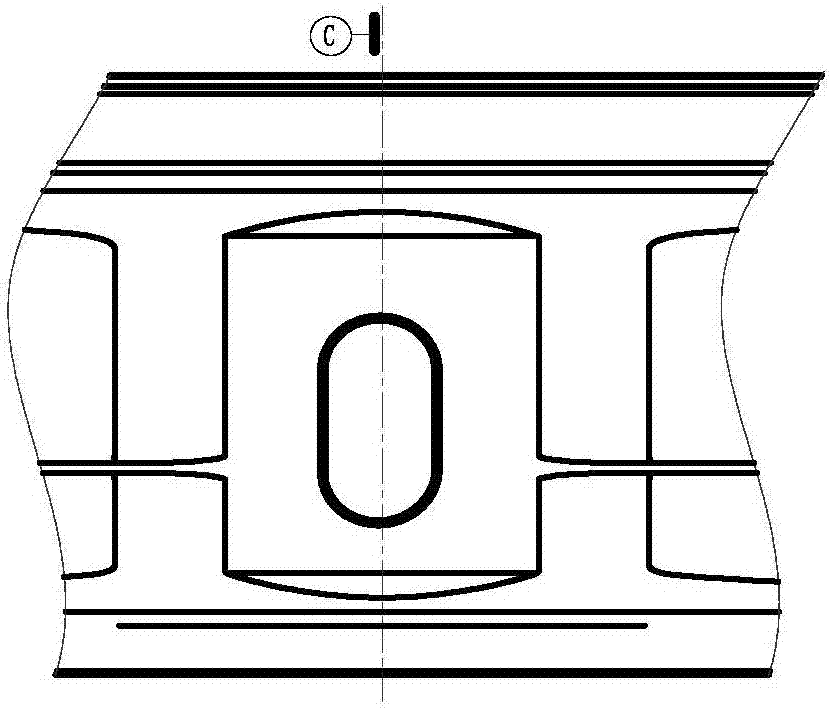

[0046] (1) The end surface A of the rear mounting edge of the outer ring is used as the axial reference, the inner hole B of the front mounting edge of the inner ring is used as the radial reference of the casting, and the center C of the inclined support plate is used as the angular reference;

[0047] (2) There is a margin of 3mm at the A and B benchmarks, and the surface gloss is Ra3.2; the dimensional accuracy of A, B, and C benchmarks is ±0.1mm.

[0048] The specific processing steps of the primary processing method are as follows:

[0049] Step 1: Scribe to check the axial machining allowance

[0050] Put the casting on the marking platform, take into account the relative position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com