Auto-induction air door dust removing system and control method thereof

A technology of automatic induction and dust removal system, used in manufacturing tools, auxiliary devices, plasma welding equipment, etc., can solve the problems of high noise, difficult to guarantee the accuracy of the raceway, and the whole set of devices is scrapped, so as to achieve the effect of easy search.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be described more clearly and completely below in conjunction with the drawings in the embodiments of the present invention.

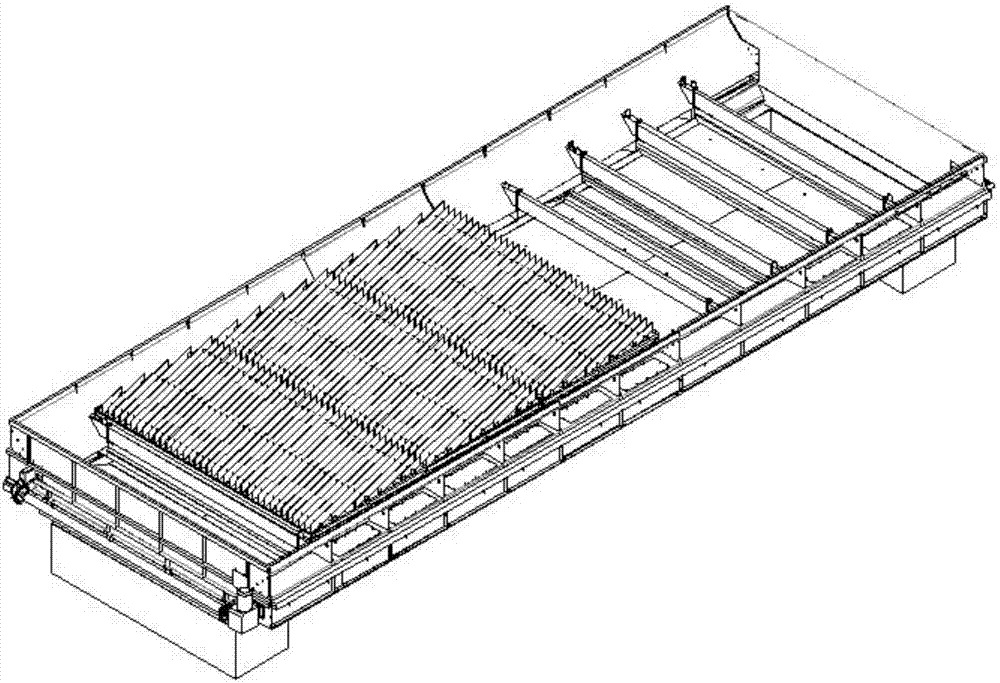

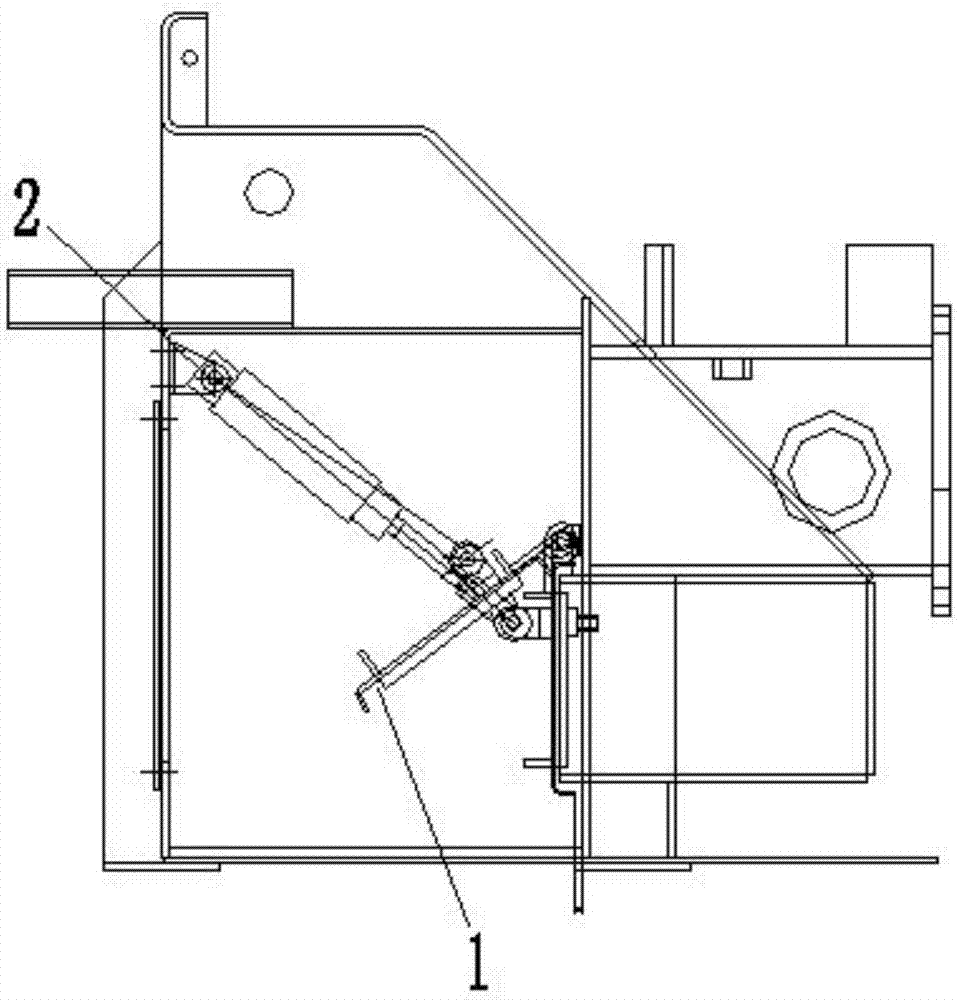

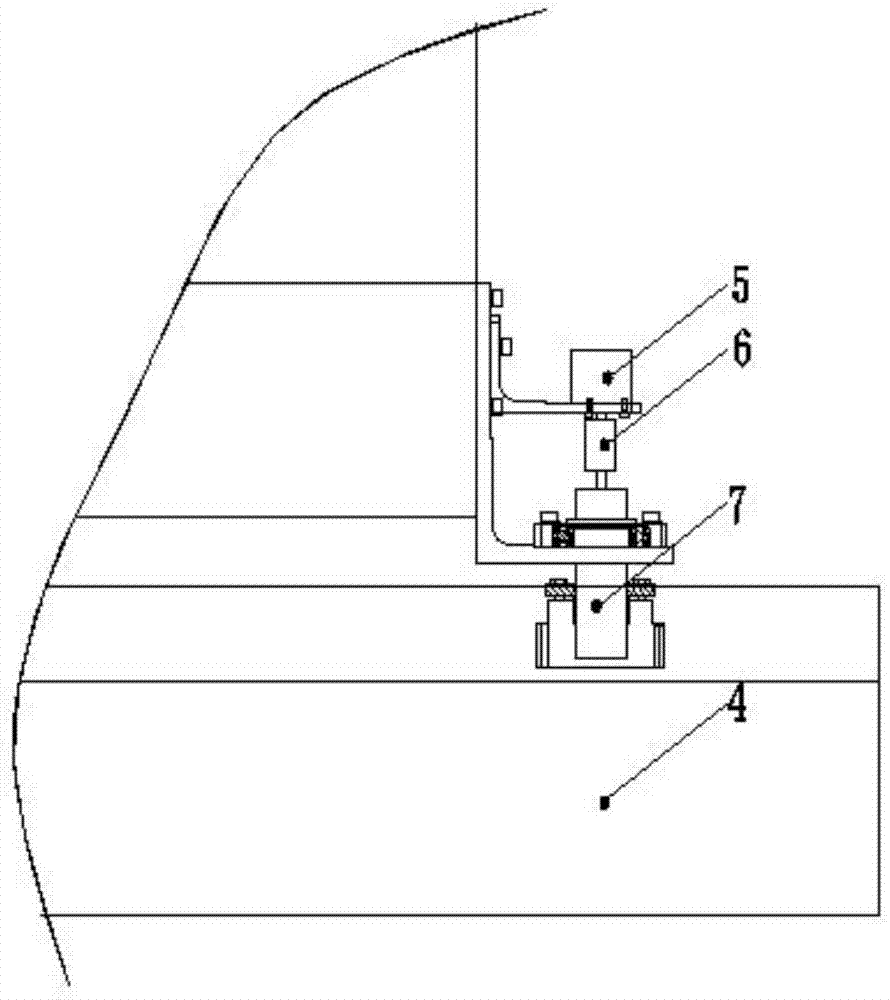

[0034] Figure 1~4 Shown is the structure diagram and installation diagram of the automatic induction damper dust removal system of the present invention, wherein said damper induction dust removal system has several dampers 1, driving equipment 3, displacement detection device 5, driving guide rail 4 and controller 8, and the driving equipment 3 is set On the driving track 4; a displacement detection device 5 and a laser cutting head (marked in the figure) are installed on the driving equipment 3; a switch unit 2 is installed in each of the dampers 1; the controller 8 is connected with the displacement detection The device 5 is electrically connected to the switch unit 2 .

[0035] figure 2 As shown, the displacement detection unit 5 is used to detect the displacement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com