Cracking processing device for crankcase bearing seat

A technology for processing devices and crankcases, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult processing of wedge-shaped tie rods, high equipment manufacturing costs, complicated working processes, etc., so as to avoid pressure rod instability. , Small footprint, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below in conjunction with accompanying drawing:

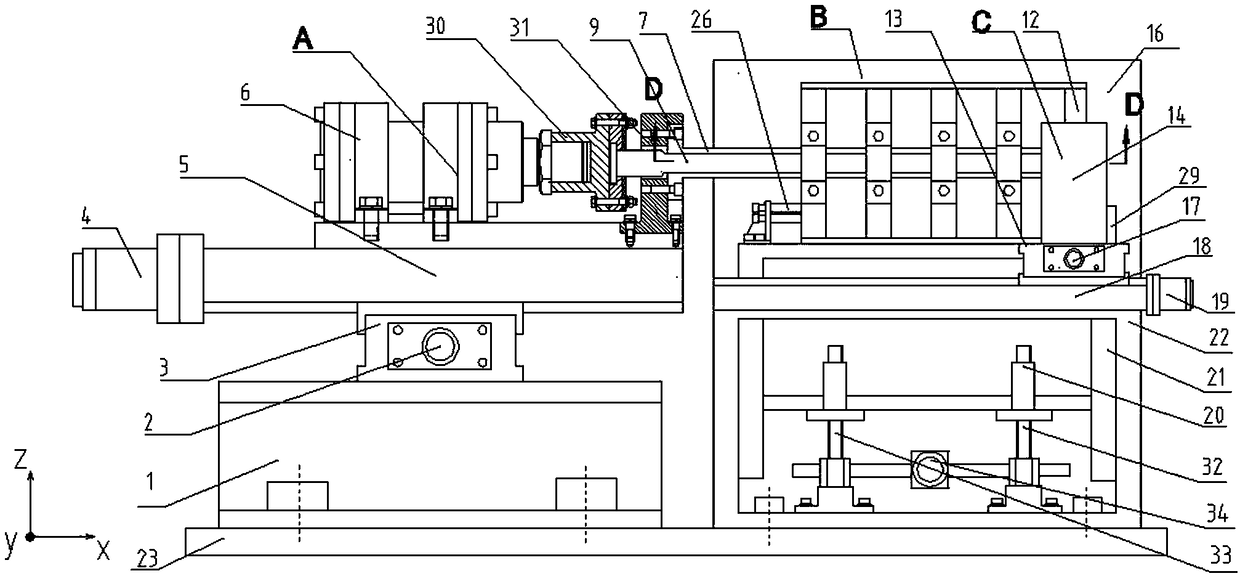

[0041] refer to figure 1 and Figure 5 , A cracking processing device for a crankcase bearing seat according to the present invention includes a machine base 23, a cracking mechanism A, a box positioning mechanism B and a slider mechanism C.

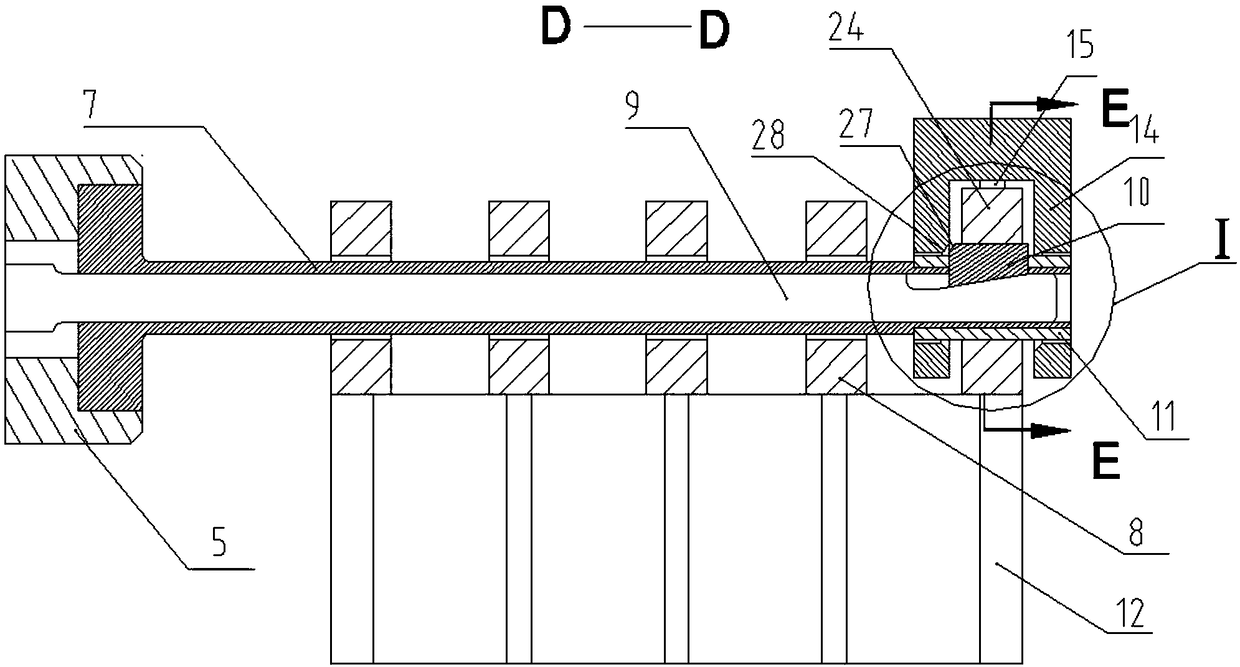

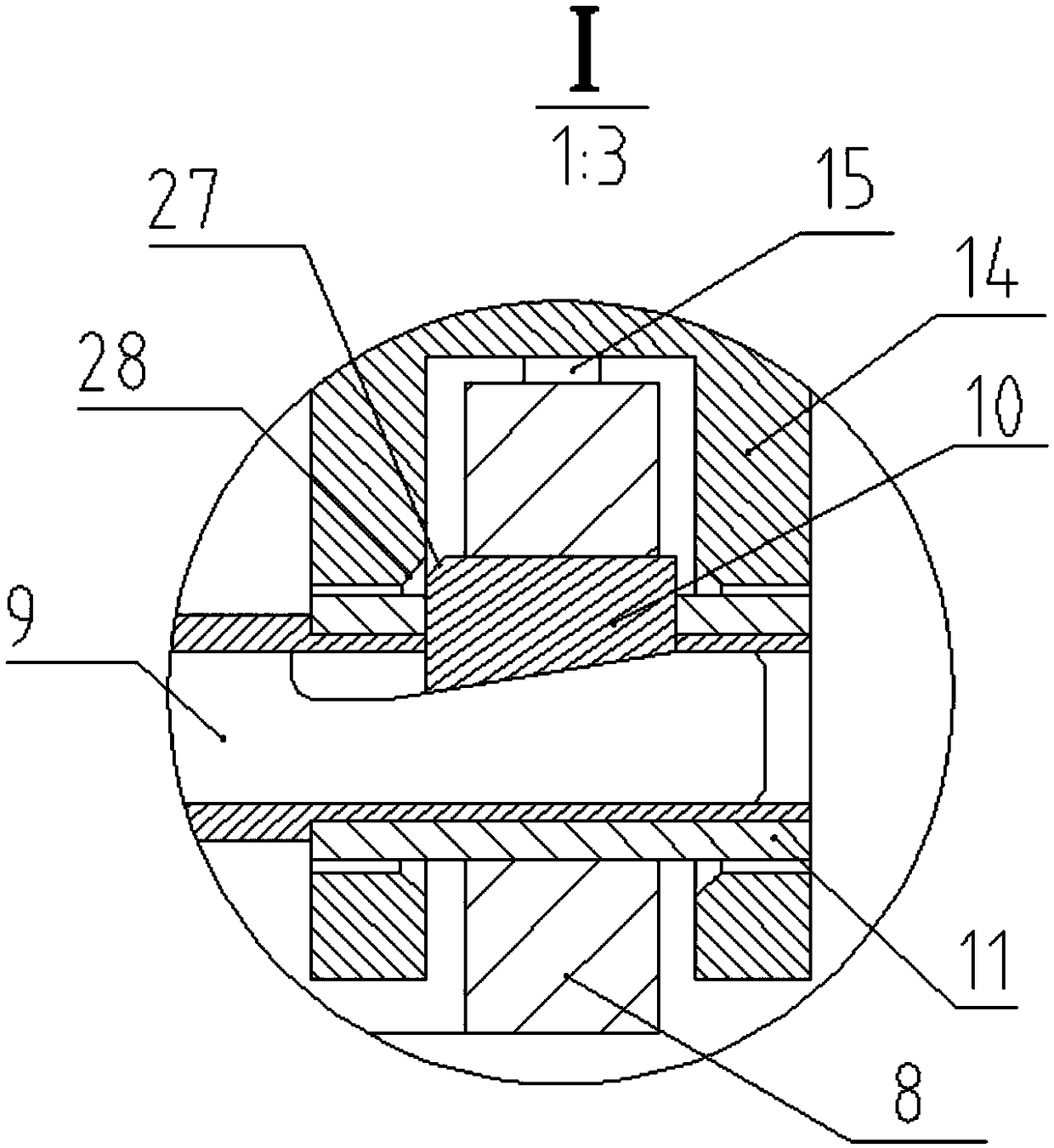

[0042] refer to figure 2 4, the crankcase bearing housing 12 to be processed includes the crankcase body and 5 to 7 bearing housings 8 with the same structure, and the 5 to 7 bearing housings 8 with the same structure are evenly distributed on the top of the crankcase body, and the crankshaft The box body and 5 to 7 bearing seats 8 with the same structure are integrated into one body. After the cracking process is completed, the 5 to 7 bearing seats 8 with the same structure are broken into bearing bases and bearing caps 24, and the 5 to 7 bearing bases are still connected to connected to the crankcase.

[0043] refer to figure 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com