Method for improving anti-clogging capacity of high-water-permeability concrete

A permeable concrete and anti-clogging technology, applied in the field of building materials, can solve the problems of reduced drainage function of permeable pavement, disappearance of water permeable function of permeable pavement, and reduced permeability of pavement, so as to reduce economic expenditure, reduce resource consumption, and prevent clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

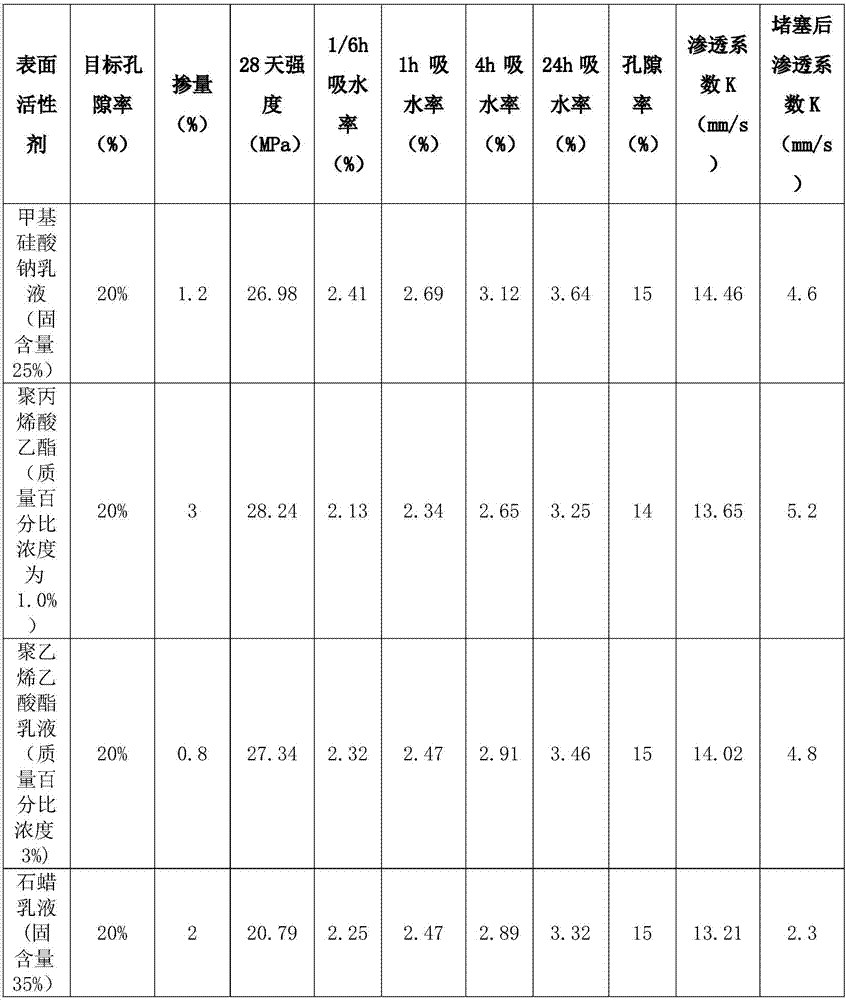

[0026] Embodiment 1: Comparison with various indexes of ordinary permeable concrete

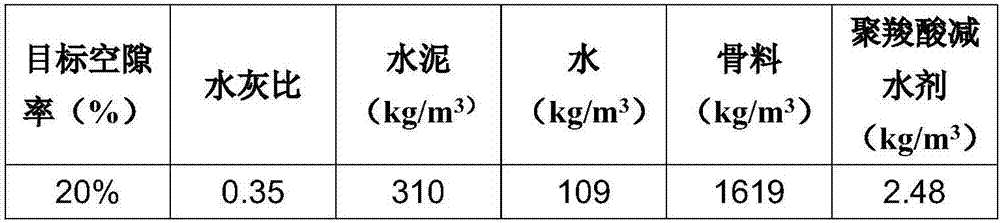

[0027] Table 1 Permeable concrete mix ratio

[0028]

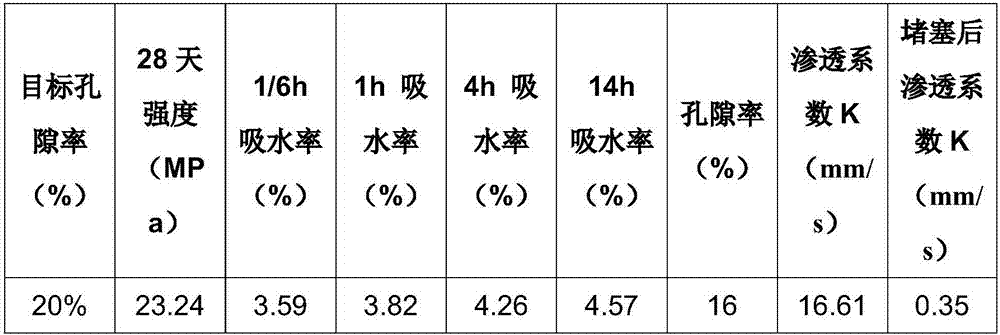

[0029] Take each material according to Table 1, after mixing, stir with a concrete mixer for 3 minutes, and vibrate to form a method; then put the stirred mixture upside down in a test mold of 100×100×100mm, demould it after 24 hours and put it in a standard curing room ( Temperature is 20 ℃, humidity is 90%) curing 28 days. The 28-day compressive strength, 1 / 6h, 1h, 4h, 24h, porosity and permeability coefficient of permeable concrete are shown in Table 2.

[0030] Take clay as the blocking substance, take 1g of the blocking substance each time and apply it evenly on the surface of the test block, tap it lightly with a rubber hammer, and then place it in the natural environment for 3 days, 10 times in a row, to simulate the actual use of permeable concrete the blocking process. And measure the water permeability coefficient of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com