A kind of YSZ ceramic granulation powder for plasma spraying and preparation method thereof

A granulated powder and plasma technology, which is applied in the field of YSZ ceramic granulated powder for ion spraying and its preparation, can solve the problems of uneven service life of thermal barrier coatings, affecting the stability of powder performance, and increasing the cost of wastewater treatment. , to achieve the effect of improving batch performance stability, uniform service life and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

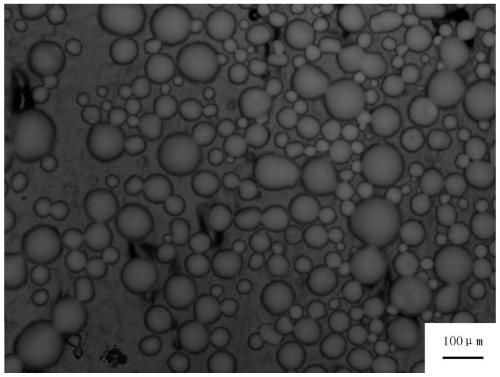

[0035] The invention provides a preparation method of YSZ ceramic granulation powder for plasma spraying, comprising the following steps:

[0036] (1) providing a mixed raw meal comprising yttrium oxide and zirconia; the particle size of the mixed raw meal is 0.5-4 μm;

[0037] (2) mixing the mixed raw meal with starch, and performing high-temperature roasting to obtain YSZ clinker; the temperature of the high-temperature roasting is 1350-1550°C;

[0038] (3) the YSZ clinker that described step (2) is obtained is mixed with dispersant and water, carries out ball milling treatment, obtains ball milling slurry;

[0039] (4) Sand milling the ball mill slurry obtained in the step (3) to obtain a sand mill slurry;

[0040] (5) Mix the sand mill slurry obtained in the step (4) with a binder, and granulate to obtain YSZ ceramic granulation powder for plasma spraying.

[0041] In the mixed raw meal comprising yttrium oxide and zirconia provided by the present invention, the mass rat...

Embodiment 1

[0074] Based on the total mass of zirconia and yttrium oxide as 1000 parts, accurately weigh 940 parts of zirconia, 60 parts of yttrium oxide, and 2 parts of dispersant ammonium methacrylate, add deionized water to adjust the oxidation ratio in the mixed slurry The mass sum of zirconium and yttrium oxide is 55% of the total mass of zirconia, yttrium oxide and deionized water. The material is ball milled for 2 hours through a stirring ball mill. The grinding body is a zirconia ball with a particle size of 3-4mm, and the ball milling speed is 160r / min .

[0075] The slurry after stirring ball milling was spray-dried, the atomization frequency was adjusted to 45 Hz, the air inlet temperature was 240° C., and the air outlet temperature was 90° C. to obtain yttrium oxide zirconia mixed raw meal.

[0076] Accurately weigh 1,000 parts of yttrium oxide and zirconia mixed raw material and 20 parts of starch, mix them thoroughly, and then sinter at 1350°C for 6 hours to obtain YSZ clink...

Embodiment 2

[0082] Calculate with the total mass of zirconia and yttrium oxide as 1000 parts, accurately weigh 930 parts of zirconia, 70 parts of yttrium oxide, and 4 parts of dispersant ammonium polyacrylate, add deionized water, and adjust the zirconia and yttrium in the mixed slurry. The mass sum of yttrium oxide is 58% of the total mass of zirconia, yttrium oxide and deionized water. The material is milled for 3 hours by a stirring ball mill. The grinding body is a zirconia ball with a particle size of 4-5mm. The milling speed is 150r / min.

[0083] The slurry after stirring ball milling was directly dried in an electric oven at 90° C. for 12 hours to obtain a mixed raw meal of yttrium oxide and zirconia oxide.

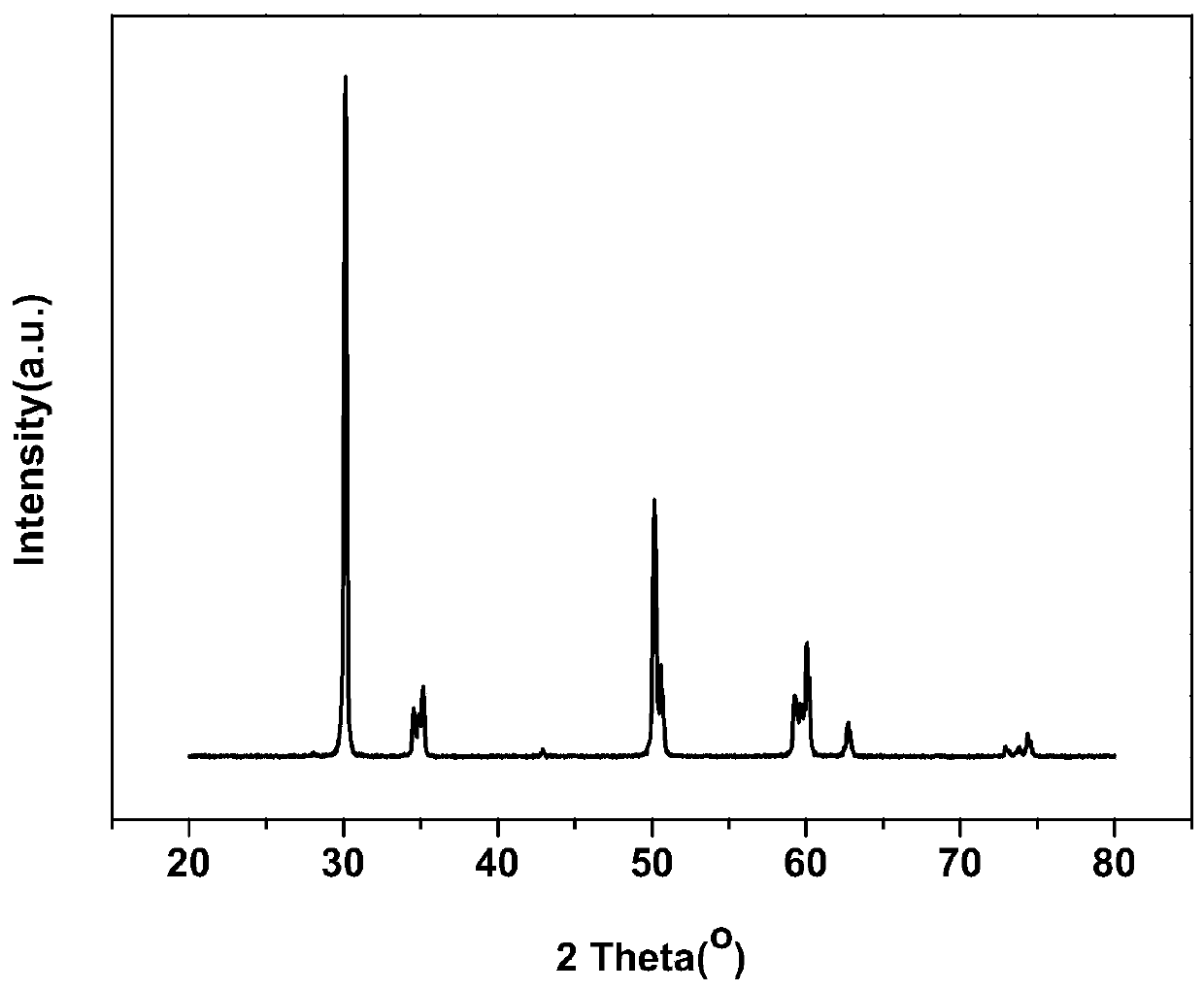

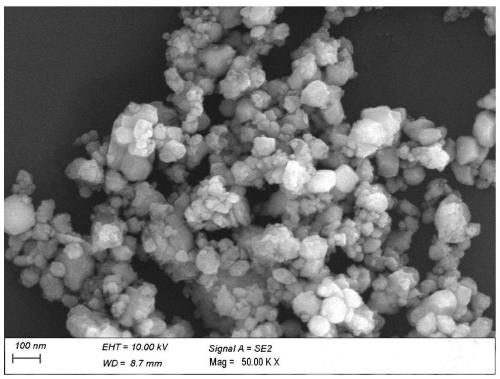

[0084] Accurately weigh 1,000 parts of yttrium oxide and zirconia mixed raw material and 30 parts of starch, mix them thoroughly, and then sinter at 1400°C for 5 hours to obtain YSZ clinker. The XRD analysis of the obtained YSZ clinker shows that the YSZ clinker obtained by hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com