High-speed rail bridge support seismic isolation system

A technology for bridge bearings and vibration reduction and isolation, applied in bridges, bridge parts, bridge construction, etc., can solve the problem of insufficient connection and coordination, failure to achieve regular maintenance and protection of bearing loads, and efficient coordination and inability to test loads Problems such as pressure data to achieve the effect of improving the effect of shock absorption and isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

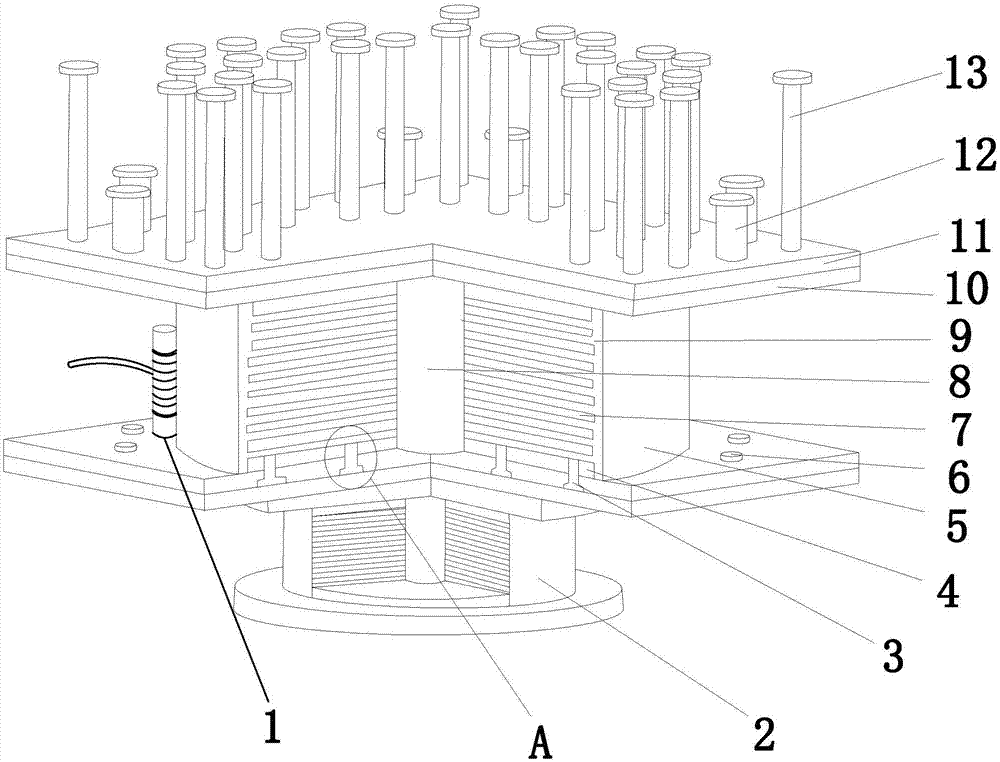

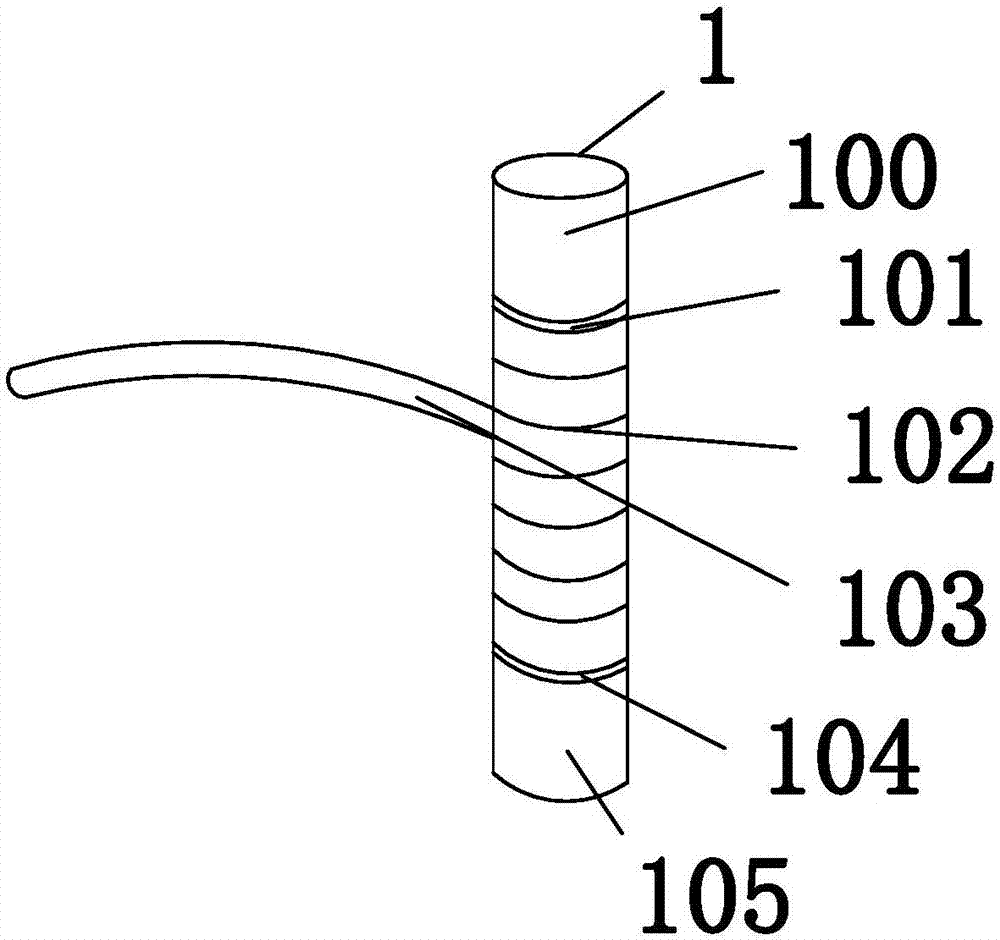

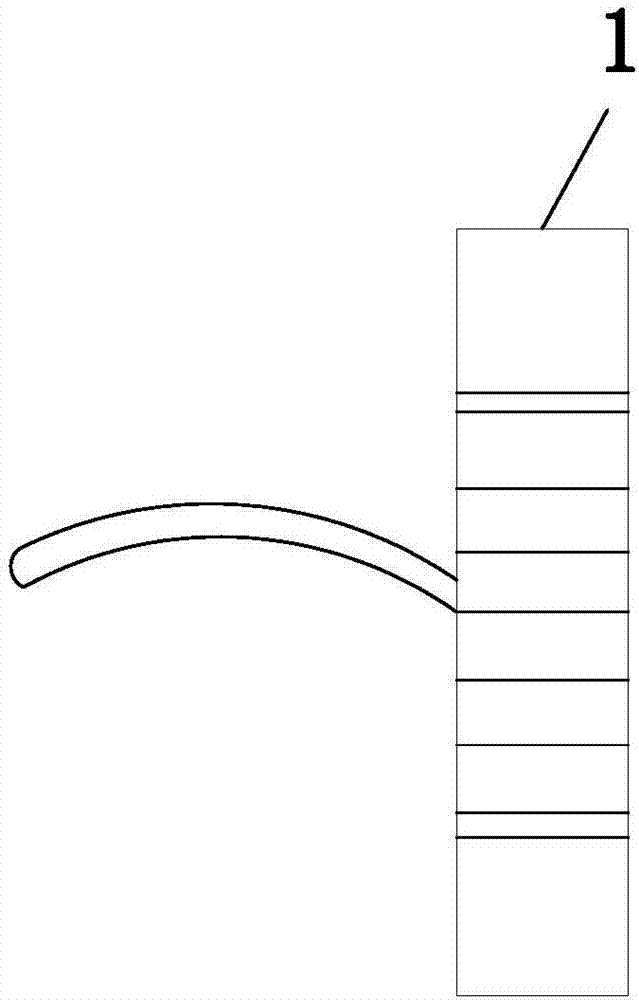

[0035] see Figure 1-Figure 8 , the present invention provides a high-speed rail bridge support vibration isolation system: its structure includes: pressure sensor 1, vibration isolation rubber bearing 2, inner connecting bolt 3, silica gel sealing plate 4, rubber protective layer cover 5, outer connecting bolt 6 , stable steel plate layer 7, shock-isolation lead core 8, shock-absorbing rubber layer 9, connecting steel plate 10, embedded steel plate 11, bridge sleeve 12, bridge embedded rib 13, the connecting steel plate 10 and embedded steel plate 11 are all provided There are two and the upper embedded steel plate 11 is horizontally attached to the upper connecting steel plate 10, and the upper connecting steel plate 10 and the lower connecting steel plate 10 are respectively horizontally fixed on the upper and lower sides of the rubber protective layer cover 5, and the lower connecting steel plate 10 is horizontally fixed on the upper and lower sides of the rubber protective...

Embodiment 2

[0043] see Figure 1-Figure 8 , the present invention provides a high-speed rail bridge support vibration isolation system: its structure includes: pressure sensor 1, vibration isolation rubber bearing 2, inner connecting bolt 3, silica gel sealing plate 4, rubber protective layer cover 5, outer connecting bolt 6 , stable steel plate layer 7, shock-isolation lead core 8, shock-absorbing rubber layer 9, connecting steel plate 10, embedded steel plate 11, bridge sleeve 12, bridge embedded rib 13, the connecting steel plate 10 and embedded steel plate 11 are all provided There are two and the upper embedded steel plate 11 is horizontally attached to the upper connecting steel plate 10, and the upper connecting steel plate 10 and the lower connecting steel plate 10 are respectively horizontally fixed on the upper and lower sides of the rubber protective layer cover 5, and the lower connecting steel plate 10 is horizontally fixed on the upper and lower sides of the rubber protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com