Subway tunnel structure safety assessment method based on external project additional stress

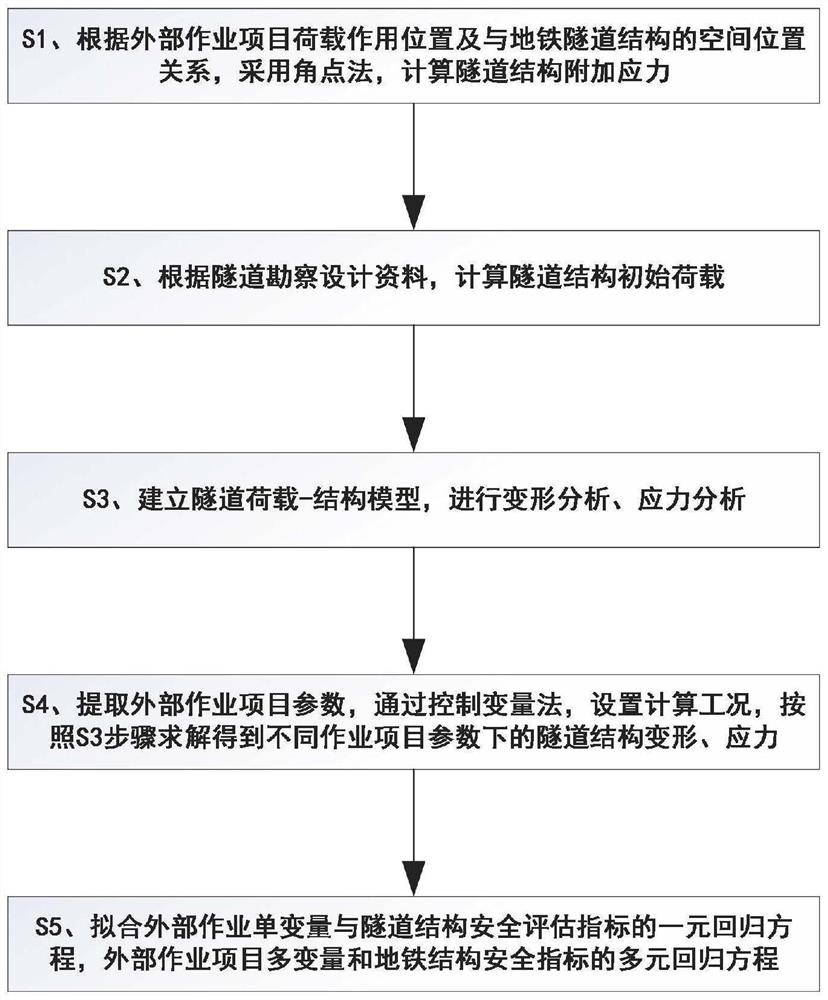

A tunnel structure and additional stress technology, which is applied in instrumentation, geometric CAD, design optimization/simulation, etc., can solve the problems of low calculation efficiency, large model volume, large calculation volume, etc., and achieve improved calculation efficiency and direct evaluation indicators , The effect of the force system is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

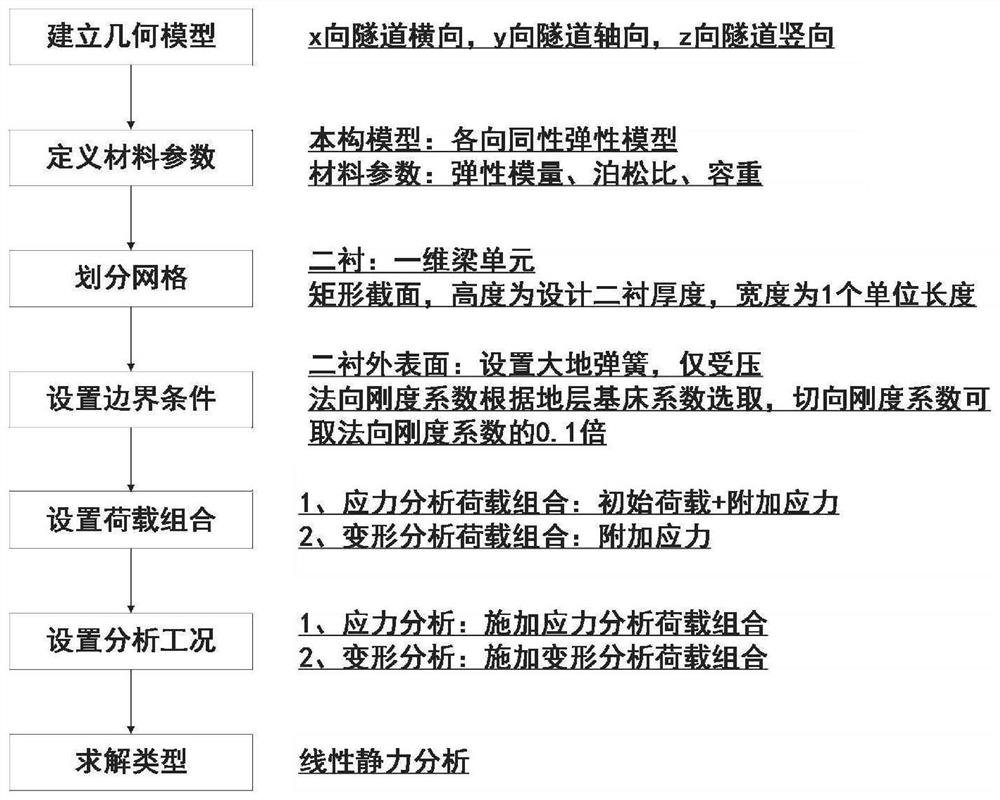

Method used

Image

Examples

Embodiment Construction

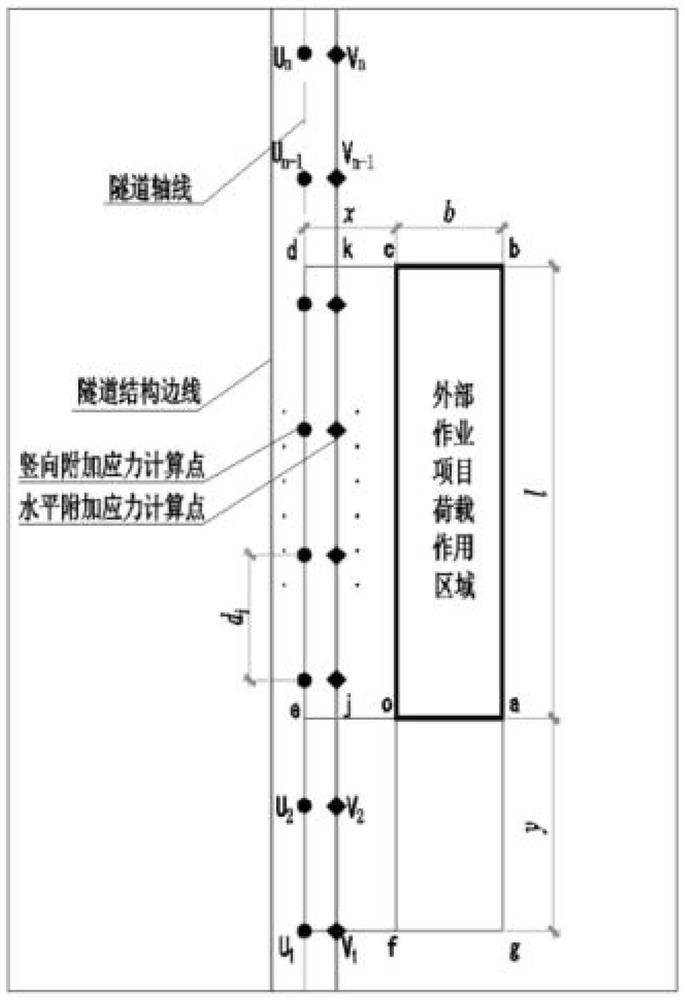

[0057] In this example, the technical solution is described by taking the ground piling of a subway tunnel with a mining method as an example. The clear distance between the ground piling and the sideline of the tunnel structure is x=5m, the piling width b=5m, the piling height H=3m, and the tunnel burial depth h=5.89m~6.15m, the stratum from top to bottom is plain fill, silty clay, silty sand, strongly weathered granite, and the weighted average weight of the soil layer is γ'=20kN / m 3 , the tunnel in the equilibrium interval is located in strongly weathered granite, the horizontal bed coefficient is S=140MPa / m, and the lateral pressure coefficient is λ D =0.33; the secondary lining is designed as a horseshoe-shaped section, using C45 concrete with a thickness of 300mm and a net section of 6.0×5.8m (B×D). The tunnel section structure is as follows Image 6 .

[0058] (1) According to the spatial relationship between the ground stacking position and the subway tunnel structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com